- Marine Supplies

Maintenance & Boating Guides

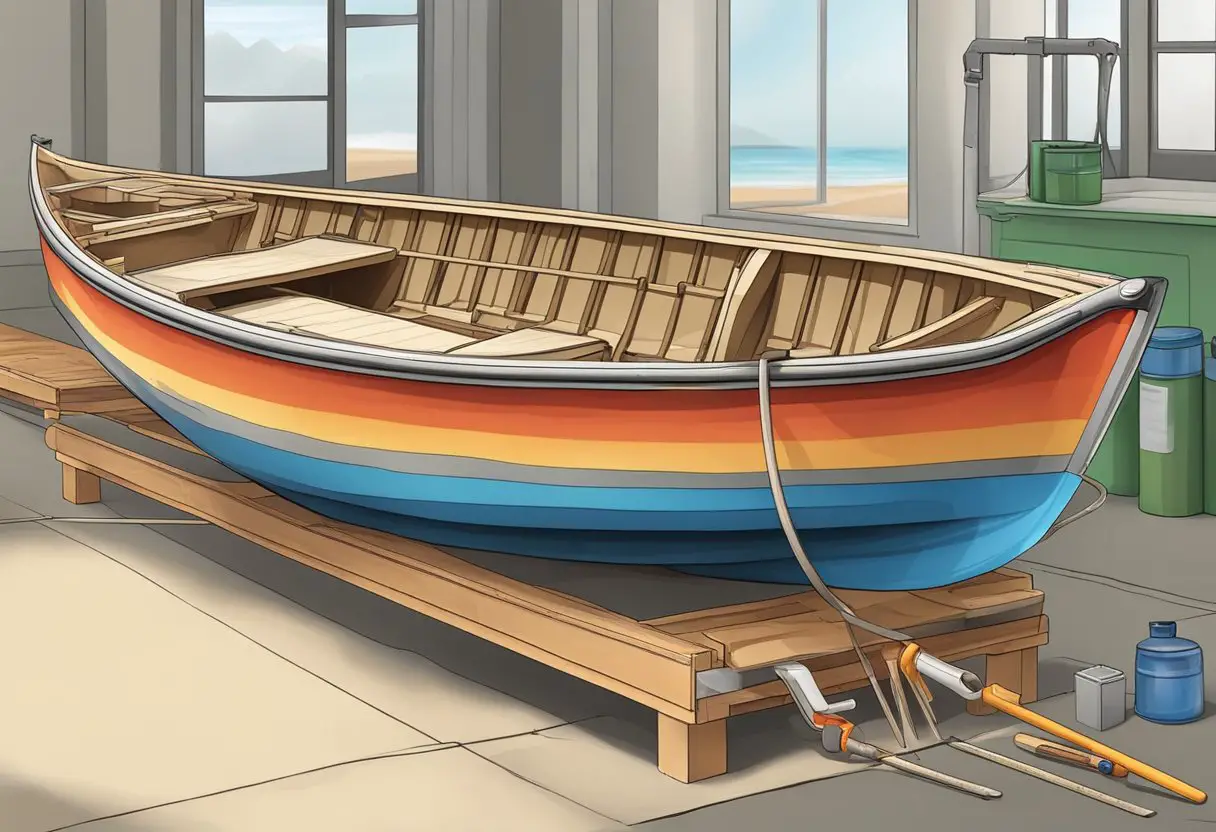

How to Restore a Fiberglass Boat: Fiberglass Boat Restoration Tips

By: B.J. Porter Editor

Classic old boats have a lot of beauty under those dull, oxidized finishes, and with some effort, you can bring some shine back to the classic lines of that tired-looking but classic fiberglass boat. It’s hard work, but the results can be spectacular. Here are some of our top boat restoration tips.

Oxidation is Your Enemy

Gelcoat is the layer of resin on the outside of your boat that holds the color and protects the fiberglass underneath from the elements. It has no stiffening strength, but it takes a beautiful shine when polished. But it’s not impervious, and sunlight and salt water can wear it and age it.

That chalky white stuff clouding your older boat’s finish is oxidation , the long-term result of gelcoat aging in the sun without regular washing and waxing . A boat gets its beauty and shines from the gelcoat layer over the structural fiberglass, but age, neglect, and exposure to the elements lead to discoloration and loss of shine. To bring back a boat’s glossy finish, you polish away the oxidized layer and put a new finish on the gelcoat.

You might also be interested in: Pontoon Boat Covers: Which is Best for You?

Fiberglass Boat Restoration Tips

There are several steps to restore cloudy, oxidized fiberglass to bring the color back to your boat. You need to clean the hull, polish out the faded surface, then protect it all once you’ve brought back the shine. How you approach each step depends on just how much oxidation you have on the gelcoat.

Always wear protective clothing, gloves, and eyewear throughout the entire process. Almost all the detergents, solvents, and compounds used can irritate your skin or hurt your eyes.

Clean, de-grease, and de-wax the Hull

From stem to stern, clean the hull with quality boat soap, and remove all surface dirt or debris. Scrub well, and leave nothing on the surface. You’re going to be rubbing and polishing the hull, and you don’t want to grind dirt and grit into the surface.

To ensure there’s no grease or wax on the hull after you’ve scrubbed the hull with detergent, clean the hull again with MEK or acetone and clean the rags. Fold and turn your rags to keep working with clean spots.

Remove stains

Clean as many surface stains off the boat. Tougher water and rust stains may not come off with a scrub brush and soap, so you may need a special cleaner. Take care to follow the instructions carefully and wear protective gear as directed, most of these special cleaners use harsh chemicals or acids. Rinse all heavy-duty cleaners off with plenty of fresh water when you’re finished.

If you can’t get the worst stains out, buffing may still get them off, but it’s best to clean them first.

Buff with Rubbing Compound to Remove Oxidized Gelcoat

Rubbing or “cutting” compound is a liquid with abrasives suspended in it that can remove surface layers of oxidized gelcoat. To buff your boat, start with a small section of the hull and buff by hand or with a polisher. Work in small sections of about two feet square, and don’t let the compound dry on the hull.

For smaller boats, you can buff by hand, but for larger and heavily oxidized boats a high-speed buffer with a soft buffing pad is recommended. As you buff each section of the boat, follow the instructions on the compounding liquid about application and removal.

Always keep an electric buffer moving, and don’t press too hard in any one spot or you may damage the gelcoat. The goal is to remove as little material as possible while removing the oxidized layer.

If the rubbing compound isn’t taking the oxidation off, you may need to wet sand. Wet sanding with 1200-grit paper is more aggressive than rubbing compound but may be necessary. You can also try multiple passes with the polisher and rubbing compound.

Polish and Shine

Boat polish differs from rubbing compounds in the grit of the abrasives. It’s much finer and will remove any fine surface scratches from wet sanding or compound rubbing to leave a bright, shiny finish.

The process is like buffing with the compound – work in small patches and don’t let the compound dry, working your way around to polish the entire hulk.

Apply Wax to Protect the Hull

The last step to preserve your hard work and keep the boat shiny longer is a good application of wax. Wax is best applied on cooler, overcast days, to slow drying and give you more time to buff. Apply wax to a small section of the boat, and buff it off as per the instructions.

NOTE: You can often find one-step “polish and wax” products. If you’re already compounded the hull and are ready to polish, this can be a time saver, cutting out one step.

The Right Tools for Restoring Your Fiberglass Boat

You’ll need a fair amount of tools, rags, and chemicals to restore your boat, so plan and make sure you’ve got what you need before you start.

To do the job right, you’ll need to include:

- Rotary buffer or polisher

- Buffing pads

- Lots of clean rags

- Boat soap or detergent

- Boat brush.

- Stain removers (as needed for rust, water, and other stains)

- Rubbing and finishing compound

- Protective gear – gloves, coveralls, eye protection, as needed.

- MEK, acetone, or another degreaser.

- Hose, source of water, bucket, and sponge.

Choosing Buffers and Polishers

Buffers come in several types – random orbital, rotary, and high speed. And cordless and corded.

Random orbital buffers and polishers use an offset rotor to move the buffing pad in random back-and-forth motions, versus a straight, rotary motion. Random orbital polishers are good for wax jobs or light polishing. But they don’t spin quickly; only a high-speed rotary polisher will have enough speed to build the heat you need to get the oxidation off your boat. If you have a serious restoration to do, you will need a high-speed rotary polisher.

Whether or not to get a corded polisher is a matter of budget and preference. Corded units are cheaper and never run out of power, but cordless tools let you work without a plug. Neither one will survive a drop in the water well, so secure them with a lanyard.

No matter which you use, never stop the buffer in one place on the boat, as you can mark the hull and damage the gelcoat.

If you also wanna prepare your boat for winter, take a look at this post: A Guide to Winterizing Your Pontoon Boat

Picking Compounds and Waxes for Polishing

There are dozens of rubbing, polishing, and “cutting” compounds on the market. Unfortunately, they’re rarely labeled by specific characteristics like grittiness or what sort of liquid it is. Rather, they’re labeled with words like “quick,” “fast,” “heavy,” and so on.

For strongly oxidized hulls, you want the coarsest cutting compound you can get that won’t damage the gelcoat or leave visible scratches you’ll have to buff out. If you can’t tell the coarseness from the labeling, check the manufacturer’s website for more detail.

Almost all of them are hazardous and can irritate the eyes and skin.

Waxes range from pure wax pastes to easy on/off liquids and combined polish/wax products. Most of the easy application products work well, and you may save some work with a polish/wax combination.

- How to Paint The Bottom of a Boat

Frequently Asked Questions

If you do it yourself, you can expect to spend several hundred dollars for the initial equipment and supplies. A quality variable speed rotary polisher costs $100 to $300. Buffing pads are $20-$30 each, and you'll need several, though some can be cleaned and reused. Rubbing compound costs from $20 to $60 per quart. How much you need depends on the size of your boat and how oxidized the hull is. Additional materials like rags, stain removers, protective gear, and degreasers add another $100-$150 to the job. If you hire someone to do it for you, expect a price range of from $25.00 to $75.00 per foot for a complete de-oxidation/restoration.

Yes, gelcoat can be reapplied to a hull, but it is not cheap or easy. If there is too much damage or crazing in the gelcoat to buff smooth and clean, then a new gelcoat layer may be the best way to restore the boat. The old gelcoat needs to be fully sanded until faired down and smooth, then a new gelcoat can be applied.

Rubbing with an abrasive compound will remove the surface layer of oxidized gelcoat from a hull. Some chemicals may remove a small amount of oxidation, but rubbing is the best way to remove heavy buildup.

Regular washing after use and periodic waxing of your boat will prevent oxidation.

Only if the rubbing compound isn't cutting through the oxidation. It's nothing to be afraid of, but it's an aggressive technique which you should only use if nothing else works.

Some "boat restorers" coat your boat with a shiny polymer coat, quickly bringing back shine to a dull surface. But they don't remove oxidation. An oxidized hull won't look good through a shiny layer of polymer, and the polymer will need to be removed before proper restoration can be done, so they're best not used on heavily oxidized boats.

Troubleshooting Pontoon Boat Battery

Pontoon boats are a great way to enjoy the water and spend quality time with family and friends. But just like any other boat, they rely on a battery to power various systems, including navigation lights, trolling motors, and other…

Boat Accessories

Best Ice Fishing Fish Finders in 2023

In search of the best ice fishing fish finders in 2023? Not all fish finders are created equal, particularly when it comes to ice fishing. Specialized features are crucial to ensure successful outings in harsh winter conditions. You require a…

Best Side Imaging Fish Finders in 2023

Navigating the world of angling equipment can be challenging. That's especially true when it comes to side imaging fish finders, given the extensive range of options available in 2023. This post makes it easy for you to narrow down your…

How to Choose a Fishfinder for Your Boat: A Comprehensive Guide

Today, we embark on a journey to unravel the secrets of choosing the perfect fish finder for your boat. As we navigate through an ocean of options, we'll explore different types of fish finders, delve into their key features, and…

Accessories

5 Best Portable Fish Finder in 2023

Looking for a portable fish finder for kayaking, ice fishing, or other activities? The good news is that there are a lot of solid products out there. The year 2023 has ushered in an array of advanced models, each brimming…

Charging Your Trolling Motor Battery with a Solar Panel

Charging your trolling motor battery with a solar panel is not just the right thing to do for the environment, it is extremely convenient. When you’re out on the boat, with any luck, you’ll have access to a good amount…

Don't miss out

How to restore a classic sailboat

Restoring a classic sailboat can be a fulfilling and rewarding process, allowing you to create a personalized vessel for exploring the open sea with your family.

How to Restore a Classic Sailboat

Restoring a classic sailboat is a labor of love that can bring immense satisfaction and pride to those who embark on this journey. It’s a chance to breathe new life into a vessel that has seen better days, and to create a unique and personalized space for you and your family to enjoy the open sea. In this article, we’ll guide you through the process of restoring a classic sailboat, from finding the right boat to the final touches that make it truly your own.

Table of Contents

Finding the right sailboat, assessing the condition, creating a restoration plan, hull and deck repairs, interior restoration, rigging and sails, electrical and plumbing systems, engine and propulsion, final touches.

The first step in restoring a classic sailboat is finding the right boat. This can be a challenging process, as there are many factors to consider, such as the size, age, and condition of the boat, as well as your budget and personal preferences.

When searching for a sailboat, consider the following:

- Size : Think about how much space you and your family will need, both for living and storage. A larger boat may offer more comfort and amenities, but it will also require more work and expense to restore and maintain.

- Age : Older boats may have more character and history, but they may also require more extensive restoration work. Be prepared to invest more time and money into an older boat.

- Condition : Assess the overall condition of the boat, including the hull, deck, rigging, sails, and interior. A boat in poor condition may be a good candidate for restoration, but it will also require more work and expense.

- Budget : Determine your budget for both the purchase of the boat and the restoration process. Keep in mind that restoration costs can quickly add up, so it’s important to have a realistic understanding of what you can afford.

Once you’ve found a sailboat that meets your criteria, it’s time to assess its condition in more detail. This will help you determine the extent of the restoration work required and whether the project is feasible for your budget and skill level.

Consider hiring a marine surveyor to conduct a thorough inspection of the boat. They can provide valuable insights into the condition of the hull, deck, rigging, sails, and other components, as well as identify any potential safety issues or structural problems.

Take note of any areas that require immediate attention, such as leaks, cracks, or signs of rot. These issues should be addressed before any cosmetic work is done, as they can compromise the integrity of the boat and lead to more serious problems down the line.

With a clear understanding of the boat’s condition, you can now create a restoration plan. This should outline the work that needs to be done, the order in which it should be completed, and an estimated timeline and budget for the project.

Start by prioritizing the most critical repairs, such as fixing leaks or addressing structural issues. Then, move on to less urgent tasks, such as cosmetic improvements and upgrades.

Be realistic about your abilities and the amount of time you can dedicate to the project. Restoring a sailboat can be a time-consuming and labor-intensive process, so it’s important to have a clear understanding of what you’re getting into before you begin.

The hull and deck are the foundation of your sailboat, and any issues with these components should be addressed as soon as possible. Common problems include cracks, blisters, and signs of rot or corrosion.

To repair cracks or holes in the hull or deck, you’ll need to clean the area thoroughly, remove any damaged material, and fill the void with an appropriate filler or epoxy. Once the repair has cured, sand the area smooth and apply a protective coating, such as paint or gelcoat.

For more extensive repairs, such as replacing large sections of the hull or deck, it may be necessary to consult with a professional boatyard or shipwright. They can provide guidance on the best materials and techniques for your specific boat and ensure that the repairs are done correctly.

Restoring the interior of your sailboat can be a rewarding process, as it allows you to create a comfortable and personalized space for you and your family. Start by assessing the condition of the interior, including the cabinetry, upholstery, and flooring.

If the cabinetry is in good condition, you may be able to simply refinish or paint the surfaces to give them a fresh look. If the cabinets are damaged or outdated, consider replacing them with new, custom-built units that meet your needs and preferences.

Upholstery can be cleaned or replaced, depending on its condition and your personal taste. New cushions, curtains, and other soft furnishings can make a big difference in the overall appearance and comfort of the interior.

Flooring options for sailboats include marine-grade carpet, vinyl, or teak. Choose a material that is durable, easy to clean, and complements the overall aesthetic of the boat.

The rigging and sails are essential components of your sailboat, and their condition will have a significant impact on the boat’s performance and safety. Inspect the rigging for signs of wear or damage, such as frayed lines, corroded fittings, or bent or cracked hardware. Replace any components that are in poor condition or no longer meet safety standards.

Sails should be inspected for tears, fraying, or signs of UV damage. Small repairs can often be made with sail tape or by sewing, but larger issues may require professional repair or replacement. Consider upgrading to modern sail materials and designs for improved performance and durability.

The electrical and plumbing systems on a classic sailboat may require updating or replacement to meet modern standards and ensure safety and reliability. Inspect the wiring, switches, and electrical components for signs of wear or damage, and replace any outdated or faulty parts.

Plumbing systems should be checked for leaks, corrosion, or other issues. Replace any damaged hoses, fittings, or fixtures, and consider upgrading to modern materials and designs for improved performance and ease of maintenance.

The engine and propulsion system are critical to the performance and safety of your sailboat. Inspect the engine for signs of wear or damage, and perform any necessary maintenance or repairs. This may include changing the oil and filters, replacing belts or hoses, or overhauling the entire engine.

The propeller and shaft should also be inspected for signs of wear or damage, and any issues should be addressed promptly. Consider upgrading to a modern, efficient propulsion system for improved performance and fuel efficiency.

With the major restoration work complete, it’s time to add the final touches that make your sailboat truly your own. This may include installing new electronics and navigation equipment, adding custom artwork or graphics, or outfitting the boat with personalized accessories and gear.

Take the time to celebrate your hard work and enjoy the fruits of your labor. Your restored classic sailboat is now ready for new adventures and memories with your family.

Restoring a classic sailboat is a challenging but rewarding endeavor that can provide you and your family with a unique and personalized vessel for exploring the open sea. By carefully assessing the condition of the boat, creating a detailed restoration plan, and tackling the project one step at a time, you can breathe new life into a once-neglected boat and create a lasting legacy for future generations.

You are using an outdated browser. Please upgrade your browser or activate Google Chrome Frame to improve your experience.

- Boat Accessories

- Where to Buy

Special until March 31st: 40% off Teak Deck Sealant for the month of March. Use Code MAR24 at checkout. *restrictions apply

Free ground shipping in the Continental US for any orders over $150!

Classic Fiberglass Boat Restoration Tips...

Classic fiberglass boat restoration tips.

There is nothing that makes a boat look new like quality fiberglass. If you’re restoring a classic boat, this can do wonders for its appearance. But that means unsightly fiberglass has the unfortunate effect of just the opposite: it ages your boat. To keep your boat looking great, you need to restore fiberglass to its original finish. But fiberglass can be a finicky material. To handle it, you’ll need more than just a few products. Here are a few classic fiberglass boat restoration tips to help you with your project.

While Cleaning, Don’t Use Products that Remove the Gelcoat

If you’re giving your classic fiberglass boat a complete fiberglass restoration, you’ll need to remove the gelcoat so you can work with the fiberglass surface directly. That’s part of the process.

But in the meantime, make sure you buy boat cleaners that won’t harm your fiberglass gelcoat. This gelcoat is there to maintain your fiberglass’s appearance and protect it against everything that your boat faces on a regular basis.

When Your Boat Looks Faded or Worn, It’s Time for a New Gelcoat

Maybe you ignored the previous tip for a long time. In that case, now is a good time for a full fiberglass restoration process that removes and replaces the gelcoat.

In addition to using a detergent to clean off your boat first, consider using an acetone to remove the gelcoat on your fiberglass. Wear strong rubber gloves for this process to protect your hands. After properly applied, your fiberglass will be ready for a new waxing and polishing.

Combine Waxing and Polishing at the Same Time

Our PolyShine product , when combined with LifeWax , will extend the wax protection on your boat’s hull for about three years. That means you won’t have to continually rub new wax into the fiberglass to keep your boat’s hull protected.

When You Expose Fiberglass, Use a Fiberglass Rubbing Compound

Remember to use this before adding a coat of wax to the boat, as this compound is designed to work with the fiberglass directly.

Consider an Electric Buffer

The key to all the classic fiberglass boat restoration tips above? You have to actually get yourself to do them. And doing them all by hand is sometimes an unenviable task, particularly if you’re working with a large boat.

An electric buffer is a great way to make quick work of fiberglass restoration without losing any of the quality. While you browse all our wax and polish products , don’t forget that an electric buffer is just as valuable an investment in the quality of your fiberglass—and ultimately, the quality of your boat.

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

Featured Products

Liquid LifeSeal® Sealant 5.2 fl. oz. Clear

Stainless Steel Cleaner 16 fl. oz.

Related blogs, thanksgiving trivia.

Thanksgiving is one of America’s oldest and most loved holidays. Even though the story is steeped in a dark history […]

Detailing Your Boat

There’s nothing better than hitting the water in a beautiful boat. A warm summer day with the sun shining, there’s […]

How To Properly Clean Your Boat Trailer

We all know that cleaning your boat is important to not only keep it looking great, but to also ensure […]

All products proudly made in the usa

DIY Boat Restoration: Tips and Tricks for a Budget-Friendly Makeover

Restoring an old boat can be a rewarding and cost-effective way to breathe new life into a beloved vessel.

While it may seem like a daunting task, with the right tips and tricks, you can embark on a DIY boat restoration project that’s easier on your wallet and more satisfying than you might expect.

Helpful Boat Restoration Guides

1. set clear goals, 2. create a detailed plan, 3. prioritize safety, 4. do your own research, 5. salvage and recycle, 6. budget-friendly materials, 7. diy fiberglass repairs, 8. refinishing and painting, 9. upholstery on a budget, 10. routine maintenance.

Boat Restoration Guide

Fiberglass Boat Restoration Guide

Metal Shape Welding Instructions For Boat Building

10 Tips To Make Boat Restoration Simple

In this guide, we’ll share valuable insights and cost-saving strategies to help you navigate your boat restoration journey with confidence.

Before you dive into your boat restoration, determine the scope of your project.

Are you looking for a complete overhaul or just some minor repairs and cosmetic touch-ups?

Setting clear goals will help you avoid overspending and stay focused on your budget.

A well-thought-out plan is essential. Take the time to assess the boat’s condition and identify areas that require attention.

Create a checklist of tasks, including materials and tools needed.

A comprehensive plan will prevent impulse purchases and keep you on track.

Safety should always be a top priority.

Inspect the boat for structural issues, such as rot or damage, and address them first.

This ensures that your boat is safe for use, and you won’t compromise your safety while on the water.

Become a savvy researcher. Look for DIY boat restoration resources, such as books, online forums, and video tutorials.

Learning from others’ experiences can save you from common pitfalls and provide valuable insights.

When possible, salvage and recycle materials from your boat. Old hardware, wood, and even upholstery can often be refurbished or repurposed.

This not only saves money but also adds character to your project.

Shopping for materials doesn’t have to break the bank.

Consider marine-grade plywood alternatives, explore second-hand stores for décor, and compare prices from different suppliers to find the best deals.

Don’t forget to inquire about discounts or bulk rates.

Many small fiberglass repairs can be done at home.

Learning basic fiberglass repair techniques will save you money on hiring professionals.

Invest in a fiberglass repair kit and follow instructional videos to tackle small cracks or holes.

For cosmetic improvements, you can save money by refinishing and painting your boat yourself.

Proper sanding, priming, and using quality marine paint can make your boat look as good as new. Don’t forget to choose colors that won’t fade quickly under the sun.

Reupholstering your boat’s seats and cushions can be expensive. Consider buying discounted marine-grade vinyl and learning basic sewing skills to make your own seat covers.

Alternatively, look for deals on pre-made seat covers.

After your boat is restored, keep it in top condition by following a regular maintenance schedule.

Routine care will extend the life of your boat and prevent costly repairs in the future.

Embarking on a DIY boat restoration project can be both a labor of love and an excellent way to save money.

By setting clear goals, creating a detailed plan, and implementing these tips and tricks, you can transform your old boat into a source of pride without breaking the bank.

Remember that patience and perseverance are key to a successful boat restoration, and the satisfaction of sailing in a vessel you’ve restored with your own hands is truly priceless.

You may also be interested in reading our guide that shows you how to build a flat bottom boat and also our boat building plans .

Mick McGrath

Recent Content

518 Illustrated Boat Plans

518 boat plans for less than the price of your lunch! MyBoatPlans Reviews MyBoatPlans is a comprehensive collection of 518 boat plans, 40 videos and about 500 pages of boat building guides. I've...

Set Sail with Confidence: Essential Boat Safety Tips for All Ages and Furry Friends

Picture yourself gliding over crystal-clear waters, the wind in your hair, and the sun kissing your skin. The open sea offers endless possibilities for adventure, but before you hoist the sails, it's...

- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

- Skip to footer

Yacht Cruising Lifestyle

Everything fun you can do from your yacht

Boat Restoration Tips, Tricks, and Costs

August 29, 2021 by Martin Parker 6 Comments

Are you considering boat restoration as a cheap way to get on the water? While restoring a tired boat can save you money if you do most of the work yourself, there is a lot to consider and plan for if the costs are not to get out of hand.

Restoring a boat is a labor of love and something you are not likely to take on unless the boat concerned has some special meaning for you or you’re trying to save money. It is vital to understand that boats do not generally appreciate value unless they have some historical significance. Unlike car restoration, where collectors will pay big money for classic cars, the same is not true in the yachting world.

Don’t let that put you off, though. Bringing a boat back to pristine condition is hugely satisfying and something to be proud of.

Step-By-Step Process of Boat Restoration

Do You Need a Survey Before Commiting to Boat Restoration?

If you’ve recently purchased a boat, then you should have had a survey carried out already. If this is a boat you’ve owned for a while and intend to restore it, then a survey could be a good idea before you start. There are different types of surveys available, but the most common is the condition and value survey. The surveyor assesses the boat’s overall condition, reports any problems, and gives a market valuation.

You may need specialized surveys for the engine and other systems, and you can find accredited surveyors on the NAMSGLobal website or the Society of Accredited Marine Surveyors .

Clean the Boat Thoroughly

While it may seem an odd suggestion, thoroughly cleaning the boat has a practical purpose. While cleaning your boat, you can spot any problems you may have missed previously. Cleaning also gives you a base standard to start from and will save you time in the long run. Unblock all the drainage holes, thoroughly clean the bilge, and lift any hull access points to clean and inspect.

List Broken Items

Making a list of parts that need replacing or repairing is vital. Some areas of the boat will only be accessible during the restoration. Suddenly remembering a component that you needed to replace when the restoration is complete is not great! Completing this step enables you to plan the boat restoration in a logical order.

Check Any Through-Hull Fittings

Any fitting that penetrates the hull can potentially flood the boat, so these must be checked and repaired. All through-hull fittings use specialized sealants where they mate with the hull. Don’t skimp in this area, as you will regret it when the first leak appears.

Check the Seacocks Are Working

Seacocks have two purposes. Some are there to let water in, for engine cooling, for example, while others let water out, such as cockpit drains. In either case, it’s vital to ensure they are working correctly. The seacocks for cockpit drains and sinks etc., are usually closed at sea as the rolling movement of the boat can let water enter the hull. A seacock seized open has caused many boats to flood and sink.

Check the Condition of the Hull

What you are looking for will depend on the materials used to make the hull. A thorough inspection inside and out is required.

Fiberglass Hulls have a gel coat to protect the surface, but water may have penetrated the core if cracked and damaged. You can repair small areas of damage yourself, but extensive damage will need a professional eye. Pay particular attention to any fittings, such as cleats, stanchions, and chainplates, as cracking often occurs here. On older boats, the gel coat may have faded and stained. As long as the surface is good, you can restore it using a jetwash and readily available materials.

Wooden Hulls can suffer from rotten or dried-out wood if the protective coating is damaged. Repairing wooden hulls is a specialist skill that you shouldn’t attempt unless you are very confident. If the woodwork is sound, then resealing is a simple but time-consuming task.

The surveyor’s report should have highlighted all the damaged areas that he can see, but it depends on the type of survey you commissioned.

Check Load-Bearing Fixtures

Load-bearing fixtures such as cleats and chainplates put immense stress on the deck. Behind every load-bearing fixture, there should be a backing plate to spread the load and prevent damage. Make sure the backing plates are in place and in good condition.

Inspect Every Halyard, Sheet, or Control Line

The materials used in making halyards and sheets are very resistant to the damage caused by saltwater and the sun. But over time, they do weaken. Inspect all the lines carefully for any wear or fraying, and replace where necessary. Any lines in good condition can be washed in a very light non-bio detergent but ensure you rinse with plenty of fresh water.

Inspect Your Sails

Your sails work in a hostile environment, constantly exposed to UV light, saltwater, and extreme tension in heavy winds. Checking your sails during a restoration is a vital step to getting back on the water.

Check the following areas particularly:

Stitching: The sails stitching is the most common area affected by ultraviolet light from the sun. If you find anything, you should send the sail to a professional for repair.

Cringles: A cringle is stitched in to feed a sheet or line through at each attachment point. Check for damage to the metal or fraying of the stitching. Anything you spot here will most likely need professional attention from a sailmaker.

Sail Surface: Look out for fraying stitching, tears, and holes. Small holes can be repaired using repair tape or by sewing.

Sail Edges: Again, look out for fraying or loose stitching, but also signs of stretching.

Mold: Although mold won’t damage a sail, it looks unsightly, but luckily it is relatively easy to remove. Any sails that pass inspection should be thoroughly washed, dried, folded, and stored in a cool, dry location. Do not be tempted to put your sails away wet, as this encourages mold.

Engine: You can commission a separate survey for the engine, but if you have just lifted the boat out of the water to restore it, then a good service is probably the only thing required. For any boat that has been unused for a long time, it may be more economical to lift the engine out for a complete overhaul. Each situation will be different, and getting several quotes is a good idea.

If you decide to leave the engine in place, then at the very least do the following:

– Drain fuel tank

– Change engine oil

– Change gearbox oil

– Replace oil and air filters

Estimate the Cost of Boat Restoration

You’ve completed a complete survey of your boat, and it’s time to start the task of estimating the cost of the repairs. This is a critical stage and not one to rush. Finding the cost of replacement parts is relatively easy, so long as they are available. Older boats will be out of production, and the boatyard that built it may no longer be in business. A degree of improvisation and adapting similar parts may be required, which takes longer and costs more.

Many jobs may be labor-intensive, such as stripping back the Gelcoat or sanding down wooden decks. If you can do these jobs yourself, you’ll save a lot of dollars, but don’t exclude the cost of your time in the restoration cost. If you need to use skilled trades, then ask for quotes.

Once you’ve built a complete estimate of the cost of restoration, only you can decide if it’s feasible or not. If you hope to profit by selling the restored boat, this is a simple financial decision. A boat with some historical or sentimental value can make a choice more difficult.

Planning For Boat Restoration

Now you have a good idea of the costs involved, and you’ve decided to go ahead and embark on your boat restoration project. Congratulations! It’s probably going to be a long but worthwhile road ahead.

Take some time now to plan out the restoration in stages. You should complete some jobs before others, such as replacing damaged structural parts before relaying the deck. It’s also worth setting yourself some realistic deadlines to complete the stages. Not only is it something to aim for, but there is a sense of satisfaction as you complete stages. It sounds obvious, but it is easy to miss or forget something along the way if it’s not written down.

Boat Restoration Costs

Some people will say pick a number out of the air and then double it, and you’ll still be well under the final cost! There are so many factors to consider. If you are restoring a small boat, say 25 feet LOA, a conservative estimate might be $15,000 to $20,000. But as you discover more problems along the way, the final bill could be much higher. As the size of the boat increases, the cost increases exponentially.

The final cost will depend on how much needs doing and the quality of the work. We cannot emphasize enough the importance of a good inspection, cost estimate, and a well-thought-out plan.

As an example, you may buy a tired-looking 30-foot boat for $30,000. Add on around $25,000 for the restoration work carried out by skilled trades, plus $15,000 for your own time—a total cost of approximately $70,000. Compared to the price of a new 30-foot yacht of around $120,000, that’s quite a saving. On the flip side, the resale value of the restored boat may only be around $45,000. Having spent so much time, money, and effort on the restoration, you’re unlikely to sell any time soon.

Boat Restoration Tools

Apart from some specialist tools for specific jobs, you will need a good set of basic hand and power tools. When you are buying tools, it is better to buy quality rather than quantity. The cheap grocery store tool kit with 100 items for 20 bucks will not stand the test of time.

The best advice I ever got was to buy the quality tool you need when you need it, rather than trying to build a complete tool kit from the beginning with cheap items.

Boat Restoration Materials

The list below gives you an idea of the materials you may need to buy based on a 30-foot yacht. There will be more. Make sure you add these items to your estimate of costs.

Rigging: An older boat that needs restoring will most likely need some of the rigging replaced. If you don’t like heights, this is a job for professionals. Expect a cost of around $1000 to $1500.

Metalwork: Replacing broken cleats, chainplates, etc. Replacing the chainplates could cost a few hundred dollars if you do the work yourself or several thousand if you employ skilled trades.

Sails: Replacing any damaged sails and repairing where possible. For a new jib and mainsail, expect somewhere between $2,500 and $4,000

Halyards, Sheets, and Control Lines: Replace any that are past their useable life. Prices for rope can range between $2 to $10 per meter, depending on thickness and quality.

Engine: Replacing oils, fuel, and filters and renewing coolant hoses, fuel lines, and pump belts.

Batteries: Any yacht that has stood for a long time will probably need new batteries, but get them tested first.

Gelcoat Repair Kits and Polishing Tools, or Varnish for Wooden Hulls: Gelcoat can be bought in bulk if needed. Around $30 for a 1kg tin.

Winches and Blocks: After cleaning them with fresh water, check for smooth operation and service them. If you need to buy new winches, budget for at least $500 upwards for a self-tailing version.

Expert Help

Specialized expert help in the boating world is expensive. The more you can do yourself, the better, but include your labor cost in the final estimate. Qualified tradespeople may cost you more, but they will complete the job in a shorter time, getting you out of the yard and on to the water sooner. Experienced, skilled tradespeople can charge around $100 an hour for their services.

Boatyard Fees

Many people overlook the cost of storing your boat in the yard while the work is in progress. If you only work on your boat at weekends, it could be several years in the yard before you finish the restoration.

Continuing Costs

Owning a boat has continuing costs if you plan to maintain your restored yacht to the standard you’ve made it. We wrote an article covering the cost of boat ownership to help you know what to expect as a first-time boat owner.

Boat Restoration Tips and Tricks

When to Replace or Repair Yacht Components

A yacht operates in corrosive conditions of saltwater and sun, and particular items need regular checks and repairs. We’ve compiled a table below for the average lifespans of components, but many variables affect these estimates.

Component Expected Life Before Repair or Replacement

– Standing Rigging 10 years

– Sails 4,000 hours

– Halyards and Lines 5 to 10 years

– Engine (Diesel) 5,000 hours

– Mast Inspect and repair every five to six years depending on use

– Batteries 4 to 5 years

– Gelcoat 5 years

– Wooden deck stain Yearly

Do You Have the Skills for Boat Restoration?

Be very honest with yourself about your skills. Some jobs should be left to the professionals unless you are very confident. Electrics and the engine, for example, both require specialist skills.

Gelcoat Repairs

An older fiberglass boat will very likely have some Gelcoat damage, so how do you repair this? We have chosen three videos showing the standard method for gelcoat repairs.

The first Gelcoat repair video is from someone attempting it for the first time. Watching this video should help you to avoid some common mistakes. The repairer uses a patch paste kit that is available from most boatyards.

In this next video, we follow another Gelcoat repair, but this time mixing the Gelcoat by hand and repairing small cracks instead of a hole.

The last video on Gelcoat repairs focuses on spider cracks that are so common in fiberglass boats.

Buffing and Polishing the Hull of a Fiberglass Boat

You’ve repaired the Gelcoat and now need to bring back the lustrous shine that your boat had when it was new. Here are a couple of videos showing you how to buff and polish Gelcoat.

This method uses only polishing creams and buffing tools to restore the Gelcoat finish . An alternative approach is to start with 2000 grit sandpaper before using the buffing tools and rubbing compound to polish the Gelcoat .

Finally, this time-lapse video shows a complete boat restoration from start to finish , completed in an incredible six weeks.

Do you Need Certifications for Any of the Work?

There are no requirements to have your electrical or mechanical work certified for privately-owned pleasure boats that don’t take paying customers. However, your insurer may insist that a qualified person approves any work you have completed. We would suggest that it’s in your interest to have the work checked before you first launch your restored boat.

If you intend to use your boat commercially, then a whole set of regulations will apply.

Sell Your Boat or Restore It?

As we previously mentioned, restoring a boat is not going to make you a profit. But you’ll finish up with a boat that was cheaper than buying brand new. The decision between selling the boat and restoring it will depend on numerous factors.

– Does the boat have any sentimental value to you?

– Do you have the time and money to complete the restoration?

– Will you lose interest partway through the restoration? Be honest with yourself!

Only by answering those questions can you decide whether to sell or restore your boat.

Avoid Expensive Brand Name Products

Boatyards will happily sell you branded products, but it is possible to use cheaper alternatives in some cases.

– Regularly wash your boat with fresh water to reduce the need for chemical products

– Use household products instead of chemicals where possible

– Use chemicals sparingly

– Vinegar is good for removing stains on cloth materials

General Cleaner: Use one cup of white vinegar in a gallon of water to scrub decks and surfaces, then rinse with fresh water.

Stain Remover: Mix baking soda and water to form a paste. Use it to remove fiberglass stains, then rinse.

Mildew Remover: A 1:1 mix of lemon juice and salt will remove mildew stains on cloth and canvas.

Need more information on a specific boat restoration project or task? Reach out to the #BoatLife community with a question or comment on our community forum!

If you found this article helpful, please leave a comment below, share it on social media, and subscribe to our email list.

For direct questions and comments, shoot me an email at [email protected]

Sharing is caring!

Reader Interactions

September 24, 2021 at 9:11 pm

I found it helpful when you said that you would need to replace your boat’s chainplates for a few hundred dollars when restoring a boat. This is something that I will share with my father so he could be financially prepared in restoring his boat. He said yesterday morning that he is planning to shop for used boat parts that would meet his budget. Thanks for sharing this.

September 27, 2021 at 4:26 pm

Hi Shammy, thanks for reading!

We’re happy that this guide could be of some help to you and your father. Buying used parts is a great way to cut down on the financial burden of restoring a boat, and we’re huge fans of budget-minded boating over here at #Boatlife.

We wrote an article that would be of some big help when considering used boat parts. Here’s the link: https://www.hashtagboatlife.com/buy-boat-for-sale/

The article covers everything you need to know about buying used, what to look for in a boat and its parts, how to source things, and much more. Take a look and let us know if anything is missing or if you have any additional questions! We are always happy to help out where we can.

December 11, 2021 at 12:00 pm

I am a marine artisan and restore boats on a daily basis. I enjoyed this article, it provides a fair representation of the “hidden” or seldom thought of expenses. For example storage fee’s. Sometimes people have a niave, over simple impression of how much work and time is involved. The author did an excellent job touching on so many issues.

December 24, 2021 at 12:36 pm

Quality content is important to interest the viewers to visit the website, that’s what this site is providing.

August 8, 2022 at 8:56 pm

I appreciate all of the tips you provided for properly restoring a boat. I agree that it is smart to clean a boat thoroughly to help you spot problems you had not noticed before. It would also be smart to invest in quality marine paint so you can restore the appearance of your boat as well.

July 14, 2023 at 6:26 am

thank you so much for this cool post.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

MB #20512 PO BOX 480 Sevenoaks Kent TN13 9JY

Tel: +44 56 0386 9163

Keep In Touch

Thank you for reading.

Join our online crew and find more about the #boatlife

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Best Day on the Water

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

- ← Install & Repair

Fiberglass Repair

Advertisement

Few things are more disheartening to the boat owner than staring at the jagged edge of broken fiberglass. However, the repair-ability of fiberglass is one of its best characteristics. Even large holes in a fiberglass hull can be repaired with a bit of glass fabric, a supply of resin, and equal parts skill and care. And the repair is less patch than graft-a new piece of skin indistinguishable from the old. The best part is that a properly done repair can be as strong as (or stronger than) the original.

West System , which has been a leader in this field for many years, offers a huge amount of information online including detailed guides for many types of fiberglass work. Another good resource is found at MAS Epoxies and in particular, their how to videos. Following are some general tips. Your job may require very different steps and you should always carefully follow product instructions.

Cut Away the Damage

Never try to save damaged fiberglass; always cut it out and replace it with new laminate. Check all the edges and enlarge the hole if you find any additional delamination.

Use a disk sander loaded with a 36-grit disk to grind a 12-to-1 bevel around the perimeter of the hole inside. Also grind an area of the inner surface a few inches beyond the bevel to accommodate a finishing layer of cloth.

Mask and Mold

Mask off the area around the exterior of the hole and tape heavy paper or plastic below the hole to prevent resin runs from adhering to the surface.

Cut the first piece of fiberglass matt to fit the hole with a substantial overlap over the edge. Cut the next piece the size of the hole, and the succeeding pieces larger and larger to build the laminate up and out to fit the leveled edge. You may have to allow the first layers to set a little and stiffen before applying additional layers. Unless you have reason to follow a different schedule, begin with two layers of 1 1/2-ounce mat, then alternate mat and 6-ounce cloth.

Using Polyester or Vinylester Resin

For above-the-waterline repairs you can use either polyester or vinylester resin. Polyester is less expensive than vinylester and readily available but is more susceptible to osmosis, even above the waterline. Of course, for an even stronger repair you can also use epoxy, but if the surface of the repair will be gelcoat you'll have to spend more time preparing, sanding and dewaxing the resin to achieve adherence.

The catalyst for both polyester and vinylester resin is methyl ethyl ketone peroxide, or MEKP. Do not confuse MEKP with the common solvent MEK; they are not the same.

Gelcoat is essentially pigmented resin. It both protects the fiberglass underneath but primarily provides a cosmetic covering. This is a point where you must very carefully follow product instructions.

For a finished look, cut a rectangular piece of mat and one slightly larger of cloth and apply these over the patch, smoothing them with a squeegee. Seal this top layer with plastic or PVA to allow a full cure. Remove the backer from the exterior surface. Fill imperfections in the new gelcoat with gelcoat paste and allow it to cure fully. Clean the area around the patch, then sand — if necessary — and polish the repair area.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

BoatUS Editors

Contributor, BoatUS Magazine

Award-winning BoatUS Magazine is the official publication of Boat Owners Association of The United States. The magazine provides boating skills, DIY maintenance, safety, news and more from top experts.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

- (678) 322-7877

- 9605 Jot Em Down Rd. Gainesville, GA 30506.

How to Repair Boat Fiberglass

Did you know you can repair holes in the hull or deck of your fiberglass boat? To make these strong and to near cosmetic perfection, visit a shop that specializes in boat fiberglass and gelcoat repair. A DIY enthusiast can also achieve good results with fiberglass and gelcoat repair. Learn the techniques and materials that are used to get the best results.

A hole in the side of this Boat was permanently repaired to cosmetic perfection by choosing the right fiberglass materials and applying the proper repair techniques.

What is Fiberglass and What Gives Fiberglass Strength?

Fiberglass is from two components: resin and fiber. It is called fiberglass because the structural fiber used is actually woven with tiny flexible strands of glass. The fiber is then saturated with resin, stretched into place, and when it cures through a chemical reaction, the result is a hard and durable material. The strength of the fiberglass largely depends on the weight of the structural fabric that is used. There are different weave patterns to the fabric that render it useful for different applications. The resin component is either polyester resin or epoxy resin. Epoxy resin is stronger. If the repair area is large and is in a high-stress part of a boat below the waterline, epoxy resin is the superior choice. This is because it has excellent bonding properties to an existing surface and is strong. Polyester resin is commonly used. However, one drawback is that it shrinks as it cures and thereby diminishes its adhesive qualities. This shrinkage is insignificant in small repairs, even in high-stress areas. But because of the shrinkage and reduced adhesion, there are limitations to using polyester resin for large repairs in high-stress areas. However, outside of large structural repairs, polyester resin is the material of choice and is used in the bulk of fiberglass repairs.

For small fiberglass repairs, polyester resin is used in combination with mat or chopped cloth mixed in resin to make a sturdy repair.

Fiber Choices For Fiberglass Repair

The most common type of fabric is plain weave cloth. It is easily recognized as it is woven at 90 degrees, and it looks like cloth. It comes in different weights, and a thicker cloth is stronger. One limitation of plain weave cloth is that it doesn’t conform to complex shapes or curves. It’s best applied on an even plane. For complex shapes and compound curves that require strength, the best fabric is modified twill. Its weave appears to be diagonal, but in reality, it is also woven at 90 degrees and is a looser weave with flexibility. It can conform to complex shapes without wrinkling. The most flexible fabric is called a mat. It has hair-like strands going in every direction. Mat is bonded with glue that dissolves in polyester resin, enabling it to conform easily to complex shapes or compound curves. However, it has less strength and is often used in cosmetic applications unless built up in many layers. Lastly is a fabric called roving. This is a fabric that has course bundles of strands in its weave. It is a very heavy fabric for the strongest of applications. It will be used in combination with layers of mat to give a smooth final surface.

Structural fiberglass cloth and cosmetic mat are used in combination with resin to make a strong fiberglass repair.

Repairing a Hole With Fiberglass

When repairing a hole with fiberglass, repairs are best made by access from both the inside and the outside of the repair. However, access from the interior may not always be possible because a floor or interior wall may block access. If it’s a serious structural repair in a high-stress area, you’ll have little choice but to cut a hole through the floor or wall to access the inside of the repair. However, doing a repair from the outside only is possible for small repairs or repairs in low-stress areas. The first thing to do is assess the damage carefully by cleaning the exterior with acetone. This will make hairline cracks evident, and you’ll want to grind all the way back until the crack terminates. First, using a 4-inch grinder with 80-grit sandpaper, grind or cut away any broken material in the perimeter of the hole that lacks structural integrity. Then with the grinder, taper the edges of the hole using a 12:1 rule. That is, taper back the edge of the hole at an angle that is 12 times the overall thickness of the fiberglass material.

Checkout marine product sales online for all your boat repair equipment.

To repair a hole, use a 4-inch grinder and coarse sandpaper to grind away any broken material that lacks integrity. Then taper back the edges of the hole.

If it’s a repair from both the inside and outside, the taper will be centered on the thickness of the fiberglass and taper back on both inside and outside, resembling the cutting edge of an ax. If the repair is done from the exterior only, then the taper will start at the bottom of the thickness of fiberglass and taper toward the outside, resembling the cutting edge of a carpenter’s chisel. Next, after the taper from the edge of the hole outward is complete, grind back toward the perimeter to where the hairline cracks ended. Now the entire repair area has been defined. Repeat the same on the inside of the repair if you’re doing a two-sided repair. Clean all surfaces with acetone to be free of dust so the resin will adhere.

For a two-sided repair, next, you’ll cut a piece of fabric that extends to the outer margin of the repair. Mix up resin and hardener, and on a scrap piece of cardboard, lay your piece of fabric, and use a brush to saturate the cloth with resin. Turn the fabric over and coat the other side. Next, take the brush and apply resin to the interior repair area. Then carefully stretch the resin-soaked fabric over the hole, so it’s on a smooth plane and wrinkle-free. Use the brush to press out any air pockets, so the patch sits flat against the existing interior surface. Once the interior fiberglass patch has been set up and is somewhat hard, have already cut a piece of cloth or several layered pieces of cloth that will fill the thickness of fiberglass to near the surface plane of the exterior. The outermost layers will be a resin-soaked mat, so it will be smooth and not show the texture of the cloth.

Let the patch dry. Once it is dry, grind down the high spots with 80-grit sandpaper until it is on the plane with the finished surface. At this point, clean off the sanded area, and assess the low spots. If there are still high spots, continue to grind them down. Next, you’ll use a resin that’s mixed with chopped strands of fiberglass. This is a cosmetic layer, as the structural layers are already in place. This will fill the low spots and bring the repair up to plane with the exterior surface. Once the chopped strand layer is set up and hard, grind down the high spots until in plane with the finished surface. The next step is to mix up what is referred to as “peanut butter .”This is resin and thickener and is the consistency of smooth peanut butter. Using a plastic applicator, apply the peanut butter resin mixture to give the final surface all the way to the perimeter of the repair. If it is a curved surface, use a metal, plastic, or plywood flex board to smooth the final contour. Once this layer is dry, grind it down so you’re perfectly on the plane with the exterior surface. Now there should only be some minor pits and pinholes to fill. Use a skim coat resin and hardener and apply using a plastic applicator. Once dry, sand to perfection using fine sandpaper.

Spray the Gelcoat

The Gelcoat is the shiny hard finish surface on the boat exterior. Once the color is matched, spray on the finish coats of gelcoat. Once the topcoat dries, use 600-grit wet sandpaper and higher to seamlessly blend the new gelcoat with the original finish. Lastly, use wax to give the final buff to make the repair invisible.

Gelcoat is the shiny cosmetic finish to Fiberglass repair. It is sprayed on and built up in multiple applications to create a glossy topcoat.

Repairing a Minor Chip or Gouge in the Gelcoat

In this case, the structural fiberglass has no damage, and it’s just the finish layer of gelcoat that needs repair. Grind the repair with a Dremel tool to expose clean fiberglass and bevel back the repair edge. Mix up the correct color of gelcoat with hardener, and take a small brush and create a slightly raised puddle of gelcoat that entirely fills the void and extends just past the margins of the repair area. Let the puddle dry hard, then using 600-grit wet sandpaper, sand until flush with the finished surface. On a flat surface, use a sanding block to create a perfect plane. End with a coat of wax to make the repair blend in perfectly.

Repairing fiberglass is a multi-step process. However, even the most unsightly damage from hitting a rock, bumping into a dock, or even a collision can be repaired to look just like new. Lakeside Marine offers professional boat fiberglass repair from minor dings to major structural repairs. We also handle fiberglass repairs for boat insurance claims, making the repair and insurance reimbursement process seamless. We even do boat modifications and restorations.

Lakeside Marine does fiberglass repairs for boat accident insurance claims, classic boat restorations, and custom high-performance boat modifications.

For professional results for your boat fiberglass repairs, call email [email protected] or go to our webpage and learn about our [fiberglass repair services], and read customer testimonials about how Lakeside Marine performed outstanding fiberglass repair while providing exemplary customer service.

Book a Boat Fiberglass and Gelcoat Repair

NEVER MISS A POST

Sign up for free and be the first to get notified about updates

Pre Winterization Maintenance Tips

Oct 27, 2022

Your boat served you well over the past boating season. However, with normal wear and tear, your boat requires attention. Maintain your boat as service needs arise, and keep its value and performance at its peak. Reasons to perform boat maintenance in the fall and...

Boat Fire Prevention and What to do in case of Fire

Aug 2, 2022

Boat fires are serious, and here’s how to maximize your safety. We discuss the common causes of boat fires, how to prevent them, and what action to take if a boat fire breaks out. What are the common causes of Boat Fires? Electrical fires Explosive gas or propane...

Why is Boat Bottom Painting Necessary?

Dec 27, 2021

Boat bottom painting is necessary for any boat that stays in the water continuously for long periods. Bottom paint, also called anti-fouling paint, deters the growth of aquatic organisms, plants, and algae that damage your boat’s hull, affect the boat’s performance,...

Submit a Comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Submit Comment

Fiberglass Boat Repair Techniques: Quick and Effective Fixes

Understanding Fiberglass Boat Repair

With 20 years of boating experience , I’ve learned that maintaining the integrity of a fiberglass boat is essential. The repair process involves several crucial steps which require attention to detail and a systematic approach.

Firstly, assessing the damage is critical. Fiberglass boats can suffer from a range of issues, from minor scratches to major holes. As someone who’s handled many such repairs, identifying the extent of the damage dictates the repair strategy.

Here are the basic steps I follow:

- Inspect the affected area carefully to understand the depth and extent of the damage.

- Prepare the repair site by cleaning the area and removing any damaged or loose material.

- Sand the damaged area to create a rough surface for better adhesion of repair materials.

Next, selecting the materials is just as important as the repair technique itself. Epoxy resin is my go-to due to its strong adhesion and long-lasting repair qualities. Here’s a guide on basics of selecting repair materials .

Applying the repair materials involves layering fiberglass cloth and resin. The fiberglass cloth provides strength, while the resin, when cured, restores the integrity of the hull.

Remember, practice makes perfect. Working with fiberglass can be daunting, but with patience and care , a meticulously completed repair is indistinguishable from the original structure. Each repair I’ve completed over the years has reinforced my precision and skill, ensuring lasting results that keep my vessel seaworthy.

Materials and Tools Required

In my 20 years of boating experience, I’ve found that having the correct materials and tools is crucial for a successful and durable fiberglass boat repair. Knowing what to use will save you time and ensure the integrity of your boat’s structure.

Essential Materials

- Fiberglass Cloth: A foundational element for any repair, providing strength and stability to the damaged area. The quality of the cloth directly affects the repair’s resilience.

- Resin (Epoxy or Vinyl Ester): Acts as a binder for the fiberglass cloth. Epoxy resin is preferable for its strong bond and water resistance.

- Gelcoat: For aesthetic touches and to protect the repair from UV rays and water intrusion, gelcoat is applied as the outermost layer.

Recommended Tools

- Sandpaper (Various Grits): Starting with coarser grits for shaping and finer grits for finishing provides a smooth surface for repair.

- Acetone: Essential for cleaning the repair area and ensuring that contaminants do not compromise the bond.

- Brushes and Rollers: For applying resin evenly. Brushes are used for detail work and rollers for larger areas.

- Mixing Sticks and Cups: Necessary for preparing and mixing the resin before application. Accurate measurements are key to achieving the desired cure and bond strength.

Assessing the Damage

In my 20 years of boating experience, I’ve come to understand that thoroughly evaluating the type and extent of damage is critical before undertaking any repair work on a fiberglass boat.

Types of Damage

Structural Damage: This occurs to the supporting framework and influences the boat’s overall integrity. A cracked hull, for instance, compromises the vessel’s safety and needs immediate attention.

Cosmetic Damage: These are surface-level issues, such as gelcoat cracks and scratches, that do not affect the boat’s seaworthiness, but restoring the appearance is important for maintaining value.

Damage Assessment Process

Visual Inspection:

- Examine the hull and deck for any obvious signs of impact or wear.

- Look for hairline cracks, which could indicate more severe damage beneath the surface.

Tap Testing:

- Gently tap the fiberglass with a plastic hammer.

- An area that sounds hollow or different could be suffering from delamination or water intrusion.

Moisture Readings:

- Use a moisture meter to detect any water retention within the fiberglass.

- Higher readings signify potential problems with the laminate that could lead to further deterioration.

Assessing the damage with precision sets the stage for an effective and necessary repair. While smaller repairs may be DIY-friendly, significant structural damage often requires professional intervention.

Preparing for Repair

With 20 years of boating experience, I’ve learned that successful fiberglass boat repair starts with meticulous preparation. Whether you’re patching a small chip or mending a larger gash, setting the stage correctly is crucial for a long-lasting fix.

Surface Preparation

Before any resin or gelcoat is applied, the area must be clean and properly prepped. First , the damaged spot should be sanded down to remove any jagged edges and create a receptive surface for bonding. Then , washing the area with a dewaxing solvent is essential to eliminate any wax or mold release, which could compromise the repair. I’ve found that skipping this step can result in weak adhesion of the new material. Visit Repairing Fiberglass On Boats for a comprehensive guide on working with fiberglass.

Safety Measures

Fiberglass repair requires handling hazardous materials, so safety cannot be taken lightly. Always wear:

- Gloves : to protect your hands from sharp fiberglass strands and chemicals.

- Respirator mask : to avoid inhaling hazardous dust and fumes.

- Safety goggles : to shield your eyes from debris.

Moreover, maintaining a well-ventilated workspace is non-negotiable to dissipate fumes from resins and solvents. This minimizes the risk of respiratory issues and ensures a safer working environment.

Fiberglass Repair Techniques

With 20 years of hands-on boating experience, I’ve developed a deep understanding of fiberglass repair techniques that are essential for sustaining the integrity and appearance of your vessel. The key to successful repair lies in identifying the scale of the damage and employing the correct method.

Minor Repairs

Minor damages to a fiberglass boat, such as small scratches or chips, can often be repaired with simple DIY solutions.

- Materials Needed : For such repairs, you’ll need resin, hardener, fiberglass cloth, sandpaper, and a suitable gelcoat.

- Process : Begin by cleaning the area thoroughly and sanding down any rough edges. Cut the fiberglass cloth to size, mix the resin with hardener, and apply it to the affected area. Once the resin cures, sand it down to a smooth finish and apply the gelcoat for aesthetic appeal.

To illustrate, fixing a hairline crack would typically involve cleaning the area, applying a mixed resin, and laying down a piece of fiberglass cloth. After the resin has cured, I’d sand the area flush and then apply a gelcoat to match the boat’s original finish.

Major Repairs

For more significant damage, such as holes or structural weaknesses, the repair process is more complex and may require professional intervention. However, I’ve tackled such challenges myself when possible.

- Materials Needed : A list of materials includes thicker fiberglass matting or cloth, epoxy resin, a release agent, and reinforcing materials.

- Process : The area in need of repair must be ground away to remove any damaged material and to create a beveled edge where new material can be applied. Next, layers of fiberglass and resin are built up until they fill the area. It’s critical to ensure no air pockets are trapped, as this could compromise the repair’s integrity.

For example, repairing a hole in the hull involves placing a backing material behind the hole, then layering fiberglass and resin until the repair is level with the hull surface, finishing with sanding and gelcoat application. Each layer must cure properly before the next is applied, ensuring a bond as strong as the original hull.

By applying these techniques, I’ve been able to extend the lifespan of boats and maintain their value and performance.

Finishing the Repair

In my 20 years of boating experience, I’ve learned that achieving a flawless finish on a fiberglass repair is crucial for both aesthetics and the boat’s integrity. Accurate sanding, followed by meticulous buffing and polishing, are the final steps to ensure a repair blends seamlessly with the boat’s original surface.

First Pass: Coarse Grit. I start with a coarse-grit sandpaper to remove the excess cured fiberglass, working my way towards the repair margins. Care is taken not to gouge the surrounding area, which could require additional repairs.

Second Pass: Medium Grit. Once the high points are leveled, I switch to a medium-grit sandpaper. Gradual transitions are essential to avoid noticeable edges or low spots in the final product.

Final Pass: Fine Grit. To prepare for finishing, I use fine-grit sandpaper. This smoothens the surface further, removing any scratches left by coarser grains and creating a surface ready for polish.

Buffing and Polishing

Buffing Stage. After sanding, I buff the area with a rubbing compound to remove any fine scratches. This process requires a gentle touch and a steady circular motion to achieve a uniform shine without creating swirl marks.

Polishing Stage. The final step is applying a high-quality marine polish. This not only enhances the shine but also adds a protective layer against UV rays and saltwater. For the best results, I apply polish in thin layers, allowing each to dry before buffing it to a high gloss.

Gelcoat Application

In my 20 years of experience with fiberglass boats, I’ve learned that the key to a superior gelcoat finish lies in meticulous mixing and precise application methods. Ensuring the mix is correct and the application is smooth will greatly affect the longevity and appearance of the boat’s surface.

Gelcoat Mixing

Before applying gelcoat, it’s crucial to prepare the mix accurately. I always start with a clean mixing container to avoid contamination. Then, I add the gelcoat base, followed by a catalyst—typically methyl ethyl ketone peroxide (MEKP)—at a precise ratio, which is often around 2% of the volume of the gelcoat. Mix thoroughly for at least 2 minutes, ensuring a uniform color and consistency with no streaks.

Gelcoat Application Methods

When applying gelcoat, I use two main methods: brushing and spraying. Each has specific advantages, so I choose based on the repair’s nature and size.

- Ideal for small repairs or areas that are not easily accessible.

- Use a high-quality brush for an even coat and to avoid brush marks.

- Preferred for larger areas to achieve a more consistent finish.

- Requires a gelcoat spray gun and personal protective equipment to prevent inhalation of fumes.

Regardless of the method, it’s important to maintain a wet edge to avoid visible lines in the finish and apply multiple thin layers rather than one thick one to reduce the likelihood of sagging or running. After application, curing times can vary, but I usually wait a minimum of 24 hours before sanding or polishing.

Curing and Post-Cure Procedures

With two decades of handling boats, I’ve learned that meticulous attention during the curing and post-cure phases is critical for dependable fiberglass repair.

Curing Process

The curing process is when the resin hardens and bonds with the existing fiberglass. I ensure that the temperature is between 70-80 degrees Fahrenheit, as too cold or too hot can affect the cure. When I apply resin, I layer it with a catalyst, make sure the area is well-ventilated, and keep it free from dust. I use plastic film or PVA as a seal over the last resin layer to ensure a thorough cure without any tackiness.

Post-Cure Inspection

Once the resin has fully cured, my next step is a thorough inspection. I feel for imperfections such as bumps or air pockets. Any found imperfections are then addressed with gelcoat paste and allowed to cure fully. After it has cured, the patch should be sanded smoothly and polished to match the surrounding area, restoring the boat to its original condition.

Maintenance Tips

With my 20 years of boating experience, I’ve learned that regular upkeep and a proactive approach to maintenance can save you from costly repairs in the long run. Let’s dive into what I consider essential practices.

Routine Maintenance

Inspect and Clean: Every time I return from the water, I make it a practice to inspect my boat thoroughly for any signs of damage or wear, especially on the hull. I pay close attention to scratches or cracks that can worsen over time. After inspection, a thorough cleaning with soap and water helps identify any new issues that may have been obscured by dirt or debris.

- Simple Repairs: For minor scrapes that haven’t penetrated the gelcoat, I apply a marine polish to protect the area. It’s a simple but effective method to maintain the integrity of the fiberglass. However, if the damage is deeper, I make sure to apply a patch at the earliest opportunity to prevent water infiltration.

Preventive Measures

Regular Waxing: I ensure that twice a year, my boat receives a good layer of quality marine wax. This acts as a barrier against UV rays, salt, and pollutants that may harm the fiberglass. It’s an effective way to extend the boat’s aesthetic appeal and structural integrity.

- Storage and Cover: When not in use, I store my boat in a dry and shaded area. A sturdy cover is essential to protect it from the elements. I’ve learned that proactive covering minimizes the exposure to sun, moisture, and temperature fluctuations that can lead to fiberglass degradation.

Remember, a well-maintained boat ensures not just longevity but also safety and reliability. It pays to adopt a meticulous care routine.

Frequently Asked Questions

Drawing from my 20 years of boating experience, I’ve compiled a list of frequently asked questions relevant to fellow boaters looking to repair their fiberglass vessels. These inquiries cover the essentials of materials, procedures, and costs involved in keeping your boat seaworthy.

What type of epoxy is best for repairing boat hulls?

In my experience, marine-grade epoxy is the most reliable for repairing boat hulls due to its strong adhesion, resilience to water, and ability to bond with fiberglass. It’s crucial to select an epoxy that cures hard and can be sanded and painted over for a uniform finish.

What steps are involved in repairing large gelcoat damage on a boat?