DIY Cruising Catamaran: Complete Building Guide

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

A brand-new cruising catamaran can set you back a hefty amount of money. However, a DIY cruising catamaran provides a more affordable way to own your own boat. While building a large boat can be an extremely challenging and time-consuming experience, nothing beats the pleasure of bringing your own boat to life.

To build a DIY cruising catamaran, buy good design plans, determine your budget and find a working space. Next, choose your hull material, buy supplies and start building the mast beam. Build and sheathe the hull, install bulkheads, the interior, and finally, launch the catamaran boat.

In this article, you will find a complete guide to building your own catamaran. You will also find detailed information on why you may want to consider building your catamaran and approximately how much this project would cost. Finally, we will explore the advantages and disadvantages of building a catamaran from scratch.

Why You Might Want To Build Your Own Catamaran

Most people might think that purchasing a used boat to repair and fix it up would be cheaper than a DIY cruising catamaran. But while building your own catamaran could be an enormous undertaking, it also comes with many advantages over buying something used.

Other than the unique opportunity to create beautiful memories and experiences while cruising, sailing, and exploring beautiful coastlines, there are a number of benefits that come along with the DIY approach.

Knowing Your Boat

Building your own catamaran provides you with intimate knowledge of your boat. You will know every corner, including where to find every bolt, wire, bulkhead, rib, hose, and support as you installed them yourself. This knowledge will enhance your confidence while at sea since you will have entrusted your life to a boat whose history you are aware of and deeply connected to.

Pride of Ownership

The satisfaction you get from crafting something with your own hands is immense. As a result, the knowledge that you built your boat from scratch will fill you with absolute pride and an immense sense of achievement. Furthermore, as an owner-builder, you get to keep and enjoy the boat for as many years as you wish.

Substantial Cost Savings

Building your catamaran will work out cheaper than buying a new or even gently used boat. Though you will likely require some additional labor since doing some things will require an extra pair of hands, if you are particularly good at DIY, you will save a significant amount of money on labor costs as a whole.

Freedom To Create Your Own Designs

If you decide to buy a catamaran boat, it might not be easy to find one that meets your unique needs. However, instead of choosing from production boats that bear traditional and outdated designs, you can come up with an ultra-modern design or style for your catamaran. You also get to pick your layout, size, and equipment based on your taste and budget.

Great Learning Experience

Building your own boat will help you pick up numerous skills that will come in handy later when sailing your boat. As much as you might still require an expert to help you with specialized skills like carpentry or wiring, your new skills will serve you well. This will also be beneficial when it comes to your boat’s maintenance and fixing things for yourself.

What To Look For in Catamaran Boat Designs

When deciding on the type of catamaran boat to build, you may want to choose a design that’s simple and easy to build. This is because doing so will allow you to spend a shorter time building the boat.

You also need to have a set of requirements to guide you in choosing your design or what you might call an ideal cruising catamaran wish list. This is essential because, ultimately, you want to build a boat that offers outstanding qualities such as:

- Delivers good speed

- Affordable to own and operate

- Agile, strong, and easy to maintain

- Has a high resistance to capsizing

- Great for sailing and cruising

- Delivers a comfortable and easy motion underway

- Good handling ability and high performance under sail

- User-friendly embarking and disembarking

- Provides ample living and accommodation space

- Presents a reasonable resale value

It’s worth noting that, in general, catamaran boats tend to offer a fair resale value mainly because of scarcity and the high price accorded to production models. So, if you build a well-constructed catamaran, you are bound to get a return that’s much higher than the cost of materials upon resale.

It’s also good to consider whether the design you settle on is from an established designer. This is significant because documentation of the building process is just as valuable when it comes to selling the boat.

How Much Would It Cost To Build Your Own Catamaran?

The cost of building your cruising catamaran will depend heavily on the size of the boat you plan to build and the skills you bring to the table. To give you an idea of probable costs, a professionally built 40 foot (12.1 m) long cruising catamaran could go for up to $300,000.

Though building it yourself will undoubtedly be cheaper, most DIY boatbuilders tend to underestimate the expected costs. Your final costs should cover not only the cost of material and equipment but also the labor and time it would take to come up with the final product.

If you were to build a 40-foot (12.1-meter) catamaran, your cost of materials would range between 20-30% of the total cost. Therefore, for $300,000 total, the boat’s materials would range between $60,000 and $90,000. The hull tends to range between 15-35% of the total build. Again, this depends on the finish and furniture.

But before you even start working on the DIY project, you will need to figure out where to do the work. If your home has ample space, then you can opt for a backyard building. But if you live in a small apartment, then you might want to consider renting a small garage at first and then move on to a boatyard later. This is one of the significant costs involved in building your multi-haul.

What You Will Need

To get a clearer picture of how much the entire project would cost, let’s have a look at what else you will need to purchase.

- Good design plans

- Working space

- Ground tackle

- Matting and roving

- Equipment such as the engine, windows, rudders, deck fittings, mast, and rigging

In addition to the above, you also need to install plumbing and electricals. You may also want to consider going electric rather than using diesel. Not only will this drastically reduce your maintenance costs, but you get to use the regenerated power for all of your housing needs while sailing.

Some catamaran boat designs help you save costs by advocating the use of less expensive corpus materials. Most of the material goes directly into making the boat, which means there is hardly any wastage on vacuum bagging . With this method, there are few molds and temporal building forms and fewer fillers to grind off as waste. All these factors reduce the time and cost it takes to build your catamaran boat.

That said, building a boat of any kind is a huge financial undertaking. As such, you still need to have the financial ability to keep building; otherwise, your project will stall or take much longer than anticipated. Instead of enjoying yourself and making memories cruising to faraway lands, you might end up spending all your time building a seemingly never-ending boat.

To reiterate, this project is more of a labor of love, given that it involves a tremendous amount of manual work. Calculating an hourly rate on the time spent building the boat and adding this cost to that of materials may make it seem a very pricey exercise. However, it is vital to understand that your time matters, and every hour you spend working for “free” should be included.

With that in mind, you need to ensure that you are fully devoted to the boat construction project and are sure you want to do it before you begin. Stopping halfway because it seems like too much work would be incredibly costly.

How To Build a Catamaran

When it comes to building a cruising catamaran, you have 3 main options:

- You can buy an old boat and refurbish it.

- Purchase a bare hull plus deck molding for a home-boat building.

- Start from scratch and build everything, including the hull, on your own.

As mentioned above, renovating an existing boat may end up being more costly than starting from scratch. To build a catamaran boat from scratch, follow the below step-by-step guide.

Prepare the Essentials

Before you jump into such a large project, there are several important aspects to consider:

- Buy your plans from an established catamaran designer. You can also get inexpensive, easy-to-build catamaran designs online.

- Get access to a large working space or build a shed . Depending on your climate, you may need to opt for climate control to avoid an excess of moisture in humid areas.

- Decide on your choice of hull material. This could be fiberglass, aluminum, steel, wood, or ferroconcrete.

- Start working on a bill of materials estimate. Include everything that you think you need to get a better idea of the initial costs.

Build the Mast Beam

Using wood and epoxy, cut and glue together the pieces of wood that will form the mast beam. Most of the work at this stage can occur in a garage since it involves building small parts. Still, the work could take up to 4 months, so be prepared to put in long hours.

Build the Boat Hull

Now, it’s time to build the boat’s hull. A catamaran comprises two hulls which are connected with a deck. Below is a short video showing how to build a hull mold:

This work requires a larger facility, so you might need to move out of the garage and into a boatyard. If you don’t have access to a larger workshop, consider building a shed where you can work as you do the construction. Make sure there’s enough room to fit the boat and also allow you to work comfortably. To cover the shed, you can use opaque white tarps.

Sheathe the Hull

Get all the materials you require for this stage in the construction, such as lots of resin, fiberglass, and foam for use in the hull cores. You’ll also require matting and glass roving to sheath the hull .

Sheathing helps to make the hull impervious to water and other marine borers. But first, you need to prepare the hull using a rotary sander. To make it as smooth as possible, use light, sweeping strokes. This is a very dusty task so be prepared to wear a facemask and safety goggles.

Install the Bulkheads

Next is installing the plywood bulkheads . You might need to call in friends to help turn the hulls or use a crane. In this step, you will need to laminate the hull sides on the molded hull panels and bond them above the bulkheads. Ensure the bulkheads are snug and sealed in place.

Construct the Interior Structure

Over the next couple of months, the boat work will involve joining the hulls together with the beams that you had made back in the garage. Then, install the cuddy cabin, decks , and the cockpit . Soon the boat will start to take the shape of a catamaran.

Next, proceed to construct the major structural components such as stairs, hatches, mini-keels, and the interior. Then comes the work of fairing the boat, which is quite labor-intensive.

Finally, it’s time to apply primer on the catamaran boat and start the paintwork. Before painting the boat, you will need to do additional sanding to finish off the two layers of primer as well as fill all the pinholes. Since it’s a large boat, the catamaran has lots of surface area; thus, the sanding could get extremely exhausting—mentally and physically—at this point.

The painting can take a while, too. The hulls are the easiest to paint, but the topsides, non-skid, as well as masking and prepping could seem never-ending.

The final stretch involves working on the center bridge deck cabin and other final touches like installing the engines, electricals, and plumbing. This is also the time to fix the rudders, rigging, mast, windows, and deck fittings.

Launch Your Cruising Catamaran

After many months or years of hard work, your cruising catamaran is finally ready to test the waters. After lowering the boat into the water, check carefully in case there are leaks. If none, you can set up the sails and take your catamaran out for your first cruise.

Below is a short video that takes you through the entire boat-building process:

If you don’t have deep pockets, don’t despair. It’s also possible to build an inexpensive catamaran boat, as shown in this post from the coastal passage .

The Pros of Building a Catamaran

Though it will be a costly endeavor, there are so many things to look forward to should you decide to build your own catamaran:

- It can be lots of fun.

- You get to have a new boat.

- It’s an excellent hobby for DIY enthusiasts.

- The effort is rewarding.

- It offers a great learning experience.

- You get the exact kind of boat you want.

- You can alter building plans and tailor the boat to suit your specific needs.

- It might be cheaper than buying a new boat.

The Cons of Building a Catamaran

Though there are a number of positive aspects to a DIY build, it is just as important to keep in mind that it won’t always be easy:

- Maintenance costs can be quite high.

- It’s both mentally and physically exhausting.

- It might require some technical know-how.

- It can take many months or even years to complete.

- It requires a lot of commitment to finish the DIY project.

- It might be challenging as well as expensive to get insurance.

- You will spend almost all your free time building the boat.

DIY Cruising Catamaran Tips and Tricks

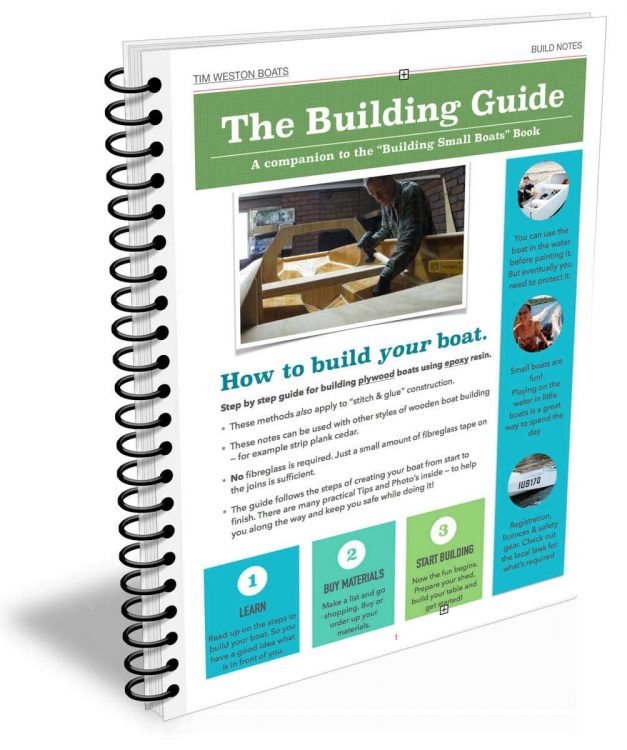

If you are new to boat building, it would be a good idea to build a small boat first. This would give you a good indication as to whether you’d enjoy tackling a more extensive project like building a catamaran. Again, if you are the handy type, fixing your own electronics could also save you a significant amount of money.

Here are more tips and tricks to get the most out of your DIY cruising catamaran:

- Lower your costs. Bring down your costs even further by sourcing for parts and supplies at marine surplus outlets, Craigslist, eBay, or wholesale suppliers.

- Enhance your resale value. Most home-built boats are not easy to sell since they tend to be too customized. To enhance your resale value, it’s advisable to work with a standard design from a well-established naval architect.

- Follow the design instructions. Make sure to follow the designer’s instructions regarding the type of materials and tools to use during the build to avoid making costly mistakes.

- Maintain your original budget. Avoid any additional customizations once you have started building the boat. Using good plans and sticking to them ensures that your budget doesn’t spiral out of control.

Final Thoughts

Building a catamaran is about more than saving money. It’s fun, exciting, fulfilling, and can be a great learning experience. While it might take many months of back-breaking work, comparative shopping and sourcing for materials will help you save a lot of money. Still, at the end of it all, you’ll have a beautiful catamaran boat, all ready for your first cruising adventure.

However, if you have neither the time nor the energy to build your own catamaran from scratch, refurbishing an existing hull might prove faster and easier. It also works out much cheaper than buying a new boat.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

One thought on “ DIY Cruising Catamaran: Complete Building Guide ”

Hello, I am a French Quebecer who is original, imaginative, creative and who finds that all boats and catamarans have a huge flaw and a very big lack of logic. I would have a brand new concept…. I am sending this message to any catamaran creator – designer to make those who have the opportunity and the intelligence to want to know about my innovative idea which will finally upset the market much richer. An idea that will totally change the concept of sailing, navigation and save so much worry!! All I would ask for is a small percentage of each sale of the new product. To be able to make me produce one when I have enough!! It is certain that like that, you just want to tell me: come on Mr. Lessard give us your idea but do not take your word to help me in return! But, if you are the kind of man to have only one word and maybe have a proof of your good faith if the realization of the project would make it… I will be very happy!! Giving it to everyone wouldn’t bother me either…. all I would like is to be able to find flax fiber (too expensive carbon) to be able to try to make my catamaran myself. Because not rich! Have a nice day and looking forward to having a message!!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

Matt & Jessica's Sailing Page

Experiencing the world while it's still large

What is it Going to COST to BUILD a Kit CATAMARAN? – A Comprehensive Guide (MJ Sailing)

The big question on everyone’s mind is … what is it going to COST us to build this new catamaran?

Matt has spent the past few weeks talking to the designers at Schionning and Oram, as well as professional and ameture builders to gather as much information as possible on the costs that go into building a kit catamaran. Things can obviously vary from builder to builder, but taking a simple and basic approach, we’ve narrowed down the numbers on what we estimate it will cost to build an Oram 45R.

To take a look at the full design specs, take a look here: https://www.boboramdesign.com/45r

For a quick look at the numbers, check our website: https://www.mjsailing.com/cos/oram-45r…

For a download of the spreadsheet, click here: https://www.mjsailing.com/wp-content/u…

After discussing previous builds with the many others who’ve come before us, we found out there is one small thing that can skyrocket a budget – and that is making customizations after you’ve started the build. But, if you start with good plans and commit yourself to them, it is very feesable to stick to your original budget.

Sending the above spreadsheet to both designers and builders, and asking if they were realistic figures, they all came back stating that we’ve covered all aspects and should be able to complete the project within the budget we have listed. And that, is music to our ears!!

Since this is a very long video because we have tried to keep it as detailed as possible, here is an outline of subjects covered if you’d like to bounce through to the areas that interest you:

0:00:00 – Intro by Jessica 0:03:50 – Intro by Matt 0:15:32 – Intro To Budget 0:16:30 – Costs relating to Kit 0:21:45 – Total cost of Kit shipped to the US 0:24:23 – Costs relating to Building Supplies 0:32:10 – Total costs of Building Supplies 0:32:53 – Total cost of First Year of Build (getting to paint stage) 0:35:41 – Costs relating to Paint 0:39:05 – Costs relating to Sailing (rig, sails and deck hardware) 0:45:17 – Total costs of Sailing 45:38 – Costs relating to Engines 0:50:42 – Costs relating to Steering 0:52:32 – Costs relating to Electrical System 1:00:50 – Total costs of Electrical System 1:01:07 – Costs relating to Achor (anchor, chain/rope, windlass, docking gear) 1:04:05 – Costs relating to Lights 1:07:17 – Costs relating to Galley 1:12:07 – Costs relating to Exterior 1:16:53 – Costs relating to Interior 1:17:45 – Costs relating to Heads 1:19:12 – Costs relating to Electronics 1:22:20 – TOTAL COST OF BUILD 1:26:40 – Closing by Jessica

Much love from England! Jessica, Matt & Georgie

9 Responses

Hey again M&J

Just watched you cost vid, pretty much covered it all. Awesome. I had another thought for you on the kit, ask Bob (Oram) or Jeff (Schionning) if shipping is mandatory with their kits. What I mean is, both use west system epoxy mostly although our kit also included atl kinetics resin for under waterline wetout, nevertheless you may be able to source that (and the various powder additives) locally rather than pay international shipping on it, same goes with double bias and uni glass, which leaves the composite panels. I have heard that designers may sell you the rights (single use) to the CNC files but it very much depends on if they know and trust the composite panel makers. If they do there may be a company similar to ATL in the US to make you the panels. Just a thought based solely on the absurdity of West being made in the US, shipped to Australia only to be shipped back.

Great to hear from you! *anyone reading this- Paul built a beautiful Schionning cat and did the best documentation I’ve seen of the process at Yikes.com.au

Funny, the first suggestion I received from Oram was to get my epoxy in the US. Not only is it cheaper, but apparently Epoxy is a hazardous material and just the mess of importing it is best to be avoided. But we’ll probably source the fiberglass straight from ATL. Â In the US it’s more difficult than it should be to get the designer’s suggested cloth weave and weight. Our common weights are just different enough to cause some problems that I don’t want to have to reengineer for.

I did a cursory budget for building the panels myself, but unless my supplier’s bulk pricing was way too high, the ATL price vs infusing my own panels were surprisingly close – and it was even closer getting them from Schionning’s South African manufacturer. Buying 200 sheets of Divinycell still didn’t get me into the price point to make it worthwhile 🙂 But adding the savings along with not needing shipping and import does get to the point that we’d essentially be paying ourselves a fair wage to infuse them, but I keep thinking that all it takes is one bad hull length infusion and we’d be at a large loss. It would give us continuous panels without need joints, but the South African panels are 40′ long and only need one seam now… so hardly a big benefit there either. That debate still rages on 🙂

Get out there and use that awesome boat! I can’t believe it’s been sitting on the mooring for so long without you guys at least using it as a power boat.

Hey Matt, As I suspected there’s not much you don’t already know or scoped out. I hear you regarding infusion. I did a bit of research into the kss Kelsall process but in the end decided I perhaps don’t have quite enough skill or attention to detail to be confident in my ability to infuse a 40ft panel, the last thing you want is delamination. But the “out of a mold†with paint already on sure is attractive, if I was ever to build again, anything that reduces fairing is worth it’s weight in beer in my opinion. And yes, all going well we intend using Yikes later this year, if only around our home port but I have to get the ammenities and comfort up to spec to get Jo on board. Loved the Thai charter adventure vids. Cheers Paul

Great video. Thanks for compiling all this together. It’s compelling enough that I’m seriously considering actually going for it.

Couple of questions: 1. I’m trying to scout the building locations. I live in an apt so no access to a big backyard. I know you mentioned leasing a parking lot potentially .. do you have any pointers. Logistically that seems like a huge problem that I’m struggling to overcome given that leasing an industrial warehouse (if I can find one with the doors large enough) would be at least 20K per yer for the ~2000 sq feet I’d need. 2. Have you considered Spirited Designs (as in Sail Surf Roam). What is it that ultimately made you go the Oram route? Designs seem very similar between Schionning and Oram and even the layout seems similar. 3. Oram build hours estimate and the overall cost seems much lower than Schionning. Did you figure out why that is or am I misreading something.

Thanks in advance! Good luck with your new adventure!

Build location is something we’re still struggling with too. I’ve been limited to online searches and emailing agents (Craigslist is a good source) since we are still in the UK and unable to travel back to the US to personally scout out locations. But since we can build anywhere we want, we can pick the best climate for our build (epoxies have some environmental requirements) Where are you located?

It’s almost impossible to find a warehouse with large enough doors to get a cat out in one piece unless it’s an airplane hanger. The typical way most ‘home” builders do it is to remove the wall of the warehouse to pull the boat out… it’s not that hard or expensive to do on a steel building. You just have to find a landlord that is okay with you pulling off the siding/wall and taking a frame or two down for a few days.

The Spirited Designs is a great boat, but for us, it has a few minor traits that we are looking to avoid. Plus, the 38′ is smaller and the 48’ is bigger than we want… no happy medium is offered.

The ‘Cost’ video was just our breakdown for the Oram 45R… like the build video showed the Schionning. We haven’t decided on a design yet- the Oram, Schionning and Grainger are all still 100% in the running.

The Oram is a simpler boat to build. It has a single seam at the sheerline- Schionning is multiple panels that need to be taped and faired- and it doesn’t have the extra seam on deck (another set of panels less on the Oram), and even the cabin top has one less seam (and another panel set less). For better or worse, the stock interior plan is more basic on the Oram too. One simple thing that save a lot of time is the lack of secondary floor (sole) in the hulls. Down below you stand on the hull itself without an additional raised floor like on the other boats.

I haven’t seen Oram list a lower amount of time for the build than Schionning (Grainger does show higher hours). Bob’s site say 5500-7500 hours for the 45R, while Schionning’s site says 5,000 for the Arrow 1360 (design comparison PDF). Schionning shows cost as $260,000 AUD for the 1360 and Bob say’s from $205,500 AUD to $265,500+

And a final FYI- Grainger is doing some redesigns of the Raku- along with new pricing- and will have that information out in the next few days. From talking to Tony, it sounds like they are making a big push this year. Shoot him an email (graingerdesigns.net) and he’ll keep you in the loop with the new detail.

Matt Johnson MJSailing.com

Thanks for that response. I’m down in Miami. I like the year-round warmth for epoxy curing but not sure about the rain/humidity/hurricanes. I’m debating whether I should entrust someone like Ojigawan to build it in VA and just make the trips there as often as possible but that takes the fun/experience of building out of the equation, limits the learning, and last/not least raises the cost 🙂

I did get a quote for the Schionning Arrow 1360 out of Pantawee in Thailand — PM me if you’d like to know what that looks like. In my calculation it comes down to the hourly rate of about $29 which seems very high given that the generous wages in Thailand are about $5 per day.

Good to know about Grainger — will keep my eye out for those new designs.

Did you ask Julian at Current Marine in South Africa for a quote on the Schionning? They maybe a bit more competitive than the Thailand builder since they have so much experience with Schionning (they build the foam kits that Ojigawan uses). I think they also offer pretty good pricing on mast, hardware and all the other needed supplies in SA. Take a look at Current Marine’s CM45 too- it’s an awesome Schionning design.

Good tip. Will reach out to Julian.

By the way — made some progress with locations with some help from my realtor friend. You can find ~ 3k foot parking lots in the Miami area for about 1-1.5k per month. Not cheap but certainly an option. Typically they’re in the industrial areas which have some local laborers that can help with fairing, etc.

Another interesting data point is that some of the builders are estimating about 6500-7000 hours for the arrow 1360 build and trust that 5k hours gets you a very basic/rough boat.

BTW — did you see those new Graingers? pretty sweet! Apparently they have a promotion if you’re willing to purchase plans in the month of June — not sure the details.

The discount is 10% off for the month of June. If you talk to Grainger, tell him we sent you… we get a referral for each customer that acts as a discount for our kit 😉

We’ve found lots for around $500, but those are nowhere near populated areas like Miami. Besides the rain, humidity, heat and cold, one of my big fears with building in a lot is security. We can lock up to tools and supplies in the shipping container, but I’m really looking for a good fenced in area, but this has been a bit harder to find in our price range.

I think 7000 hours is a pretty accurate timeline for a novice builder. I’ve spoken to a guy that built a beautiful Arrow 1280s in 4,000 hours, but that seems to be exceptional and not at all average.

Add a Comment

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

How to Build a Catamaran Boat? (Step-by-Step Guide)

Building a catamaran boat from scratch is a rewarding and challenging endeavor.

It takes a combination of skill, dedication, and hard work to craft a seaworthy vessel.

In this step-by-step guide, you’ll learn how to design and size your catamaran, gather the necessary materials, cut and assemble the pieces, lay fiberglass and apply epoxy, make finishing touches, add hardware and paint, and rig the boat.

With the right tools, planning, and patience, you can make your dream of sailing in a catamaran a reality.

Table of Contents

Short Answer

Building a catamaran boat requires a lot of patience and skill.

The first step is to choose the right materials for the hull, such as fiberglass, wood or aluminum.

Then, you will need to build the frame of the boat, which includes the crossbeams and the main hull.

After that, you will need to install the decking, the rigging, and other components.

Finally, you will need to paint and varnish the boat, as well as install the outboard motor and other accessories.

Design & Size Considerations

When it comes to building a catamaran boat from scratch, the first step is to determine the design and size of the boat.

This should take into account the intended use of the boat, such as sailing, fishing, or leisurely cruising.

The size of the boat will depend on the number of passengers and the type of activities the boat will be used for.

For instance, a larger boat may be needed if passengers will be standing or participating in watersports.

The design of the boat is also important and should be chosen based on the intended use.

If you are looking to build a sailboat, you will need a design that is optimized for sailing.

On the other hand, if you are looking to build a fishing boat, you will need a design that is optimized for fishing.

There are a wide variety of boat designs available, so it is important to research and choose the one that best suits your needs.

In addition to the design and size, you will also need to consider the materials used for construction.

The most common materials for building a catamaran boat are wood, fiberglass, and epoxy.

Each material has its own advantages and disadvantages, so it is important to research them and determine which one is best for your project.

Finally, you will need to consider the cost of the project.

Building a catamaran boat from scratch can be a costly endeavor, so it is important to have a budget in mind before you begin.

The cost will depend on the type of materials used and the complexity of the design.

It is also important to factor in the cost of any tools that may be needed for the project.

By taking into account the design and size, materials, and cost of the project, you can be sure to build a catamaran boat that meets your needs and budget.

With the right amount of patience and attention to detail, you can build your own catamaran boat in no time.

Gathering Materials

Gathering the materials needed to build a catamaran boat from scratch can be a daunting task, but it is essential for creating a sturdy and safe vessel.

Before starting the building process, it is important to have an accurate and detailed plan for the boats design and size.

Once a plan is in place, it is time to begin sourcing the necessary materials.

The most common materials used to construct a catamaran boat are wood, fiberglass, and epoxy.

When choosing wood, it is best to select a species of timber that is strong and durable, such as mahogany, teak, or cedar.

Additionally, the wood should be clear and free of knots, splits, and other defects.

Fiberglass is a lightweight fabric that is resistant to water and provides additional strength to the boats hull.

Epoxy is a waterproof adhesive that is used to seal the boat and ensure that it is watertight.

It is important to ensure that the materials are of high quality, as this will help to ensure the boats longevity.

Additionally, it is important to purchase the necessary materials in the correct amount and size.

Too little or too much of a material can be a costly and time-consuming mistake.

Finally, it is important to keep any leftover materials for future repairs or modifications.

With the right materials gathered, the next step is to cut the wood and begin the assembly process.

Cutting & Assembly

Cutting and assembly are the most important steps when it comes to building a catamaran boat from scratch.

The first step is to decide the design and size of the boat.

This will determine the type of materials you need to gather and the amount of effort that needs to be put into the project.

After deciding on the design and size, you will need to cut the wood to fit the design.

This includes cutting the wood to the desired size, as well as cutting any additional pieces that may be needed to complete the design.

It is important to ensure that all the pieces fit together correctly and securely, as any mistakes could lead to a weak boat.

Once the wood has been cut, it is time to assemble the pieces together.

This involves attaching the pieces together with glue, screws, and nails, and ensuring that the pieces fit together securely.

It is important to be careful and patient when assembling the pieces, as any mistakes could result in a weak and unstable boat.

Once the frame is ready, it is time to lay the fiberglass, and apply the epoxy to seal the boat.

This is an important step, as it will make sure that the boat is waterproof and durable.

Finally, you can add the finishing touches, such as the hardware, paint, and rigging.

With the right amount of patience and attention to detail, you can have your own custom catamaran boat in no time.

Laying Fiberglass & Applying Epoxy

When laying the fiberglass and applying epoxy, it is important to take your time and be precise.

Fiberglass and epoxy are key components of a catamaran boat, as they provide the strength and waterproofing necessary to keep the boat afloat.

Start by laying the fiberglass over the frame of the boat.

Make sure to cut the fiberglass to size and overlap the edges for a strong seal.

Once the fiberglass is in place, mix the epoxy and begin to apply it.

It is important to apply the epoxy in a thin, even layer to ensure a proper seal.

Make sure to move the epoxy around to get it into all the nooks and crannies of the boat.

Allow the epoxy to cure and then you can begin to add the finishing touches.

Finishing Touches

Once the frame of the catamaran boat is built, it is time to add the finishing touches.

This includes adding the necessary hardware, painting, and rigging the boat.

Hardware: Before adding the hardware, it is important to ensure that the frame is stable and secure.

Add the appropriate hinges, screws, and nails to the frame.

Make sure that the screws and nails are the correct size and do not exceed the recommended load capacity of the frame.

Painting: Once the hardware is added, it is time to paint the boat.

Choose a paint that is suitable for the materials used in the construction.

Make sure that the paint is applied evenly and that the frame is completely dry before applying the next coat.

Rigging: The last step is to rig the boat.

This involves attaching the sails, running rigging, and standing rigging to the masts and booms.

Make sure that the rigging is properly tensioned and secured.

Once all of these steps are complete, your catamaran boat is ready to sail.

Hardware & Paint

The last step in building a catamaran boat is to add the hardware and paint.

This step is often the most rewarding, as it is the finishing touch.

Depending on the design of your boat, there are various types of hardware you may need.

Some of the most common items are cleats, winches, fasteners, and decking.

After selecting the required hardware, you will need to install them on the boat.

It is important to use the correct type of screws and bolts, and to secure them tightly.

Once the hardware is installed, it is time to apply the paint.

The type of paint and color you choose will depend on the design of your boat.

It is important to use a high-quality marine grade paint that is designed to handle the extreme environment of the ocean.

If you are up to the challenge, you can add some custom artwork or detail to your catamaran boat.

Adding the hardware and paint is the final step in building a catamaran boat.

With patience and attention to detail, you can create a beautiful and unique boat that will last for many years.

Be sure to take your time and enjoy the process of constructing your own boat.

Once you have finished the frame, fiberglass, and epoxy of your catamaran boat, you will need to move onto the rigging.

This is a crucial step in the construction process, as it will keep your boat safe and secure on the water.

When rigging a catamaran, there are a few key components that must be taken into account.

First, you will need to determine the type of rigging you will be using.

Typically, catamarans use a combination of standing and running rigging.

Standing rigging consists of cables and lines that stay in a fixed position to provide stability and strength to the boat, while running rigging consists of lines that are used to adjust the sail and mainsheet.

Additionally, you will need to choose the right type of rope and hardware for your rigging setup.

The rope should be strong and durable, and the hardware should be made of stainless steel and be corrosion-resistant.

Once you have chosen the type of rigging and hardware, you can start assembling the rigging lines.

This process involves carefully measuring and cutting the lines to the proper lengths, and then attaching them to the mast and boom.

Depending on the type of rigging setup, you may also need to attach the lines to the hulls and deck.

It is important to inspect the rigging lines and hardware regularly to ensure that everything is secure and in proper working order.

Rigging a catamaran boat can seem like a daunting task, but it is essential for the safety and comfort of your vessel.

With the right tools, materials, and attention to detail, you can successfully and safely rig your catamaran boat.

Final Thoughts

Building a catamaran boat is a rewarding experience that requires patience and attention to detail.

With the right plan, materials, and steps, you can build your own boat in no time.

Now that you know the basics of how to build a catamaran boat, why not grab your tools and get started on your very own project? With the right motivation and dedication, you can make your dream of owning a catamaran boat a reality.

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

Does Your Boat License Expire? Here's What You Need to Know

Are you a boat owner looking to stay up-to-date on your license requirements? If so, youve come to the right place! In this article, well cover everything you need to know about boat license...

How to Put Skins on Your Boat in Sea of Thieves? (Complete Guide)

There is a unique sense of pride and accomplishment when you show off a boat you customized to your exact specifications. With Sea of Thieves, you can customize your boat to make it look like your...

Login to Sailing Tellus

Signup to sailing tellus.

By registering an account on Sailing Tellus allows you to import your YouTube channel videos.

If you do not have a Youtube account you can still create an account to enjoy other features.

You have successfully signup on Sailing Tellus.

We have sent you an email with instructions on how to verify your email address.

The email should arrive in a couple of minutes.

If you don't see an email in the Inbox, please check the Spam folder, too.

Forgot password

We have sent you an email with instructions on how to reset your account password.

What is it Going to COST to BUILD a Kit CATAMARAN? - A Comprehensive Guide (MJ Sailing)

The big question on everyone's mind is ... what is it going to COST us to build this new catamaran? Matt has spent the past few weeks talking to the designers at Schionning and Oram, as well as professional and ameture builders to gather as much information as possible on the costs that go into building a kit catamaran. Things can obviously vary from builder to builder, but taking a simple and basic approach, we've narrowed down the numbers on what we estimate it will cost to build an Oram 45R. To take a look at the full design specs, take a look here: https://www.boboramdesign.com/45r For a quick look at the numbers, check our website: http://www.mjsailing.com/cos/oram-45r-estimated-build-cost/ For a download of the spreadsheet, click here: http://www.mjsailing.com/wp-content/uploads/2020/04/oram-45r-cost-1.ods After discussing previous builds with the many others who've come before us, we found out there is one small thing that can skyrocket a budget - and that is making customizations after you've started the build. But, if you start with good plans and commit yourself to them, it is very feesable to stick to your original budget. Sending the above spreadsheet to both designers and builders, and asking if they were realistic figures, they all came back stating that we've covered all aspects and should be able to complete the project within the budget we have listed. And that, is music to our ears!! Since this is a very long video because we have tried to keep it as detailed as possible, here is an outline of subjects covered if you'd like to bounce through to the areas that interest you: 0:00:00 - Intro by Jessica 0:03:50 - Intro by Matt 0:15:32 - Intro To Budget 0:16:30 - Costs relating to Kit 0:21:45 - Total cost of Kit shipped to the US 0:24:23 - Costs relating to Building Supplies 0:32:10 - Total costs of Building Supplies 0:32:53 - Total cost of First Year of Build (getting to paint stage) 0:35:41 - Costs relating to Paint 0:39:05 - Costs relating to Sailing (rig, sails and deck hardware) 0:45:17 - Total costs of Sailing 45:38 - Costs relating to Engines 0:50:42 - Costs relating to Steering 0:52:32 - Costs relating to Electrical System 1:00:50 - Total costs of Electrical System 1:01:07 - Costs relating to Achor (anchor, chain/rope, windlass, docking gear) 1:04:05 - Costs relating to Lights 1:07:17 - Costs relating to Galley 1:12:07 - Costs relating to Exterior 1:16:53 - Costs relating to Interior 1:17:45 - Costs relating to Heads 1:19:12 - Costs relating to Electronics 1:22:20 - TOTAL COST OF BUILD 1:26:40 - Closing by Jessica Enjoy! Much love from England! Jessica, Matt & Georgie Thumbnail photo credit: Christian Loehr Thank you SO MUCH to our Patrons. These amazing supporters help keep us on the boat, our camera equipment up to date, and the videos coming. Without our patrons, these videos would not be possible. To join the Patreon ranks, please visit http://www.patreon.com/mjsailing or Buy us a beer through PayPal! https://www.paypal.me/MJSailing or Help us get items for the boat off our Amazon wish list! https://www.amazon.co.uk/hz/wishlist/ls/2GACKY1NTGG8G?ref_=wl_share Thank you!, Matt & Jessica -- Our Online shop: https://mj-sailing.myshopify.com/ Videos made by Jessica, featuring Matt and Georgie. Camera equipment used: - Panasonic Lumix G85 - http://amzn.to/2iv2g4G - Shure VP83F shotgun microphone - https://amzn.to/2rsIHLL Our boat: 1983 Trisalu 37 (custom aluminum, built in Quebec) Where we've been: 2.5 year refit in Indiantown, Florida; Abacos, Bahamas; St. Barth's; St. Maarten; Antigua; Saba; Azores; Ireland; Scotland; Norway; England Our Previous Boat: 1989 Sabre 34 Targa (Serendipity) Where We Sailed Her: U.S. - Bahamas - Jamaica - Cuba - Cayman Islands - Honduras - Guatemala - Belize - Mexico - Bermuda - Azores - Madeira - Canary Islands - Sint Maarten - BVI's - USVI's Editing software: Adobe Premier Pro Website: http://www.mjsailing.com Facebook: http://www.facebook.com/mattandjessicasailing Instagram: https://www.instagram.com/mattandjessicasailing & https://www.instagram.com/mj_wayfaring/

More articles from MJ Sailing

You might also like

- Tokyo Express

- Small Boats

- Geelong Model 850

- Plans (all)

- Noosa Plans

- Tewantin Plans

- Geelong Plans

- Daggerboard Plans

- Daggerboards

- Consulting / Drafting

- Terms & Conditions

- Privacy Policy

Select Page

- How much does it cost to build a boat – a 40ft Catamaran?

Posted by Tim Weston | Sep 19, 2017 | Building | 6 |

How much does it cost to build a boat?

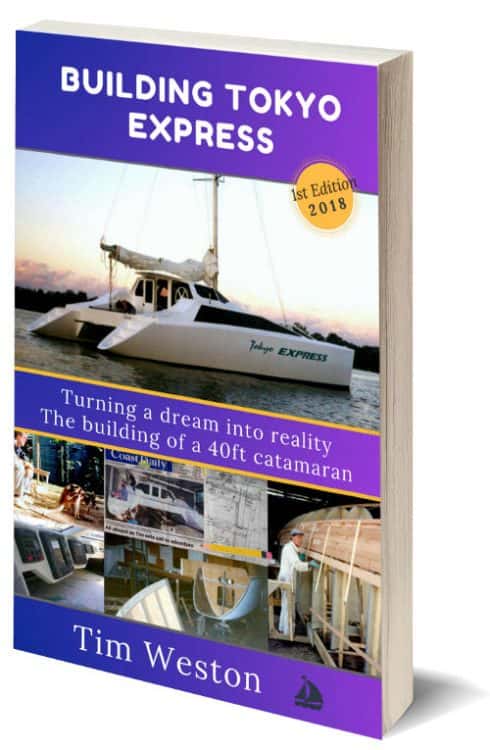

A question I often get asked is; what is the cost to build a boat like Tokyo Express?

What are the costs to build a boat of this size? It’s a good question and a topic I spent a lot of time trying to work out myself before I began.

Second-hand boats are cheap these days, although cats still hold their price better than keel yachts. With the interior fit-out work included, I put in close to 8,000 hours of work, creating my boat. But that also included building a shed, designing a lot of my own things – everything.

It can be done quicker than I did, but there is still a lot of work involved. Putting an hourly rate on your time spent building a boat, and adding that to the cost of materials, may make it appear an expensive exercise.

Some people suggested I was wasting my time putting in so many hours when 2nd hand boats are cheap. Just go out and buy one! If you are well paid, and the only reason for making a boat is saving money, then maybe it is better working longer in your day job and buying a boat.

Comparing apples to oranges

But my reasons to build were not just about saving money .

Building my boat was one of the most rewarding things I’ve ever done, it falls more into the category of a hobby. I lose track of time whenever I’m in my shed creating, even on small projects.

Making a craft you can live on, and sail across an ocean with, takes it to another level. The joy and satisfaction I felt, launching a boat I’d spent the last three years building, are not something money can buy.

You will never feel the same about a boat you buy as the one you have built. Creating your own craft also gives you the chance to make it how you want, and build it to meet your standards. Even if you are building from plans, you can still make plenty of changes and tailor the boat to fit you.

So calculating the cost of the hours I worked and adding that to the material costs, and comparing that to buying a boat, for me, doesn’t tell the whole story. It is like counting the hours you spend playing tennis, or whatever your hobby or sport is, then working out how much money it costs you in lost work hours. Maybe it’s not quite the same, perhaps it’s somewhere in between.

I built because I loved doing it, and saving money was a nice side effect of doing the job myself. When I added up the material costs without counting hours, it was a lot cheaper than buying a boat. Also, it was built to my standards and the way I wanted it. And it was a new boat. You might find a second-hand boat cheaper, but it is just that, second-hand. That’s comparing apples to oranges, it’s not the same thing.

Now, to answer the question.

The cost of raw materials and equipment to build TE, added up to around $75,000 (AUD), in 1995. Things have gone up since, but something’s not so much. In fact, some items are cheaper these days. To put things more into perspective.

- Epoxy cost me $13/litre back then – buying 200 litres bulk at a time. (The price in Oz for buying 20 litres in 2016 was $24/litre).

- Paint I think, is cheaper these days.

- Wood hasn’t increased too much.

- Electronics are less expensive (and better).

- Solar panels now cost less than 1/10th of what I paid.

- Tools are considerably cheaper today.

I sold the boat for about 3 times more than the material costs, after living 5 years on board, which is in line with the rule of thumb I’d heard many times, that the material costs are half to one-third the value of a boat.

I think it’s rare to get the same sense of satisfaction working in a job for someone else, compared to being your own boss, managing your own project. So while my “hourly rate” was not that high, if you want to look at it that way, I did earn money when I finally sold the boat, and they were the most enjoyable 3 years work I’ve ever done.

In my book “ Building Tokyo Express “, I talk more about the cost of building and describe how I built my boat. I had more time than money and made a lot of the systems and major components, that you would usually buy or have made, myself. It saved me a considerable amount of money. You can weigh up for yourself if it is worth it or not.

If you have more money than time, you can get some or all of that work done for you and finish the boat quicker. The timeline in the back of the book, details how long it took me to complete each part of the boat along with many ideas and things I learned during this time. It can be done a lot more economically than you may first think.

You might also be interested in the following post, which compares the advantages and disadvantages of catamarans vs monohulls . There is a big difference!

I hope this gives you a little more insight into the costs of building your own boat.

Share this:

- Click to share on Facebook (Opens in new window)

- Click to share on Reddit (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

- Click to share on Pinterest (Opens in new window)

Related Posts

Skills required – building a boat.

November 22, 2016

- Keeping safe – while building your boat

March 25, 2018

Boat building with a CNC router

June 30, 2017

Boat building – first Tewantin taking shape

August 29, 2017

thanks ,,, great information and great professional designs . I know ,because I was born in Alameda california

Tim, I’m reading your book and checking out your website. I have built a nine meter Jarcat in my backyard in Adelaide and launched her in 2002 after five years of building. I have modified the plans with the designers consent (twice) and I now live on Lake Macquarie with ‘Cobwebs a drive to the ramp, put the dinghy in the water and get onboard all within ten minutes. ‘Cobs isn’t an ocean crosser but she is a very nice coastal cruiser. She cost me around $70k but I made a few expensive mistakes, like buying and fitting a diesel motor only to change it over for an 18hp four stroke outboard. I also had a stainless canopy, liferails, pushpit and pullpit made which was about 10 percent of the total costing. Like you I’m a fitter and turner l and have designed and built a number of fittings in stainless and aluminium. I built the steering wheel for less than $30, the new ones being over $400 at the time. I am enjoying your body of work and can relate to a great deal of it, I find we have the same philosophy towards things boatie, best regards Ross C.

Hello, Ross. Thanks for your comment. Yes, we have similar philosophies and fitter backgrounds. A good trade to come from;) It’s a good feeling to be able to make things, that are just as good or better than something they try and sell us at 10x the price. Your boat sounds great, and you are still enjoying her. I need to get back on the water too. Take care. Tim

Hi Tim, I watched all your videos and left a comment, to which you kindly responded. I am really thinking seriously about this now and although I have no way of building it myself because I am fully engaged in my business, it happens that my business is a factory and I have workers or can hire a few more to help me with this. I was just looking at the Arrow 1500 and I think I can build that much cheaper than they suggest, which is A$290-350k for materials, assuming you buy their kit I presume. I won’t be buying that. Their full plans, manual and support cost A$19,500 which, for a professional design with support, is probably reasonable I think. I do not want their onboard motors or big fuel tanks. Your idea for the Tokyo Express was brilliant I think. I would look at building a compartment to take a couple of outboards and put them on vertical slide rails with an electric actuator to drop them down vertically into the water through a sliding trapdoor. I think this would save a heap of space, be far cheaper than diesels and be a lot easier to maintain.

They estimate that this would take 7000 hours to build. http://www.schionningdesigns.com.au/arrow-1500 For me the cost of 7000 hours is less than US$30k, not counting any time from me. I will source most of the materials locally and use our own wood for the hull and fitout. I don’t want to use their sandwich panels, I will do it the way that you did back in 1995.

If I can afford to do this, the plan would be to sail down the Yangtze and head over to Japan. After a few short runs based out of Mizushima, I will sail back to Perth to retire on the coast. Ideally a place with a berth for the boat. This one looks good! https://www.domain.com.au/33-2-the-palladio-mandurah-wa-6210-2016381113 The flat is a bit small, but the boat would be great guest accommodation. Maybe with A/C plugged into the mains!

I will download your manual and get your book sent to me. I can’t buy it online from here. I will let you know how I go. Send me an email and I will keep in touch. If you get to Perth in about 4 or 5 years time (after I retire) you will have a place to stay. Regards Terry

Hi, Terry. That sounds like a great plan you have. You have the most important thing already, a place to build. I wouldn’t build from a kit either, that is why they costs you quote are so high. Strip plank is a great way to go. All the with your planning, Terry. My email is [email protected] . 👍

Hi Tim, really like your videos and webpage, I’m going to buy your book, I was thinking to build a catamaran, but I question myself if it is not better to build a bigger trimaran, assuming that is much less material comparing the same lenght. So instead a 40 foot cat I could build an 60 foot tri, what do you think? have you thought to build a tri?

What do you think? Leave your comment.. Cancel reply

Search site, new book – just released.

Watch the Video Series – (1 hour & 45 mins)

Recent Posts

- Catamaran vs Monohull

- Going fast – in small boats – hull speed.

- Catamaran size – how big a boat do you need – ocean sailing

Get the Guide – Free

Privacy Overview

[email protected]

Category: Our Catamaran Build Kits

Recommended equipment.

Quality suppliers & manufacturers

The schionning team have a lot of contact with equipment suppliers and manufacturers, and hear feedback on certain brands or systems from our many customers. there are many schionnings cruising the world and testing products longevity and the customer service offered by the manufacturer., on this page we will list products and companies that we know to provide above average quality and service. it is always growing, and if your company provides equipment used on our designs and you would like to be included - please contact us., engines & drive systems.

Visit: https://oceanvolt.com

Batteries, Power Management

LITHIUM POWER (VIC)

Back in 2013 I knew that my boat batteries were reaching the end of their lives, I had been researching LiFePO4 cells for a few years and decided that I should install them. Unfortunatly I was unable to find a local supplier. So Lithium Power was established.

Technical Information

The technical information page is a collection of documents (mostly in pdf format) on the materials and systems used in schionning catamarans. including data sheets, engineering information, strength comparisons of each core material and informative articles from jeff outling the design of certain system such as engine choices and main sheet systems., detailed engineering data for your research, we understand that getting your head around the process of building your own boat, or having one built, can take a little while. to gain a greater understanding of the materials used in our designs, the below data sheets have been supplied by atl composites, and contain all of the technical data you could need regarding the composites we use. in addition are articles or documents written by jeff about certain systems used on our designs and why., all technical information and data sheets on west system/duflex/durakore provided courtesy of atl composites. for more information please see the atl composites website here., documents library.

Information Sheet – CE CERTIFICATION PROCESS

- Mainsheet Systems for Catamarans

- Motor Choices for Schionning Designs

- Weight and Weight Distribution Schionning Designs

- Schionning Designs Sailing Performance and Tips

- Hull Shapes and Performance – Power Designs

- Outboard Engines VS Diesels – Written by Ross McCombe

- An Outboard Installation That Works – Ross McCombe Follow up

- Data Sheet – DUFLEX BALSA for Catamaran Kit Builds

- Data Sheet – DUFLEX FOAM

- Data Sheet – FEATHERLIGHT Paper Honeycomb

- Data Sheet – WEST SYSTEM R105

- Data Sheet – PUMP SYSTEMS

- Data Sheet – MICROFIBRE BLEND 403

- Data Sheet – MICROLIGHT 410

- Data Sheet – MICROSPHERES 411

- Information Sheet – USING FILLERS

- Data Sheet – KINETIX RESIN Thixotropic

- Information Sheet – DURAKORE PLANKS 413

- Data Sheet – DURAKORE PLANKING 414

Kit Materials Contents

Kit materials' contents, so if you order a schionning kit, what exactly is going to arrive see an overview of the materials you will receive, and what each is used for during the build process. fibreglass cloth or tapes microspheres, microballoons or microfibers take a closer look and you can answer these questions., our schionning kits are a no nonsense, common-sense approach to building a boat. we offer great service, fast delivery and access to anything you could need for your boat straight from the supplier to your door. our construction plans and kits are sold with 100% professional boatbuilder support via phone and email, any time you're unsure or just need a second opinion, we're here..

Our kits contain all of your basic materials to build your boat to a faired shell stage, ready for painting and fit-out. We have sail-away costing estimates available for all of our standard designs, and this will give you an accurate idea of the overall cost of your project. This costing varies depending on your level of finish, as you can imagine different options vary greatly in price.

Below is a quick glance at what your Schionning Kit will include and what each item is primarily used for, we hope this is helpful and if you should require more detailed information please don’t hesitate to contact our office.

What do I actually receive?

DUFLEX PRE-LAMINATED PANELS

DuFlex pre-laminated panels are the main and most important material used in our kits, predominantly in the flat panel designs, however they are used in Strip-planked designs also, though to a lesser extent. These panels are 2400mm x 1200mm and are CNC routed to speed up build time on our Wildernes X Series, as well as some of our power designs. For internal furniture, a paper honeycomb core is used instead of the end-grain balsa wood core that is used for main structural areas. The use of this is purely to save weight in the shell and therefore produce a faster, more responsive catamaran.

KINETIX LAMINATING RESIN & HARDENER

WEST SYSTEM EPOXY RESINS

FIBREGLASS TAPES (DOUBLE BIAS)

CARBON FIBRE CLOTH

FIBREGLASS CLOTH

The kit process, building your own boat can be a daunting prospect, however to demonstrate each step in the kit assembly process, we've created this guide for you to study. as you can see our kits are the ultimate in building efficiency and have been streamlined over 30+ years to ensure that you're on the water faster and with less effort., how does it all go together.

The first step to building your dream catamaran begins with a strongback – this is a square frame used to position the temporary frames that will be used to form the hull shape. This frame will be set up and must be square and accurate, a string or laser level can be used to achieve this.

The forebeam is now installed along with the striker attachment fitting, as shown above. The bridgedeck is installed shortly after and taped onto the bulkheads with webs installed, this now completes what is a quite stiff and strong platform to work on.

Now that the bridgedeck is in place, the forward webs and dash will be fitted. At this stage, all furniture and internal work begins, with the main panels left off for ease of access when working.

Material Choices

Schionning material choices, solutions that work best for catamarans & why, our designs are based on cored composite construction techniques using west system epoxy resin and knitted fabrics. but given the range of today's composite technologies, which solution works best for catamarans and why written by jeff schionning, selecting the correct materials, resin choices.

It also fully protects the boat against water absorption and it can not develop the dreaded Osmosis.

We choose ATL Composite’s resin systems for their superior quality, reliability and value for money.

Having worked closely with the ATL Composites team and their products for many years, we know we can stand by their material solutions, and rely on great service should something unexpected happen.

This may not seem important but when working with a material for an extended period of time, the small things make all the difference.

CORES Which One to Use?

- End-Grain Balsa – 150kg per cubic metre

- Superlight Balsa – 94kg per cubic metre

- Western Red Cedar – 360-380kg per cubic metre

- Foam – 80kg per cubic metre

BALSA END GRAIN (150 kg/cubic metre)

Balsa has very good values and we can produce a shell using a very light laminate. It will be very stiff and very resilient to fatigue.

It has exceptional qualities including very high compression strength, extremely good sheer capabilities and fantastic sheer stiffness.

Compressive strength is the resistance to collapsing when pressure is applied perpendicular to the surface as when pushing directly onto the material with the point of your finger. Balsa is far stronger than Foam (80kg/cubic metre) in compression.

Balsa is also very strong in shear. This is when the core sample is held flat between your hands, one hand slid one way and the other slid the opposite way, when the core tears through the middle the core has failed in sheer. The amount of stretch you feel before the core shears is shear stiffness. To compensate for sheer weakness the core is made thicker. So 13mm Balsa may be equal in sheer to 19mm Foam.

(80 to 200 kg/m³)

There are many boats sailing that are built from foam as it’s mechanical properties are good for boat building.

- Initially one would expect this cat shell to be lighter as it is ½ the weight of Balsa. We do have to compensate for its weaknesses and will then add to the reinforcement the reinforcement on the outside to spread that compression load over more core and need a triaxial type weave to compensate for the veneer content that runs fore and aft on the Durakore.

- Secondly, we need to increase the Core thickness to compensate for the shear value, usually neutralizing the weight advantage.

- We only use structural foam core that is closed-cell and cross-linked.

The end result using foam core amounts to a very similar total boat weight. Professional builders can achieve a good result but usually use vacuum bagging and very good molds to achieve this.

Secondary Issues

Balsa can absorb water. It needs extreme neglect to rot (very unusual). Water soaks along the end grain quickly. It travels very slowly across the grain. We use balsa under the waterline especially because of it’s high compression strength for beaching etc. any core type must be sealed. Damage to all cores results in the same sort of repair. Notice a damp spot remaining when drying out to anti-foul… simply grind back the surface glass exposing the core, dry it out and re-glass – it’s that easy.

Timber cores are cheaper than Foam in most cases.

A light, high tech cat returns a far better (often 2 – 3 times) re-sale than lower tech materials. Often saving $10,000 on materials initially, loses $200,000 on re-sale – a serious reality.

Our boats can be built using Balsa, Foam or Western Red Cedar. Combine strength, stiffness, lightness and cost, with ease of use – it just makes good sense!

Time For a Catamaran Adventure

Isn't Time For Yours?

Construction Costs

What are the construction costs for a catamaran.

The total construction cost in 1999 to build our 28 foot Woods Gypsy catamaran was $60,000 USD for a 4,000 pound boat. This works out to $15 per pound.. This was for a basic equipped boat that we sailed in for a couple of years. We have added a further $20,000 over the last 7 years to get it offshore ready.

Our boat is valued at $120,000 USD so for our 3,500 hours of work we made abut $11 per hour (after tax value).

My rule of thumb is that is for a basic catamaran that you can take out cruising, you will spend $15 per pound. If you want to have it equipped for offshore trips and long term cruising you are at $20 per pound. If the boat you are comtemplating building has an empty weight of 8,000 pounds you wil spend between $120,000 and $160,000. With the 7,000 hours you would put into it, it would be worth around $250,000 USD.

- FUSION THE SMART CHOICE

- BUILDING YOUR DREAM

- FUSION THE BOAT

- TESTIMONIALS

Construction Flexibilty:

By producing this modern catamaran in modules, which in turn fit in containers, it has meant delivery is simple and it has opened the doors to worldwide marketing of the Fusion 40. The cost savings on overseas shipping as deck cargo, is in excess of $40,000.00. Private contractors are available to assist with assemblies to any stage if you desire.

For more information on this fabulous product, or even where the closest one to you is, please click here to contact us .

Average Cost of Buying & Owning a Catamaran (With 4 Examples)

Turns out that owning a catamaran is pretty affordable. Not cheap, but it can absolutely be done on a budget. In this article, I'll show you what to expect.

Sure, there are plenty of unimaginably expensive catamarans available, but a modest, used open catamaran can be as cheap as $6,000 and an additional $1,000 per year.

A new catamaran costs $144,000 on average at 30 foot, while a used one will cost between $29,000-$134,000 on average. New catamarans cost $751,000 at 50 foot, while a used one ranges from $203,000-$690,000. The average annual cost ranges from $2,805-$10,950.

Of course the price of a catamarans depends on many factors, like the size for example, and your choices determine whether owning one is a rich man's game, or actually a very good holiday investment.

It may come as a surprise that you can get a decent 34-foot catamaran for as little as $25,500 on Craigslist.

This will be a long article because there are so any aspects to cover. I'd like to spend some time exploring the costs of actually buying the boat . Then I want to go into recurring costs , like mooring, maintenance, and insurance.

Cost of buying a sailboat

If you're also eager to find out what regular sailboats cost on average, I have published a very similar article on that topic. Sailboats are a lot more affordable than catamarans, so if these numbers startle you, you could check out the cost of regular monohulls .

But first, to get a good sense of the ballpark amounts, I'll give some real-life price examples, like:

- what does it cost if you want to keep your cat in good shape and have a good sailing experience? - aka: most people

- what does it cost if you ONLY spend the absolute minimum amount to keep her floating?

- if I want to sail the world on a budget, what's the absolute minimum?

- if sailing is more of a status thing to you, how much money COULD you spend?

On this page:

Examples of popular catamarans and how much they cost, what does it cost to buy a catamaran, what does it cost to own a catamaran, catamarans are 60% more expensive than monohulls.

There are a lot of great boats out there for a good price and there are also some boats that are so expensive (or so cheap), it's not even fun to look at them.

But one thing's for sure: there are plenty of boats available, and even if you're on a very tight budget, you could absolutely still make it work. Sailing is in and of itself actually not that expensive: wind is free, water is free, boats can be cheap - if you're willing to look around a bit. It's all the little extras that add up quickly.

Listed below are four boats that make great beginner boats. Since more than 80% of all boats that are bought are second-hand, I'll use the prices of used boats I found on Craigslist and Yachtworld.

If you want to know exactly where the numbers come from, don't worry, I'll explain them after the four examples.

1. Sea Cat 226DC 22' for stressless weekends on the lake

Boat: Sea Cat 226DC 2007 22 foot The one-time costs are $53,615 Your total recurring costs are $9,510 per year, or $793 per month

Let's say you're like me and most other people and just want a nice cat without too much hassle. So you pay people for any important maintenance that's not easy to do yourself. You do the required maintenance and save up for future repairs. You do a little yourself, which saves you a couple of hundred of bucks a year. You also join a (cheap) sailing club to learn how to not trash the boat.You don't want to buy a bad boat, so you pay a fair purchase price.

One-Time Costs

Recurring costs.

2. Extreme Low Budget Kantola Mach II 35'

Boat: Kantola Mach II 1968 35 foot The one-time costs are $26,440 Your total recurring costs are $2,805 per year, or $234 per month

Let's say, for argument's sake, you want to buy the cheapest cat you can, saving as much money as possible on repairs and annual costs. How cheap could you theoretically go without ending up with a trasher?

I think something like this old but sturdy Kantola Mach II will be right for you. It will save you massively on the purchase price. However, beware, you'll have to antifoul the boat next fall, which will cost you (roughly $2,000). It's common with very cheap boats: upcoming maintenance. But if the current owner is fair and discloses it, you may get a good deal.

In this case, you won't join any clubs. You'll simply do the most important maintenance to keep the boat from falling apart, find a nice mooring place in a far-away (cheap) location, and sail along quietly and affordably.

3. Low Budget 35' Cruising Catamaran for traveling the world

Boat: Gemini 105 1996 Cruising Catamaran 35 foot The one-time costs are $85,850 Your total recurring costs are $10,950 per year, or $913 per month

Let's see what it would take to get a good bluewater cat with all the features you'll need to sail across the world on a budget. In this scenario, you buy a fairly priced, not too old cat that is ready to cruise. Something like this Gemini 105 1996 will do.

Not too long, but comfortable enough for extended onboard time, reducing length will greatly reduce cost as well. With boats, you pay per foot, both in maintenance, fuel, and docking costs.

You don't join a sailing club, reserve quite a bit of change for your maintenance fund (since you'll be bluewater sailing), but you don't need to winterize the boat, as you'll simply sail to the Bahamas and stay in the warm waters there. Or at least, that's what I'd do.

Your mooring costs will be somewhat higher, sailing to and from more popular destination, but your overall monthly cost won't exceed your monthly mortgage or rent payments, and you could permanently live onboard without problems.

You'd need an ICC (International Certificate of Competence) to be able to cross all international waters. You can learn how to get your certificate here .

4. Luxury 52' Cruising Catamaran

Boat: Shuttleworth AeroRig 2022 52 foot The one-time costs are $2,326,020 Your total recurring costs are $53,400 per year, or $4,450 per month

So what if you're in it for the fame? Well, don't worry, there are many status symbols to be had and there is plenty of cash to be burned.

In this case, we buy a new cat of 52 foot, which is not overly decadent, but it's a real piece of gear nonetheless. This Shuttleworth AeroRig comes equipped with all the comfort and luxury you'll need for extended cruising in style.

Of course, you'll pay for joining a decent club, since that's where you can show off your rig. We'll also invest something extra into equipment, regardless of the full electronic rig that comes with the boat.

The annual costs will be high due to mooring fees, the club, and pretty hefty winter storage fees that come with a boat this large.

Unlike monohull sailboats, the price difference between new and second-hand catamarans isn't as great. Regular used sailboats go at a 65-75% discount, while the discount for an average used catamaran is just 10% .

The price difference becomes more noticeable the larger you go, with second-hand catamarans of over 75 foot going at a 35% discount , but that's as high as it gets.

Size and condition affect price the most

There are a couple of important factors that determine how much money you end up spending.

- Size - length determines mooring costs, insurance, amount of paint on your hull: literally everything gets more expensive with every foot of length

- New vs. used - of course, it makes all the difference whether you buy new or used. Typically, the price of a 35-foot used catamaran vs. a comparable new one is 10% lower (ie. $237,714 vs. $261,286).

Price of new catamarans

The price of new catamarans ranges from roughly $1,765 - $54,491 per foot. An average length catamaran costs between $144,000 and $505,000 (30 - 45 foot). Some go for as low as $42,000 to as high as $924,000.

I've looked at the prices of thousands of catamarans (really) on one of the largest yacht marketplaces in the world (- not manually, don't worry: with the help of their search function). This is what I came up with:

Average price new catamaran per foot in USD:

Catamarans get a lot more expensive from 50 foot and up:

- under 30 ft: $2,835 per ft

- 30 - 50 ft: $9,767 per ft

- 50 - 75 ft: $18,055 per ft

- 75 - 120 ft: $41,737 per ft

Purchasing price new catamarans

Source: Yachtworld.com , Q2 2022

Price jumps at these boat lengths

As we can see from the data above, the average price per foot drastically increases for new boats at the following lengths: 25 foot, 35 foot, 40 foot, 60 foot, 75 foot, and 100 foot . Buy just under these lengths to get the most boat for you buck.

Price of used catamarans

The price of second-hand catamarans ranges from roughly $756 - $39,909 per foot. An average length catamaran costs between $134,000 to $467,000 (30-45 foot) on the second-hand market. Some go for as low as $29,000 to as high as $848,000.

We did the same for used catamarans, comparing thousands of listings. Here are the complete data:

Average price used catamaran per foot in USD: