- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

In Search of the Snag-free Clew

What’s Involved in Setting Up a Lithium Battery System?

Reducing Engine Room Noise

Breaking Point: What Can Go Wrong With Your Yanmar?

Mildew-resistant Caulks for Boats

Can We Trust Plastic Boat Parts?

Repairing Molded Plastics

Mailport: Marine plywood, fuel additives, through bolt options, winch handle holders

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Safer Sailing: Add Leg Loops to Your Harness

Resurrecting Slippery Boat Shoes

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

The Ultimate Guide to Caring for Clear Plastic

- Belowdecks & Amenities

Navigator Wood Stoves Provide Classic Heating and Cooking Onboard

Custom-made, cast-iron stoves are functional works of art..

Tucked into a wooded hillside in the San Juan Islands of Washington state, Navigator Stove Works is a young family operation attached to a long history of vintage stoves. Formally of Brooklyn, N.Y., and now based on Orcas Island, Navigator produces three compact wood-burning, cast-iron stove models for use on land and at sea. Originally designed for use aboard boats, the scaled-down stoves are also popular for cabins, RVs, and other small structures on terra firma.

Two of the Navigator stove patterns-the Sardine and the Little Cod-originally were made in the Lunenburg Foundry in Nova Scotia, Canada. The company, founded in 1891, manufactured a wide range of marine equipment for commercial vessels and yachts. Lunenburg ceased producing stoves in the early 1990s with the closure of its iron foundry operations. Navigator produces the Sardine and Little Cod using Lunenburgs foundry patterns.

The third model, the Halibut, is designed by Navigator and is based on old East Coast favorite, the Shipmate No. 212. Navigator also has a fourth stove in the works: a biodiesel prototype, the Herring. The Navigator stoves are custom made by order only, and the company is currently producing about 75 a year.

Safety First

As with any stove or heat source aboard, users must follow manufacturers installation instructions explicitly and heed their warnings to ensure safe operation. Installed in accordance with the manual, all Navigator stoves meet American Boat and Yacht Council liquid and solid fuel boat heating systems standards. These and other applicable U.S. and Canadian fire standards are also outlined in the manual, which all prospective buyers should study closely. For safety reasons, the stoves should not be used on a gasoline-powered boat.

The iron stoves are cast in the northeastern United States and then shipped in sections to Andrew Moore at Navigator Stoves on Orcas Islands. The stoves are sold as plain iron with a traditional stove polish, but a customer can opt to add one of six porcelain enamels -grey, black, mint, deep mariner blue, dark green, or classic barn red.

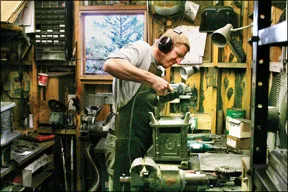

Moore prepares, polishes, and smooths the iron on each stove at his workshop, and then tweaks and assembles those ordered as polished iron. Stoves that are ordered with the porcelain coating are sent to the Midwest for coating, then flat-packed back to Moore for polishing, tweaking, and assembly. Lead times vary from one week to eight weeks, depending on availability.

All three stoves are designed to burn natural wood and charcoal. The two smallest models are best for heating 300 square feet or less. The largest model, the Halibut, is able to burn coal. The stoves are not intended for use with any other fuel sources. For use in warmer months, Navigator has designed alcohol drop-in burners. The drop-in burner literally drops into the stove top and burns denatured alcohol. The burner element is self-pressurizing and is located in the cast-bronze burner housing to minimize fuel spills. One 2-ounce filling will burn for 20 minutes. Running in simmer mode, the burn time is doubled. Tests show it takes 8 minutes to boil a liter of water. The alcohol can be refilled for longer cook times.

Navigator Stoves also sells many of the accessories associated with installing and maintaining a wood burning stove, including stove pipes, deck heads, and heat shielding. Heat shielding can be a critical issue, and Navigator offers custom-made shielding panels made from either 20-gauge stainless steel or 16-ounce copper.

The smallest and most popular model, the Sardine is a mere 12 by 12 by 11 inches, and weighs 35 pounds. The heat output is 7,500 to 18,000 BTUs.

Navigator Stoves suggests using this rule of thumb for determining required BTU: 15 x volume of space to heat = required BTUs. If extreme cold temperatures are expected, one might want to use a factor of 20. This compact Sardine is best suited for small boats or sleeping cabins aboard larger vessels. It is two-thirds the size of the Little Cod and costs $699 for plain iron and $1,199 for the porcelain enamel option.

First produced circa 1917, this solid-fuel stove was initially designed to keep fishermen warm and well fed as they jigged for cod. Simple and reliable, it is economical to run and maintain. It is intended for use in the galley, cabin, or pilothouse, or small spaces on land. By adding one or two of the alcohol drop-ins, it can essentially replace any alcohol stove onboard. The Little Cod measures approximately 13 by 18 by 14 inches and weighs 55 pounds. It produces 10,000 to 28,000 BTUs. It has a stainless-steel sea rail to keep cook pots in place, and has holes in the legs for securing stove to a platform. It is priced at $1,125 for iron and $1,675 with porcelain or $1,875 for red porcelain.

The Halibut has cast-bronze sea rails and corner posts. It has a glass firebox door, stainless-steel ash pan and oven rack, an oven thermometer, and a Halibut relief on the door. The Halibut doesn’t come up to temperatures as fast as the little stoves, but it does offer the oven for onboard cooking of bread, potatoes, and pies. It can also burn coal, whereas the smaller stoves are designed for wood and charcoal only. The platform size for the Halibut is 26 inches wide minimum, and 18 inches deep. The oven is 9 by 9 by 8 inches, and the stove weighs 175 pounds. The approximate heat output is 25,000 to 35,000 BTUs. The stove costs $2,850 with porcelain.

Herring Prototype

Navigator Stoves is also currently working on a diesel/ biodiesel prototype stove. It is intended to be 28 inches tall with a 12-by-12-inch footprint, and weigh 55 pounds. The Herring will have a glass-plate front and a herring relief on the front plate. It is designed with a “blue flame” natural draft burner from Europe and no fan or electricity is required. Tests by Navigator have shown a very clean, steady burn. The expected BTU rating is 16,000. Navigator is also working on a design for a water heating loop.

The Navigator stoves are functional art, a nostalgic throwback to simpler times. If convenience is your top priority, then don’t bother. Like any wood-burning stove, these come with soot, ash, and smoke, all of which can find its way onto the deck and cabintop. The cast iron construction is rugged, but it is also heavier than other heating options. Wood stoves take longer to heat up then a gas oven, and they require supervision and maintenance. But, notes Moore, that is the point, really.

A woodburning stove involves the sort of philosophical shift that a wooden boat requires: Convenience and ease of maintenance are not the aims. If you subscribe to the idea of a lifestyle of the present, in which you tend your fire, not just switch it on, then these well built, finely finished stoves fit the bill.

The stoves can be installed by an experienced and involved do-it-yourselfer in a couple of weekends, with the lions share of the time dedicated to thinking and planning, rather than installing.

- Practical Sailor Value Guide: Woodburning Stoves

- Download PDF Format

RELATED ARTICLES MORE FROM AUTHOR

Have a Tiny-Tot wood and coal burner on my Mason. Custom tools for tending. Makes it easy to keep clean. Fire it up early. Easier to maintain the daytime heat than to start from scratch. Reload later in the eve, good all night. Wake up to a warm boat.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Island Packet 370: What You Should Know | Boat Review

How To Make Starlink Better On Your Boat | Interview

Catalina 380: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Once the overall scheme was signed off by all, it was time to start with the surgery. Any sailor knows the trauma of adding a new hole to the boat, even above waterline… and this one was a doozy: a very large opening in .2″ steel topped with Treadmaster, backed with a very dense .75″ marine ply, and blocked for the extricated pole amidst an expanse of foam insulation filling a grid of steel ribs. After much head-scratching and calling out reference marks ‘twixt deck and pilothouse, we punched a pilot hole, then broke out the jigsaw. Here, Andrew’s assistant Jeff from Indian Summer II is carefully slurping up any remaining steel bits to prevent future rust spots…

The guys headed back to the shop to conjure a few parts, including a trim ring that compensates for the 5° camber of the deck and supports the beautiful cast bronze deck iron . This was all bedded in place using screws for clamping pressure, prompting the first of many comments that it looks like it was meant to be that way. (2012 update: I later had serious leak problems because the Treadmaster was not cut back far enough to allow a fillet of sealant… and various sealing problems developed including failure of the primer-Dolphinite interface and a crack in the trim ring from too much screw tension on the curved deck surface. I finally pulled the ring, which popped off with no effort, gave it a proper coat of wood sealer followed by Brightside polyurethane, then bedded it with 4200 after cleaning the old residue) :

This made for a nicely finished exterior appearance, but from below we could still see the wood “underlayment” – meaning that it would be exposed to radiant heat as well. The hole had been lined with copper sheeting as a first step:

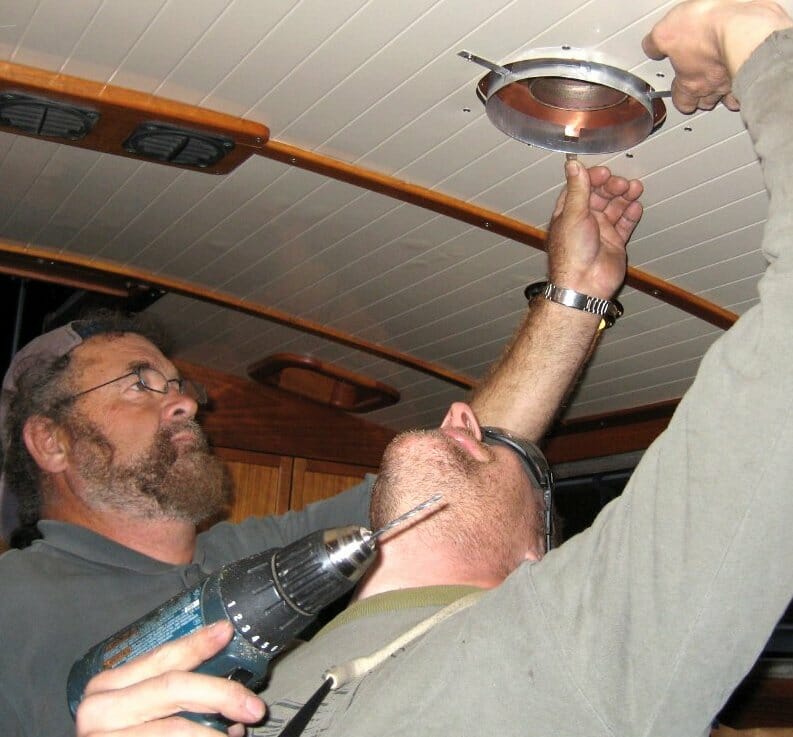

In a flash of inspiration, Andrew conjured a pair of aluminum components that would further reflect heat while allowing cooling airflow. It also prompted one of many amusing photographic moments, given all the awkward angles necessary when working on a boat…

With the hole prepped, it was time to get the stove mounted. They used the cannibalized wood from the original pole to frame out the plywood wall at the end of the galley counter, allowing a clever hack in which a routed channel created clearance for a row of 1/4-20 T-nuts. The whole assembly is thus removable without dragging out the refrigerator that’s on the other side of that wall… a process that is complicated further by having to remove the foot pumps under the galley sink to provide enough fridge-movement clearance to get an arm into the cavity. Boats are for contortionists, something I am most emphatically not .

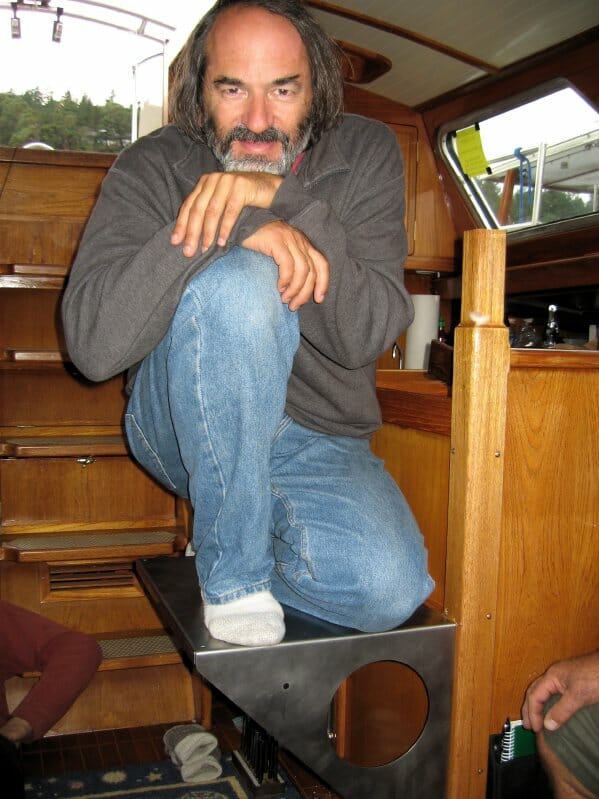

When the shelf was installed, Andrew immediately insisted that I park on it to convince myself that it is sufficiently robust…

With that test passed, he added a stainless heatshield to protect the wood… and then the stove was centered and bolted to the shelf, its tripod legs insuring that no amount of heat-induced casting warpage would cause rocking. A few leveling washers induced general positioning consensus, then it was down to the final steps.

Pipefitting is something of an art, it turns out, and I was surprised at how fiddly this part was… but patience and collective insistence on perfection eventually yielded a smooth and well-considered run. Here we are eyeballin’ and tweakin’…

Now you can see the final configuration of the deck-iron interface, with the heat shield spaced away from the headliner giving a strong sense of the etymology of stove-pipe hat :

Topside, we have a couple of operational choices. The smoke head can be plugged directly into the deck iron for a low-profile look like this:

Or, as is the case at the moment in the oppressive wind and rain of an incoming cold front, we can insert a 2-foot pipe section to improve draft and disperse the startup smoke above the level of the dodger:

And it’s done! With the pipe all fitted and already showing a patina from the test-firing, here are three views of the finished Little Cod installation on Nomadness . From the passage to the aft cabin:

Lying on the sole looking up (with the draft damper visible in the angled section):

And from the center of the pilothouse, showing the loading door on the end:

And, you see those little holes on the front corners of the top shelf surface? One of the major issues here is safety — not just keeping skin off the dangerously hot stove pipe, but keeping fast-moving knees off the sharp shelf corners, one hand attached to a handhold at all times whilst bounding along in a seaway, and careening bodies off the stove itself. Removing the original pole, which was necessary to allow pipe to pass through the deck in the only available location, complicated the problem; it’s a large enough cabin that one could get thrown off-balance easily without something solid to hold on to at every stage of a traverse from one point to another.

I have added a few more strategically-placed handholds around the boat, but the central fixture is a sort of “caging” of the stove made with 7/8″ stainless rail and Sea Dog stainless fittings .

The other huge issue, actually the biggest trade-off of this whole project, was the impact on engine and generator access. Massive sole panels have always lifted to the 90° position and locked in place with springs, but now they only make it to 60° and have to be held up manually… obviously inadequate, although the most-frequently serviced bits are still easy to reach (Racors, tank-selection valves, oil filters and dipsticks, the sticky shutoff rail on the injector pump that needs an occasional tickle, coolant caps, and so on). The raw-water impeller on the main engine, already a major pain to change, is now more so, and I shudder to think of having to change out the starter with this reduced clearance.

We’ll immediately fashion a couple of latches to support the access panels from the stove shelf, but if serious surgery is necessary, it will be necessary to unscrew the hinges and lift the units completely out (removing the stove as well if major gymnastics are going to be involved). Fortunately, it’s all serviceable by design.

Other than that detail, I am thoroughly delighted with this new life-support component in the technomadic escape pod. An efficient heat source is now readily harvestable, and even a small fire renders the cabin cozy without the Webasto roar or the shore-power requirements of an electric heater. And to anyone who Googled their way to this page whilst contemplating a stove for their boat… I can warmly recommend Andrew and his products. He exudes an old-fashioned sense of quality craftsmanship rarely seen these days, and this little stove of time-tested design is clearly going to outlast the captain of the ship.

Updates…

First, in the accessories department, a woodstove thermometer is essential. I use the Rutland one, which I got on Amazon, and it works well (though the Inferno is now getting better reviews):

Second, I finally got around to building the safety cage around the stove, and it has been a surprisingly pleasant addition to the boat… actually better than the post that had to be removed for the installation. I used standard 7/8″ stainless rail and fittings (I bought mine from Defender).

Third, it’s pretty easy to light with the normal methods (paper and little scraps of kindling), but if you want an effective shortcut, try these little fire-starters. Actually, I usually make my own with sawdust and melted wax, poured into egg cartons… but that’s a messy job and kind of a nuisance. The commercial ones work great, store forever, and save a lot of fiddling. The ones at that link should be broken into quarters, good for 144 fires.

The heavy stainless shelf took threads nicely, and where the angled braces meet the thinner heat shield they are bolted deeply into the supporting structure. I haven’t tested it with airborne body weight yet (and hope never to!) but it easily handles the dynamic loads of rough conditions and grabbing it hard to prevent a fall. The height was optimized for leaning, and the top rail will get decorative hitching some rainy night.

The latest additions (2012) are a Caframo Ecofan and a window! The fan is not as hearty an air-mover as a dedicated DC one, but who wants to cable and listen to another motor? This uses a thermoelectric element to generate power from the difference between the hot base and the relatively cool fins, and does a nice job of gently moving air across the stove and distributing it around a small boat cabin. I had considered mounting mine to one of the disks (with high-temp adhesive, given the enamel), but thought better of it… that’s precious horizontal surface most of the time and the fan lives in a foam nest off-season or underway.

As to the glass window… Andrew now offers a glass-front option when you buy one of these, but quoted me $400 for a retrofit. As much as I wanted one, that was a bit too rich on my current budget for a purely aesthetic item. This launched me on a lengthy quest, culminating at last in a source for custom pyroceramic shapes (not glass) that can take about 1300° F continuous and 10% overtemp for a short time… a healthy margin of error for a wood stove that will probably never see more than 750° F for more than a few YIKES moments as you frantically reduce the draft. It also survives thermal shock very well; here’s mine along with the Caframo fan:

It casts a beautiful warm light around the cabin, reflecting nicely off the overhead, and it’s great to see the fire without having to open the door! I still think it would be better to get the glass front option at the time you buy a new stove, but if you already have a Sardine , Little Cod , or Halibut … you can buy a piece of 3/16″ Neoceram, 6″ diameter, with pencil-grind edges from One Day Glass . (I was reselling them for a while, but don’t really need to be in the loop… gotta choose my battles!) It will pick up soot from the flames, but is easy to clean; just use a wad of wet newspaper and some of the ash from the firebox.

Follow-up (2013) note on fuel

When I had a domestic woodstove, I avoided burning driftwood because of the salt content… mixed with sticky creosote, it leaves a hygroscopic layer that absorbs moisture year-round and can quickly destroy cast iron or non-stainless stovepipe. Since this stove is enameled inside and out, I have not worried too much about that, though it is still not ideal.

Researching this recently for a discussion thread on Facebook, I turned up an interesting article (no longer online) from a chimney sweeping expert that advises against using one of my favorite fuels… mill ends. Clean, dry, neat-stacking, and often free, these cut-off chunks of dimensional lumber are really tempting, though I have noticed that they usually burn insanely hot. Now I know why (and they have other dangers as well, including salt and some nasty chemical).

Also, this classic book is worth having in your library: The Woodburner’s Encyclopedia (1976), usually pretty cheap on Amazon.

2017 Footnote

I sold the lovely Nomadness in 2016, and happily, the Little Cod did not fit the new owner’s cruising plans. I’m now installing it in a project shed near my new mobile digitizing lab, having swallowed the anchor.

Cheers, and stay warm! -Steve

29 Comments

damn, you cold water, monohull guys really DO like all the comforts of home :-)LOLOL!

OMG. I have become a monohull guy, haven’t I? Never saw that coming.

You may want to have someone who does fuel polishing to come and do a cleaning on your tanks. They treat your remaining fuel with biocide and cleaners and then pipe the fuel through filters to remove the gunk in the tank as well as the algae.

Then a treatment with biocide after that will keep the growth at bay.

Stumblingthunder

Sumblingthunder – yes, I am looking into that. Actually, I can polish onboard (two Racors and a system of valves with a transfer pump lets me move fuel among tanks, or even pickup in one and return to another while the engine is running), and I have been using biocide with the new stuff (the clean aft tank, which I just refilled yesterday). But that’s not as good as a proper tank cleaning… the question is whether or not such an extreme and expensive operation is necessary. I don’t want to wait to find out until the boat is getting thrashed in foul conditions, shaking it loose and clogging the filters…

Thanks for the comment!

Well its been a little over a month, hows the stove working out? Im looking into one for next year, and my biggest concern is that it can hold a fire overnight. Fatsco makes a tiny tot coal stove that I read an article on Good Old Boat that says it can be banked and they still have hot coals in the morning… whats your experience?

thanks deryk

Hi Deryk…

I haven’t yet tried a full overnight load… now doing the winter-moorage dance, making weekly trips to work on projects. The fires have been wonderful and the boat cozy… and it’s a great little incinerator. I’ll post when I have done some proper survival-heating!

Cheers, Steve

Just a thought that occurred regarding access below the stove. Would it work to cut that panel in half, then use a piano hinge on top to put it back together? That would allow you to fold it over itself, then open and should minimize your clearance issues. It should also be strong and fairly inobtrusive. I have brought brass hinge at Home Depot before at a reasonable price. Hope it works better than having to remove the hinges. Best of luck.

Lauren Neher

A few months have passed now, and there have been enough firings for me to have a better sense of performance. The other night it was subfreezing in the harbor, and I kept the stove going at about 450 degrees surface temp all evening. At bedtime, I stoked it full and minimized both intake and stack flow… 8 hours later when I stumbled to the galley for coffee, it was still too hot to rest my hand on (though I did not try to fire it up without kindling, as it was getting sunny).

In short, it works beautifully!

Hello, Just curious what kind of stove pipe you used? I am only finding 4 inch pipe that is for HVAC, and not for wood burning units. Thanks, Jon

Jon – I used the pipe provided by the Marinestove folks; here is the accessories page that details the pipe, shielding, bends, smoke heads, and related parts.

Cheers, and stay warm! Steve

Glad to see that your install is evolving to suit your needs. Its that element of customization that our spirited customers bring to their particular application which gives me an added boost in the shop every day. Did I mention Idaho Energy Logs to you for super long burn times? A Codger (someone who uses a Little Cod) down at Fisheries Supply in Seattle has reported incredible burn times. I need to try them. When we get into these long burn times it becomes all the more important that everyone heed the smoke/co2 alarm install recommendation. As you have witnessed boats can be tricky with air/chimney flow dynamics. Dorade vents and the like can throw a monkey wrench into the mix. Hence important to have an audible alarm alerting you to a drastic negative change in your flow dynamics. Topic shift. What do you do for hot water ? Any novel designs lurking for integrating the stove into the mix. Folks ask us from time to time and it would be a great option to be able to offer them.

Look forward to your Springtime assessment of life aboard with COD.

Cheers, Andrew / NSW

HI Andrew – great to hear from you! We just had our first burn of the season the other night, and it was quite pleasant to feel that pervasive warmth (so much nicer than the other heat sources aboard).

We picked up some very dense manufactured logs; don't know if they are Idaho. I will try them and let you know my impressions.

Thanks for the reminder on the smoke/CO2 sensors – that is in the plan for the shipnet, but I will get the hardware aboard now. Know of a combined model that is low power?

Hot water: I got rid of the demand water heater that came with the boat, installed with such a short stack that it didn't draft properly and spewed humidity/CO into the cabin. Aboard now is an Isotherm, which uses either AC (700W, well within Inverter range) or engine coolant loop. I don't have much experience with it yet, but would enjoy playing with a preheater coupled to the Cod.

Your stove always elicits admiring comments from visitors, even when just sitting there cold. I'm happy to have it aboard.

Cheers! Steve

Great job Steve! Great stove!.I am an Italian liveaboard, for 4 years in Venice (freezing cold and humid in winter) and always heating my days and night with an old wood burning stove. It makes the difference aboard. All my best and sincere compliments for your useful blog I am definitely linking your blog to mine. I row and sail to protect the water and invite people to a sustainable way of travelling and living.

Giacomo – Grazie mille!

Thank you Steve. E' un mio piacere.

I’m building a 200 sf meditation cabin on land, adobe brick. I live in northern New Mexico where worst winter temps rarely go below 0 degrees F. Will the Little Cod heat it adequately? I genuinely hope so, because I’d love to make this work out. I’m interested in the model that is red and has the glass fire door. Should we talk? Bob

Bob – I certainly think that it would work just fine in that space. The person you should contact is not me, however, but Andrew … the builder of the stoves. Sounds like a great application, and the red would be gorgeous.

How is the draft working on your little cod? I was considering going with a 4″ to 5″ adapter for a wider draft. Do you find the 4″ sufficient? Will it get a decent draft even when the setup is in “low profile” (minus the exterior chimney addition) mode?

Just want to know before I finalize my install plans, thanks!

Eric – I have never had any issues related to inadequate draft (if anything, it can be a little hard to turn down if you get it too fired up!). For this size box, I don’t see any advantage to expanding to a 5″ pipe… that’s getting into home-scale stove territory. As to the “low profile” mode, I have not experimented with that enough to answer you. I should! That is certainly how I would like it to be set up if I were in the mode of sailing/anchoring through winter months.

Cheers and stay warm! Steve

Well if you do get around to trying it, do let me know. I would much prefer to have it set up that way then have a tall chimney pipe sticking out.

I have no doubt we will both be quite warm this season 🙂

One last question actually. Do you know where they got the spacer hardware that got your pipe through the roof? I have been having a hard time finding one that will connect to 4″ pipe.

Thanks again!

Eric – you mean the deck iron? That is what the pipe connects to; no intermediate hardware. The heat-reflecting disc and hole liner were fabricated…

You can get the deck irons for 3″ or 4″ pipe from Andrew.

http://marinestove.com/Accessories.htm

It is a lovely looking stove! How is it working out, say when you’re away from civilization and other heating sources and the temperature is below freezing? Pros and cons?

Does it get much untidy in the cabin from handling and stacking the wood, or coal?

I am surprised it could still be warm after 8 hours. We have a stove in the kitchen of our house, and the wood burns down very quickly, I’d say less than 2 hours, and in the morning it’s chill.

Does the boat get dirty on the outside from the smoke?

I just fell in love with the neoceram/pyroceram window concept! We’ve got a Little Cod manufactured by the Enterprise-Fawcett foundry located in Sackville, NB, and instead of two round ports on the top surface its got one large rectangular port (the stove also came with a rectangular grilling rack that can be put in place of the solid rectangular port). I’m going to look into the possibility of getting a piece of neoceram cut to fit in place of the cast iron port but before I do I’d love to know more about your experience with your round pyroceram window. I think I’d personally go the neoceram route given the fact its used for cooktops and looks to be able to take more of a beating than pyroceram, a factor given the large area of our rectangular opening.

So, how’s your’s working out and what thickness of material did you go with (I’m assuming 3/16″)?

NICE JOB, looking at your page for ideas for an install like this for an airstream trailer, this is great!

Hi Johan, and sorry I took so long to reply! Just got through another winter…

I have been lazily using other heat sources at the dock (mostly), so I can’t report much on day-to-day operation over an extended period. From my casual use, however, I can make a few observations:

Untidy in the cabin: yes. Wood storage is kind of a nuisance, and makes me wish I had more stowage space. Mill ends are neat, but I believe I linked above to an article about their hazards (dang); harvested firewood will need to be mostly kept in a covered place outside with just the current inventory in the cabin.

Below freezing use: no problem. My boat is 44′ and this heats well.

Warm after 8 hours: not in my experience… I am willing to believe that it might be possible with practice, however, though that is pushing it (from my years with daily use of other wood stoves).

Dirty outside: I have not had a problem with that. The smoke head is on the extension pipe, and I tie the boom off to the other side.

Hello, Kai…

Glad you like the window idea! I did in fact go with neoceram… a 6-inch disc, 3/16″ thick. My only issue has been that with cooler/casual/decorative fires instead of serious hot ones, it blackens with soot. Fortunately, that is easy to clean… no need to buy the special stuff that is available; just use a crumpled wad of newspaper, moisten it, pick up some of the ash in the bottom of the stove, and give it a quick scrub followed by a wipedown with a paper towel.

Hi, I am interested in installing the “sardine” model wood stove in my first boat (Fisher37). I am concerned about sparks exiting from the chimney and setting my neighbours’ (or my own) sails on fire. Does the spark arrestor (smoke head) completely stop sparks or do you have to be very selective about your solid fuel. Cheers, Glenn

HI Glenn – I have never seen any issues with that except for a little sparkly feistiness during startup (but nothing that would be able to ignite nearby fuels). The Sardine is a sweet unit!

Leave a Reply Cancel reply

You must be logged in to post a comment.

You can be cozy and self-reliant with wood heat!

Sign up for occasional emails with wood stove tips and a heads up when we launch a sale.

We respect your email privacy

Thank you for subscribing!

You'll recieve ocassional emails with wood stove tips and a heads up when we launch a sale.

Build coziness, self-sufficiency and reliability into your boat

Want some guidance tell us more….

- Hidden Structure

- Do you have a stove picked out? Not yet Dwarf 3kW LITE Dwarf 3kW Standard Dwarf 4kW Dwarf 5kW Cookstove Combo Other

- What is the name of the stove?

- How big is your space? L x W x H (in feet)

- Hidden How cold does it get where you'll be spending the Winter? (in C or F?)

- How cold does it get where you'll be spending the Winter?

- Tell us more about your project, or ask us questions here.

- What's your name? * First Last

- What email address should we use to contact you? *

- Comments This field is for validation purposes and should be left unchanged.

Here’s How

Fill out the guidance form below to start the process with one of our wood stove advisors.

Prefer to explore options by yourself? Use our wood stove selector tool

Your advisor will help you determine all the parts you need for your specific installation.

Or use our chimney selector tool

Your advisor will compile everything you need and send an invoice directly to your inbox.

Know what you need? Shop Now ! Still have questions? We want to help !

Use our manuals & guides , videos & FAQ’s . Don’t worry, we are still with you. Reach out at any time for personalized help from one of our tiny wood stove gurus.

The Dwarf 3kw LITE Small Wood Stove

The Dwarf 3kw Small Wood Stove

The Dwarf 4kw Small Wood Stove

The Dwarf 5kw Small Wood Stove

We care about your project and have been where you are.

All of our support guides were first customers! One of our experienced guides will be in touch with you to get you warm and cozy as quickly as possible!

Elizabeth put a Dwarf 5kw in her skoolie home 4 years ago, and it’s keeping her and her family warm while she’s building their home in Northern Vermont.

Codylived in his Tiny House for almost 8 years, and he upgraded his wood stove to the Dwarf 4kw for a longer burn time during central Oregon winters.

Lucas installed a Tiny Wood Stove in his Tiny House, which he calls home if he’s not traveling the country in his van.

Heather got her Dwarf 4kw stove when she decided to settle down in Vermont in the RV she has been living in for the past 5 years.

Looking for More Information?

You can access our extensive Knowledge Base of articles all about wood heat in small spaces.

Contact Us at any point along your journey and we are happy to help!

Simplistic, functional and stunning Tiny House with a Tiny Wood Stove setup

They know what the DYI community demands...quality, affordability, good looks, user friendly website packed with relevant information, and great customer service.

Cozy Tiny House in Central Oregon with Tiny Wood Stove Setup

Sitting by the fire on snowy days with a cup of coffee and a book is a dream come true.

Isabelle's small footprint Tiny House

I wanted to add a dry heat to a small space where the humidity is often high

Joel and Sara’s unique and cozy Tiny House

It's so cozy to light a fire in the morning, and the stove puts off an impressive amount of heat.

Megan's Tiny House in North Carolina

I love my stove! Its so incredibly cozy. I get so excited to use it when the weather starts to turn.

A Writing Cabin in the Woods - Timberhomes VT

It is a beautiful, efficient stove, and the 'work' of keeping the fire going with its small logs is a mindful, lovely, satisfying task.

Ben's Tiny House

We lived in a 3300 sq ft home during the winter we were paying up to $500 a month to heat our home now I can heat my home with sticks my dog leaves lying around!

Michaels Japanese inspired Tiny House

Setting up the stove with a friend was a piece of angel food cake

Jay's Off-Grid Tiny House Writers Retreat

The Dwarf Stove works like a charm and heats my tiny home quickly and efficiently.

Brett and Natasha's Cozy Tiny Homestead

We have a craving for beauty and adventure and freedom-and if you're not loaded, you have to find creative ways of pulling that off.

Master Wood Worker's Exquisite Custom Tiny House

We live in a very expensive part of the world, and this lifestyle has afforded us financial freedom-the ability to live debt free.

An exceptional house truck with character

We live in a rainforest, so moisture control is very important, and the dry heat of a wood stove helps to dry out everything inside when it's pouring rain for days and days.

Vince's stunning Airstream renovation

It's honestly one of my favorite things we've done to our Airstream

Traveling with kids in a vintage trailer

There are so many reasons we enjoy the stove, from keeping us warm in incredibly cold climates, to drying all our snow gear in a matter of half an hour to re-heating my coffee on cold mornings and cuddling to a fire at night.

Vintage Airstream life with four kids

We love the ability to move our home to new locations in ideal temperatures, and the closeness it has cultivated for our family is the greatest part

The one-of-a-kind adventure rig

I loved the practicality of the stove. It's small, robust and easy to use.

The Kerr Family - Airstream living

Anyone who came into our Airstream commented on how it felt like a home with the wood stove.

The Roam To Root Skoolie – Interior Design Art with a Tiny Wood Stove

Having a Tiny Wood Stove in our tiny space offered such a tangible feeling of home on the road.

The Butter Bus – A Family Skoolie that combines Design with Comfort and Functionality

Customer service was excellent, the product is excellent, we recommend Tiny Wood Stove to everyone!

Skoolie living in Montana

Quality product and real person customer service.

Adventure family of four living in a skoolie

It was the best decision we made in our bus

Francesca and Nicholas and three dogs - Skoolie life

We love the idea of being able to pick up our home and move wherever we want or need to go.

Brent and Lindsey's Shuttle Bus Escape

The ability to have a warm flickering fire makes our space feel like home no matter where we are parked.

Ben and Meag's Debt-Free Happy Bus

We wanted our next step to be something of our own, unattached to any one location or schedule ...

Treb's Family of 5 Home Sweet Skoolie

We do life outside.

Zach & Annie's Nomadic Adventure Bus, Stormy

Hey, I could do that!

Full-time Vanlife Family with a Dwarf 3kw Lite

When we bought our van we knew we wanted a wood stove for so many reasons.

Kev's Alaskan Overland Sauna Gear Trailer

Jay and abby's off-grid adventure van.

There is a sense of home that comes with having a wood stove in your living space.

Gary's Yurt in Colorado

The stove itself is very high quality as are all the flue pipe components. Customer service was really great too!

The tiny wood stoves are attractive, compact and functional.

- Feb 10, 2022

Heating Our Sailboat: Diesel, Electricity or Wood, and What Kind?

Originally published in the C-Tow Newsletter

I’m not sure if you’ve noticed or not, but temperatures have started to drop again. The days are shorter, nights are longer and winter is slowly working its chilly tentacles into our daily lives. For those of us who boat year- round or live onboard, this means that we are already deep into the “what do we need to do to stay warm?” phase of the year.

Keeping warm on a boat is always a balance of many factors. The two big ones are what sources of heat are available and the second is what sources of power are available? Heaters on boats potentially use many different fuel sources from electricity, to diesel, to wood, to numerous other fossil fuels. Each has its positives and negatives. We have lived on three different sailboats and between them we used eight different sources of heat- three space heaters (two boat certified, one not), three different diesel heaters, a wood stove and a forced air heater which uses both electricity and diesel to create heat.

On our current boat we have a Webasto forced air heater, a space heater and a wood stove. Each of those heaters is great in its own way, but also has downfalls. For instance, the Webasto is great when we are at the dock. It is clean, quiet and sends warm air throughout the boat instead of just in the area where the heat is being created. It is quick and easy to turn on and off and safe and simple to run. However, it uses power, the heat from the heater quickly dissipates and it doesn’t do a fantastic job of drying out the boat. Many people absolutely love their forced air heaters and it is our preferred method of heat in the mornings or evenings when at a dock, as well as sometimes at anchor when we don’t have the time to have properly burn a wood fire. During the day while at the dock, we will also keep our space heater plugged in and running at whatever temperature is comfortable for us at the time. It is even easier to turn on and control than the forced air and it only uses one energy source instead of two for creating heat. However, if you don’t have a proper boat heater, space heaters can be extremely dangerous and in the event of a fire won’t be covered under your insurance. They can potentially fall over and cause fires, have overheating cords that cause fires, etc., and they are energy intensive, so they are not the best option for trying cut down on power bills, or for use when running off battery power.

Our third current source of heating on the boat is a wood fire place. This is my personal favourite for many reasons, including the fact that we live in a forest so it’s fairly easy to collect a fuel source. A wood fire doesn’t use any power, so even if we had dead batteries in the middle of nowhere we could stay warm, it dries out the boat quickly and releases ambient heat for hours afterwards. However, it takes a while to get the fire going, has to be stoked once every hour or two and it’s difficult to find an insurer that will insure a boat with a wood stove. Marinas also really don’t want people burning wood while at the dock. Many people also swear by their diesel wall heaters. Out of the three that we have had onboard our boats, only one of them worked as advertised. We found them difficult to light and potentially more dangerous than the other heating sources we have used. Many diesel wall heaters also need power to run their diesel pump and/ or fan, which means you are again depending on two sources of energy to keep warm. However, once they are lit and running correctly they create a lovely heat that nicely warms up a boat, burns efficiently for long periods and creates a lovely ambience.

Regardless of which type of heat you have onboard, being on the water during the winter is amazing when you can stay warm and different heating options work better for different boats and different people. It’s just a matter of figuring out which one will work best for you!

Recent Posts

How the Hole Thing Started | Pt 1 of Restoring Our Steel Boat

In Search of a Castle in SW Germany

Even Better than the Black Forest- Hiking the Palatine Mountains, Southern Germany

- Sails & Canvas

- Hull & Structure

- Maintenance

- Sailing Stories

- Sailing Tips

- Boat Reviews

- Book Reviews

- Boats for Sale

- Post a Boat for Sale

- The Dogwatch

- Subscriptions

- Back Issues

- Article Collections

- Free for Sailors

Select Page

Hot Stuff – DIY Sailboat Cabin Heater

Posted by Drew Frye | Interior , Projects

A simple, low-cost stovetop heater takes the edge off a chilly cabin.

F ew sailboats have a dedicated heating system for warming the cabin, something built-in and properly vented. This makes sense because a cabin heater with a flue can be a complicated, bulky, and expensive affair, and something that’s perhaps used only on occasion. So, when it’s cool and we decide to spend a night swinging on the hook, away from shorepower, many of us rely on portable heaters, usually propane.

A portable propane heater can do the trick, but these heaters also require ventilation as they consume oxygen and emit water vapor and carbon dioxide—and produce carbon monoxide as a byproduct of incomplete combustion. The rough-and-ready solution is to crack a window, but how wide? And then how much of the heat is lost?

There is another approach, a simple, non-bulky, low-cost solution that uses an existing onboard heat source: the stove.

The stove can’t tip and start a fire (unless something combustible falls on it, which can be prevented by maintaining a clear countertop). And although stoves generally don’t include an oxygen depletion sensor like you’d find on a portable heater, it’s easy to add a carbon monoxide monitor to the cabin.

All that’s needed to turn the stove into an effective, ventilated cabin heater is to provide a heat transfer surface and a way to funnel the exhaust outside the cabin. In fact, the ubiquitous Sig Marine (now Dickinson) Cozy Cabin heaters are not much more than this: a simple burner below an inverted-can heat transfer space, connected to a 1-inch stainless steel flue.

The stove aboard my boat is an Origo 2000, a non-pressurized alcohol stove fueled by denatured ethanol. I have turned it into an efficient, safe heater by using a retired, upside-down stainless steel soup pot as the heat transfer surface, resting atop the burner. Here’s how I did it.

- 1-inch ribbed duct hose, stainless. McMaster Carr 5241K13, $23.80 for 5 feet

- 4-quart stainless soup pot, thrift store or surplus

- Aluminum flashing

- 6 inches of 1-inch copper tubing

- (1) 1-inch copper 90-degree el

- Assorted small screws and two long cotter pins or nails

- Plywood or similar to build slider insert, or better, install the flue through cabin roof or bulkhead if you will use the heater often

Here Is How I Did It

First, I cut a 1-inch flue opening in the side of the pot with a hole saw, into which I inserted a 1-inch copper pipe stub. I attached the pipe by slotting to create tabs inside and out, which I secured with small bolts (blind rivets would have been a cleaner solution). Next, I added a 3-inch-high flashing skirt to accommodate and hold a pot on the top. The skirt also improves the seal around the flue exit.

For the flue, I attached 1-inch (ID) corrugated stainless steel duct to the copper stub on the pot, using a cotter pin driven through both. There is no need to seal this connection because the entire length is under slight suction. This flue must rise steadily, without low spots, and be 3-6 feet long.

The first season I used my heater, I kept the exhaust system simple. I cut a 3-inch-wide board to fit the aft end of the companionway slider, drilled a hole in the board, and passed the exhaust end of the flue through it. This way, I didn’t have to drill a hole in the boat.

But after realizing my heater worked, and that there was nothing to improve, I drilled a hole in the cockpit bulkhead for a permanent flue, which is just 3 inches of 1-inch copper pipe. There’s no need to insulate the pass-through because the flue temperature never exceeds 120° F. So far, rain has not blown in, and I could easily cap it if necessary. If the wind is from ahead or the beam as it would be sailing or at anchor, the draft is fine, but if there’s a strong wind from astern—for example in a marina—it can blow the draft into the cabin. I keep a 1-inch copper 90 el, which, when pointed up, solves that.

The burner on my Origo 2000 stove is rated at 7,000 Btu. Because my stovetop heater uses the same flue size as the 5,000-Btu Sig Marine Cozy Cabin heater, I decided to not exceed that combustion rate and keep the burner valve between 1⁄2 to 2⁄3 open. This will give a heat output of about 1,500 watts, enough to fully warm the cabin of my 24-foot boat in 10-20 minutes in cool to cold weather. If I can feel some of the exhaust backing out from under the inverted pot and into the cabin, I know the burner is firing too high.

To confirm the heater’s efficiency and safety, I took some measurements. I wanted to be sure the exhaust was leaving the cabin, so I scanned the surface and flue with an infrared thermometer. The pot surface reaches about 290-340° F. By the time the exhaust reaches the outlet, it has cooled to 80-120° F, proving high efficiency. I tested the air 1⁄2-inch below the lower rim of the pot, curious whether some of the exhaust was sneaking out under the bottom; the carbon dioxide level was barely above background, and the temperature never exceeded 200° F, confirming that essentially all of the exhaust goes up through the flue.

The purpose of the flashing rim and upper pot is to add heat transfer surface area and improve heating efficiency. Most of the time, the upper pot will be empty. But if I crank the burner to high and add two cups of water to the upper pot, the water will boil in 10-15 minutes. With the burner turned down—as it should be to warm the cabin—it will simmer soup, without burning or polluting the cabin with carbon dioxide.

Another advantage my vented, stovetop heater has over a portable propane heater is dryness. Burning propane (or alcohol) produces water vapor. Dry air is nearly as important as warm air to comfort because insulation remains more efficient. An unvented heater will raise the humidity 30-60 percent, making for a clammy cabin and causing condensation on the windows—not a problem with the vented heater.

This heater will work with stoves burning alcohol, propane, CNG, butane, and kerosene , as long as the firing rate is similar. The differences in combustion are small.

Although the heater is stable enough to be used underway, the pot on top is not. Also, I don’t leave the heater on while I sleep. It’s not designed for that, and I like sleeping under a thick quilt or in a warm sleeping bag. Nor do I leave it on while away from the boat. I run it from sundown, through the dinner hour, until ready for bed. I use a carbon monoxide monitor, and when cooking on the stove, I usually crack the companionway slider to evacuate water vapor.

Just running the Origo stove for one hour with the regulator half open and the cabin tightly closed, carbon dioxide reaches 15,000 ppm and carbon monoxide level reaches 100 ppm, both well into the danger zone. A cracked window will reduce this, but unless the window is open wide enough to admit considerable draft—rather defeating the purpose in cold weather—there remains serious risk of exceeding the limits for good health and clear thinking.

Keeping a Clear Head—DF

I value my brain cells and will not take risks with them; I’ve never been a fan of portable heaters.

Carbon dioxide concentrations over 1,500 ppm affect thinking and are universally considered cause for investigation and correction. Over 2,000 ppm is considered serious by health departments. Ten-thousand ppm is the threshold of serious problems with medium-term exposure (many hours to days), and both OSHA and NIOSH limit workplace exposure to 5,000 ppm.

I did a few simple calculations for my Corsair F-24. If I run an unvented portable propane heater at about 4,000 Btu/hour (what is required for a 45° F evening), assuming no ventilation other than combustion air replacement, carbon dioxide levels will reach 60,000 ppm within six hours, about the threshold of unconsciousness.

The Flowerpot Heater Myth—DF

The story goes like this: Place a flowerpot over a stove burner, and you have an effective, safe cabin heater for peanuts. Thermodynamics says otherwise, but I decided to test this myth anyway, because it would be great if it were true. Unfortunately, none of it is true, except for it being cheap.

Without regard to the efficacy of the flowerpot heater, using one can be dangerous. About 60 percent of glazed pots and 30 percent of unglazed pots I tested shattered violently at 400˚ F, throwing large, hot pieces of pot 2-5 feet. Only by limiting the temperature to 300˚ F (by keeping the flame quite low) was the shattering risk reduced to an acceptable nonviolent level. Considering that even Corningware is not stovetop safe, this should be obvious.

I used small (5- to 6-inch-diameter) and large (7- to 9-inch-diameter) clay flowerpots over a natural gas flame (bear in mind that propane is a little hotter, alcohol a little cooler). I measured pot temperatures and cooling rates, and I calculated radiant heat output of the naked flame and burner grate, and of the pot and burner grate. It’s important to note that when the pot is on the burner, any heat radiated by the naked flame, burner, and grate is blocked by the pot.

First, some basic physics. All heated materials absorb and then radiate heat. The amount they radiate is proportional to the fourth power of their temperature, as measured on an absolute scale, either Rankine or Kelvin. The hotter they are, the more they emit and the shorter the wavelength of the emissions.

Radiation is just one method of heat transfer; the others are conduction (the direct transfer of heat between solid objects in contact with one another, like how a hot pot heats the metal handle attached to it) and convection (the movement of heat energy within a gas or liquid, like how a heat source warms the air near it and that air begins to move and circulate). But it’s only radiant heat that is relevant to the question of whether the flowerpot heater offers a benefit. This is because for conductive heat to offer any benefit, you’d have to hold the pot. Convective heat isn’t very relevant either, because the balance of the heat in the flame would end up mixed in with the cabin air anyway.

A 7-inch flowerpot heated to 320˚ F emits about 150 watts (500 Btu) of thermal radiation. If the pot reaches 400˚ F, the amount of radiation emitted increases to about 370 watts, or about 1,100 Btu. In contrast, a naked propane flame is over 1,500˚ F and the burner grate will reach 400˚ to 800˚ F, depending on location. The radiation rate of the flame and grate alone is greater per unit area than that of the flowerpot, but the area of the flame and grate combo is much smaller. The result is that the pot offers little increase in the amount of heat radiated.

On the other hand, portable propane heaters, like the Mr. Heater line, heat a ceramic grid red hot (about 2-3 times hotter than the flowerpot on an absolute scale), and are thus 20-80 times more efficient at converting fuel energy into radiant heat. However, that does not mean they create more heat; the total Btu is fixed by the amount of fuel burned and cannot be increased.

It’s often said that the heated pot stores and releases heat over a longer period, thus keeping the cabin warm long after the stove is off. This sounds good but isn’t really accurate. First, a large pot will cool relatively quickly, smaller pots even faster. A 9-inch glazed flowerpot that starts at 300° F drops to 195° in five minutes, 130° in 10 minutes, and at a half an hour is at 85° F. The same pot starting at 450° F drops to 345° in five minutes, 280° in 10 minutes, and is at 110° in a half an hour. The hotter the pot, the faster the cooling.

Second, a large pot that weighs 3.2 pounds doesn’t store a lot of heat, a smaller pot even less. The specific heat of brick clay is .22 Btu/pound, and let’s say, for example, that a large pot cools from a high of 450˚ F to a low of 55˚ F overnight. The heat released by the pot is 278 Btu.

By comparison, let’s say the cabin sole, bulkheads, and furniture have all been heated to 70˚ F during a typical day, with the air temperature dropping quickly after sunset. The specific heat of pine (for example) is .66 Btu/pound. Assuming there are 500 pounds of furnishings, linings, flooring, and supplies in the cabin, with an average specific heat value equivalent to pine, the heat capacity of the cabin infrastructure is about 6,600 Btu. Additionally, the cabin furnishings will cool much more slowly, because at any given time, the temperature difference between the furnishings and the cabin air is very small. As noted above, hot objects cool far more rapidly than cooler ones. Thus, the clay pot represents only 4 percent of the heat holding capacity of the cabin as it cools during the evening (and this heat is given up within a few minutes). A rounding error at most.

Bottom Line: If it is merely cool, pull on a sweater. You can run the stove for a few minutes now and then, cooking a meal or making tea. This is less wasteful and just as effective as the flowerpot. If it is actually cold, install a proper heating system. The benefits of a flowerpot on the stove are at least an exaggeration, and more realistically, a dangerous myth.

About The Author

draws on his training as a chemical engineer and pastimes of climbing and sailing to solve boat problems. He cruises Chesapeake Bay and mid-Atlantic coast in his Corsair F-24 trimaran, Fast and Furry-ous, using its shoal draft to venture into less explored waters. He is most recently author of Rigging Modern Anchors.

Related Posts

The Case for Bondo

May 10, 2023

DIY Lazy-jacks: Mainsail Tamers

July 23, 2019

Vang/Preventer

July 25, 2019

Small-Scale Solar

March 1, 2019

Now on Newsstands

Join Our Mailing List

Get the best sailing news, boat project how-tos and more delivered to your inbox.

You have Successfully Subscribed!

How To Heat A Sailboat

Last Updated by

Daniel Wade

June 15, 2022

If you want to extend your boating season into the winter season, stay toasty warm, and dispel the dampness that can infiltrate your boat in cold weather, you need to get a reliable boat cabin heater.

Winter sailing is always a real challenge for most sailors given that the weather conditions are more adverse and calls for more preparedness. Fortunately, several types of boat cabin heaters can transform winter sailing into a more pleasant experience by keeping the interior of the sailboat warm and cozy. So if you do not want winter to spell the end of your sailing season, you’ve come to the right place: here’s how to heat a sailboat.

As we’ve noted, there are several ways to warm your cabin during the winter season or on a cold night. From hydronic systems, heating stoves, engine heaters, forced-air systems to reverse-cycle air condition systems and electric heaters, there are a lot of options for every budget. Although these systems may work differently, the basic idea is the same. They all either use fuel or another energy system to create heat that’s spread throughout the boat.

Let’s explore the most common ways to keep your sailboat warm during the cold season. But before going into that, let’s highlight some critical details.

Table of contents

How to Choose an Appropriate Boat Cabin Heater

The thermal outputs of these heating systems are generally measured in British Thermal Units (BTUs). The more BTUs a system produces, the warmer it can make your boat cabin. You should, however, remember that more BTUs will increase your electrical or fuel demands. In addition to BTUs, choosing the right heating system for your boat will depend largely on how well your boat is insulated, the kind of boat you have, how much time you spend sailing in cold weather, where you’re planning to sail the boat, and how much you’re willing to spend.

A Word of Warning

The dangers of poorly installing a heating system on your boat can never be underrated. Keep in mind that most of these systems will keep your cabin warm by burning oxygen, which can potentially fill the cabin with the deadly carbon monoxide that can quickly leave victims unconscious and may lead to death. As such, safety should be a priority.

How to Heat a Sailboat

Hydronic systems.

These systems are based on the same principles as household hot water heating systems. It revolves around a heated fluid running through a tube to radiators or fan units that warm the air. These tubes should run throughout the sailboat but the fan units or radiators can be divided based on the number of zones that the boat has.

In most cases, a hydronic system is smaller than a water heater but can also be used as a portable water heater for the boat, especially if you need hot water onboard. It’s generally installed in the boat’s engine room and can use a coolant to disperse the heat. It can use the fuel coming from the vessel’s main fuel tank or a special fuel tank.

The main advantage of using a hydronic system is that there is no moisture in the boat as there are no cold spots. An appropriate hydronic system should have a maximum output of 25,000 BTUs per hour while using 6 amps of power or 0.22 gallons of fuel.

Heating Stoves

Although they’ve been used for centuries, heating stoves remain one of the most popular ways to heat a sailboat. They can burn kerosene, diesel, and propane or even use solid fuels such as charcoal or wood. Some heating stove systems use the direct draft system whereby fresh air is pumped through a fan while others use the natural draft system whereby air is naturally pumped through the combustion process.

Either way, a heating stove should be located in the saloon to radiate heat and circulate hot air. They should be equipped with a damper to help in controlling the airflow, as well as an exhaust pipe to withdraw the exhaust gases arising from the combustion.

Keep in mind that most heating stoves do not use electricity. Nonetheless, a heating stove with an output ranging between 7,000 and 9,700 BTUs should be ideal, especially if it consumes about one pound of propane in about 5.5 hours.

Engine Heat

This revolves around using the engine’s heated coolant fluid to transfer the warmth into your boat’s cabin. The coolant lines should be designed to run from the engine into the heat exchanger. There should also be a fan that blows the cabin air into the heat exchanger so that the air is heated. The hot air can then be piped out into the boat’s interior through several hoses.

Using this system is advantageous in the sense that it’s quiet and depends on the engine’s closed-circuit cooling system, so it doesn’t require radiators or additional water pipes. Unfortunately, this system only works when the engine is running and can be quite expensive in terms of the extra engine maintenance and the fuel consumed.

Forced-Air Systems

This is a simple method that revolves around a heater burning fuel to heat air. This hot air is then forced through ducts via a series of vents to the boat’s cabin. Forced-air heaters are typically situated in engine rooms and generally have exhaust pipes to discharge combusted fuel.

The system can be turned on either manually or through its thermostat so that air and fuel are drawn into the combustion chamber to ignite the fuel and air blend under a controlled flame. This heated air is then forced into the duct and spread throughout the boat’s cabin.

Electric Heaters

This can be a perfect option if you occasionally go out on the water during cold days. Electric heaters function much like normal home ACs and usually run on 12-volt power. They’re typically mounted inside the cabin and run on electricity generated from the boat’s batteries that heat the coils. A fan draws air over the coils where it’s heated before another fan blows it into the boat’s interior.

The main downside of this system is that it has to use electricity, which means that you cannot venture very far from the shores. This is because you’ll need to recharge the batteries now and then and this will run them down very quickly.

Reverse-Cycle Air-Conditioning Systems

This works in the same way as a normal household heat pump by running in the reverse cycle. They’re typically very expensive but can be a great way to extend your sailing in the winter, especially if you want to circumnavigate the globe.

Another good option of heating your sailboat is heading south to sunny places such as Florida during winter. In most cases, the south is a bit warmer than the north during winter and you can keep going until you find the hotter climes of the south.

Installing a heating system is a great way of making the cold nights and winter season more pleasant and attractive. There are, of course, several ways to ensure that your boat is heated and warm, especially if you do not want to put the boat into storage and get back to the normal life on dry land just because it’s winter!

So if you still want to make winter a perfect sailing season , keep your cabin cozy with the above-described heating systems.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Upgrades

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

How To Choose The Right Sailing Instructor

August 16, 2023

Cost To Sail Around The World

May 16, 2023

Small Sailboat Sizes: A Complete Guide

October 30, 2022

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

Just added to your cart

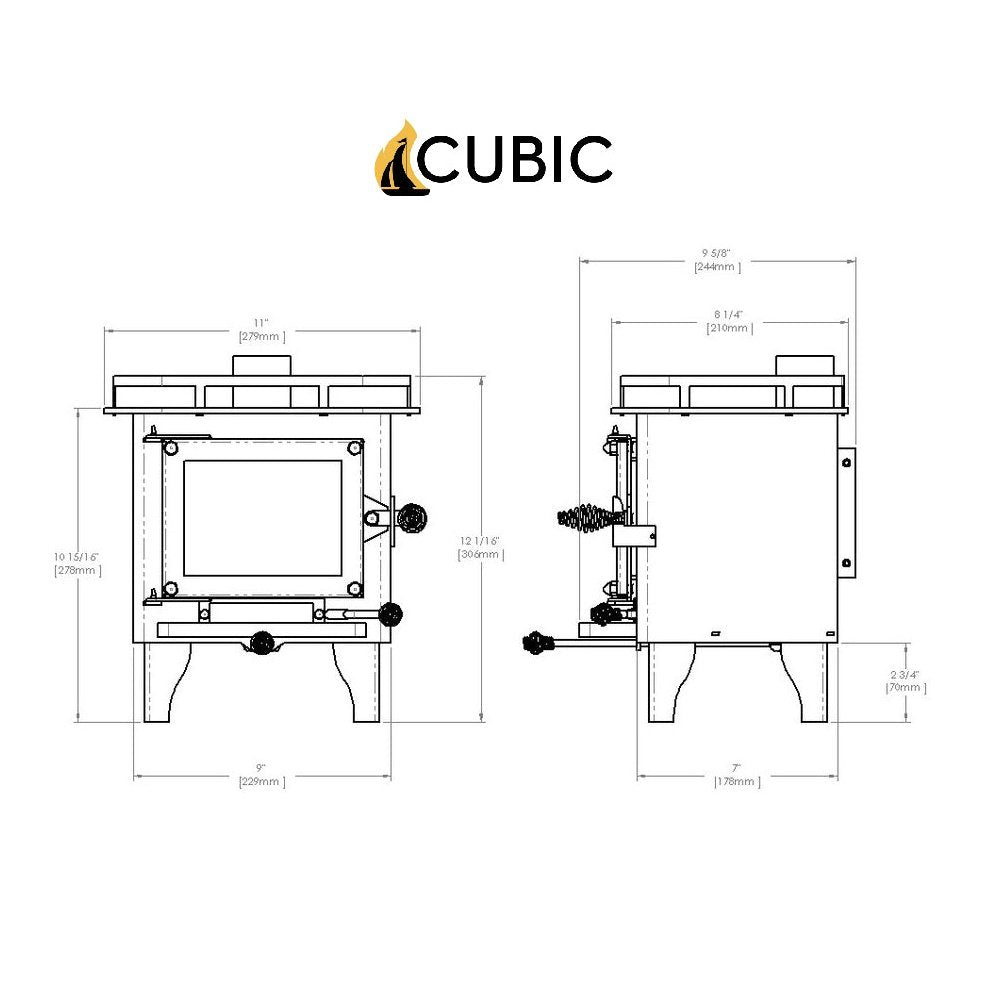

CB-1008 CUB Cubic Mini Wood Stove

Adding product to your cart

- Easy to install and easy to operate!

- Eco-friendly

- Produces very little smoke due to its secondary combustion system!

- Much safer than a diesel or propane cook stove!

- Removes humidity from the cabin.

- The rail is easily removable.

- Measures only 11" (Wide) x 12" (High) x 10.5" (Depth) ( 27.94 cm x 30.48 cm x 26.67 cm ).

- If you remove the rail, you have a cooking area of 5" ( 12.7 cm ) from the flue to the edge of the plate and 11" ( 27.94 cm ) side to side.

- Well seasoned hardwood and pressed logs are the best fuels to burn.

- Ideally the wood should be cut to 5 3/4" ( 14.60 cm ) long. It could be cut slightly longer. However 5 3/4" ( 14.60 cm ) allows for good airflow around the sides and it does not damage the insulation on the inside.

- 6000 BTU - 14, 000 BTU

- 1.75 - 4.1 KWh

- Requires a horizontal clearance of 20" ( 50.8 cm ) in all directions without shielding and a vertical clearance of 30" ( 76.2 cm ).

- Clearances reduced to 3" ( 7.62 cm ) when using proper mounting and shielding.

- The stove needs a complete flue system comprising of 3"(7.62 cm) flue pipe, 5"(12.7 cm) insulated pipe and exit kit NOT INCLUDED

- 3/16" laser cut steel top plate.

- 1/8" laser cut steel body.

- 1/2" thick vermiculate firebrick insulation.

- 3/16" thick self cleaning robax glass.

- Brass plated coil handles.

Related Products

- Cub Collection

- Share Share on Facebook

- Tweet Tweet on Twitter

- Pin it Pin on Pinterest

- Technical Data

- Operating Manual

- Warning Sheet

- description

Customer Reviews

FAILURE TO READ AND FOLLOW WARNINGS MAY RESULT IN SEVERE INJURY, FIRE AND/OR POSSIBLY DEATH.

- Never use liquid fuel or any other material containing fuel to start the fire Only use well seasoned hardwoods or pressed logs without wax or glue as a binder. Appropriate pressed logs should have a wood stove symbol on the packaging. Never use liquid fuels, pellets, or green wood.

- Never operate your stove without carbon monoxide and smoke detectors

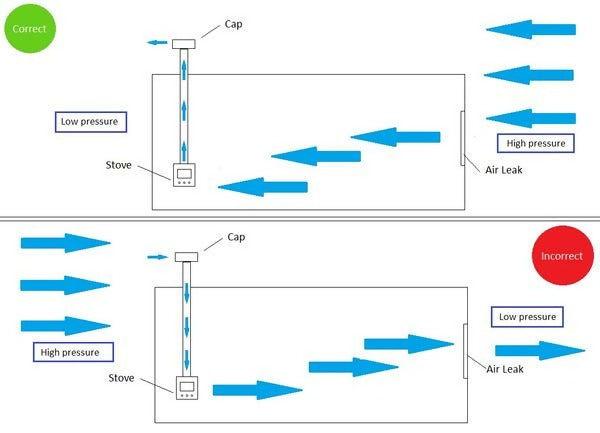

- Never open a window, hatch or door downwind of the stove

- Never use liquid fuel or any other material containing fuel to start the fire

- Do not operate your stove when the stove door is open

- Never leave your stove unattended when in use.

- Inspect and clean your flue pipe regularly. (weekly, until you determine your own cleaning schedule.)

- Keep fuel lamps, fuel containers, aerosol cans and any other combustibles at least 6 feet away from the stove

- Never use oil when cooking on the top of the stove

- Do not touch the surface of the stove when in use

- Never leave children and pets unattended when stove is in use

- Never use your stove in very rough seas

- Do not dry wet clothes directly on the stove

- Your appliance requires periodic maintenance and cleaning. Failure to maintain your appliance may lead to smoke spillage in your boat, cabin, or RV

- Never clean stove when your stove is hot

- Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or clothing ignition

- Due to high temperatures, the appliance should be located out of traffic and away from furniture and draperies

- Even after the appliance is out, the stove and the glass will remain hot for an extended period of time

- Under no circumstances should this appliance be modified

- Do not operate the appliance with the glass door removed, cracked or broken

- Do not strike or slam shut the appliance glass door

- Always allow a small amount of air to enter cabin, open a window, hatch or vent up wind from the stove to replace air consumed by the stove

- Nontoxic smoke will be emitted during the first hour of operation as the paint is curing. Open windows or hatches as required to vent cabin. Or you can cure the paint outdoors by attaching a couple sections of stove pipe to the stove and lighting it outside. To eliminate the odor can take up to 20 – 30 hours of burn time.

- Never operate the stove without the baffles being installed correctly.

Inspection and Maintenance

1. Remove ashes from previous use

2. Inspect the flu pipe and clean if necessary

3. Inspect the window and verify that it is free from cracks and breaks

4. Inspect the door gasket and verify that it is properly secured and free of damage

5. Clean the window

6. Close the secondary air intake by pushing the control handle to its furthest rear position

7. Open the primary air intake to its maximum setting by sliding the control handle to its furthest right position

8. Place small timber, paper or cardboard and a log inside the stove and light the fire using a long neck lighter or matches

9. After a few minutes begin to open the secondary control

10. When the stove has reaches its optimum temperature, add larger pieces of wood and adjust the primary and secondary controls to the desired heat output

11. To extinguish the fire, simply close both the primary and secondary air intakes

Tips and tricks

1. To clean the window, use commercially available stove window cleaner or simply dip a damp cloth in the ashes and rub on window. A scraper can also be used but this will reduce the lifespan of the window.

2. To keep the window clean during use, pull the embers towards the front of the stove and place the new burning material towards the rear of the combustion chamber

3. To prevent excessive amber accumulation, allow embers to burn and reduce before adding more wood

4. When starting the fire with pressed logs, cut small 1 inch slices until optimum temperature is reached

5. Pressed logs expand as they burn. Avoid positioning them in a way that can put pressure on the window as they expand

6. The gasket surrounding the door will become very brittle over time. Avoid touching it when operating or cleaning your wood stove

7. In certain high wind conditions, a growling sound may be heard. This is normal and does not represent any danger. Adjust the primary air intake to reduce or eliminate the sound

Returns are only accepted within 30 days of receiving your order. Returned items must be unused, in its original packaging, and protective film must not be removed from the stainless steel products. If a used item is returned, a stove for example: A 160.00$ refurbishing fee must be deducted from the refund along with a 60.00$ restocking fee.

How many BTU’s does the Cub produce?

6000 to 14000BTU’s.

How big is the Cub?

Width: 11” Height: 12” Depth: 10.5”

How much square footage will the Cub heat?

100 -200 square feet.

How much does the Cub weigh?

27 LBS or 12.25 KG.

What size logs fit into the Cub?

5 ¾” long logs, and it can take up to three or four 2”x4” pieces.

What size is the glass?

6 1/4" x 4 3/4" x 3/16" thick.

What size is the flue collar?

Outside diameter: 3”

Inside diameter: 2 7/8”

Thickness: 1/16”

What are the stoves made of?

They are constructed from laser cut steel plate 1/8” to 3/16” thick! Vermiculate insulation, 3/16” thick self-cleaning Robax glass and quality hardware.

Are the stoves certified?

They are not. Please do your due diligence before placing an order. (Check your local law and regulations.

Is there a warranty on the stove?

Overall wear and tear are not covered. For example: scratches, rusting, baffles, insulation, glass etc.

ALL DAMAGE REQUIRES A PHOTO SENT TO [email protected] .

We offer a warranty on the glass for the first 90 days of use.

If the stove body gets structurally damaged (excludes glass, wear and tear, insulation, intake mesh etc) and you would like to repair it, we will do so free of charge. However shipping will not be covered.

We will gladly help you out.

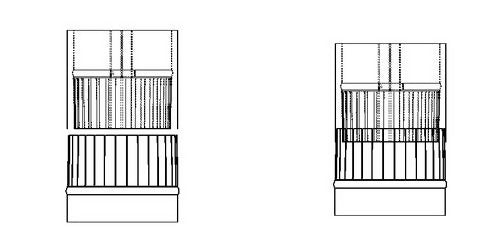

Can you remove the rail on top of the stoves?

You can, simply align the tabs under the top plate with the holes in the top plate with pliers and it will slide out with ease.

What kind of wood is best to use?

The best wood to burn is well seasoned hard woods. This will help you achieve the best heat output along with the longest clean burn. You can also use pressed wood logs. We do not recommend pellets.

What are the two screws inside the firebox for?

They hold the baffles in place by putting pressure on the top plate. The baffles allow the secondary combustion system to work efficiently.

How does the secondary combustion system work?

Simply put, it pulls air from underneath the stove and introduced in the fire box at the top. The hot air mixes with the smoke and ignites the gases which are created by the burning wood. This produces heat with energy, which would otherwise have been lost up in the flue pipe providing better efficiency.

How much clearance is needed between the stove and combustibles?

Clearances required are 20” in all directions lateral to the stove unless installed with one of our wall mounts. If no shielding is present then you need to provide 20” clearance to combustibles. A 30” Clearances applies to the top of the stove to the surface above. Under the stove should also be shielded and an air gap should be provided.

How long does it take to cure the paint and how do I do it?

Once this process is done the stove will not need to be cured again. The curing of the paint will require you to burn the stove at high heat for several hours. It can take 1-3 hours for the paint to stop smoking. It can then take 20-30 hours for the smell to stop being produced.

This can be done outdoors to prevent the space from being filled with smoke. You can bring the stove outdoors and attach 2-3 sections of pipe. Run it hot and this will evacuate the moisture out the paint. If no pipe is used, the stove will not get hot enough to adequately evacuate the moisture.

Where do the stoves draw their air from?

The air must be replaced since the stove is constantly consuming oxygen. The stove will draw air from the room. In most cases you can open a window or a hatch and that should be enough to replace the air. For spaces that do not have a window, or if you do not want to have a window open, you can use our wall mount with fresh air intake. This will bring air from outside to the area where the stove draws its air from.

Can I use it to cook?

Definitely. We have made many meals on our stoves. The Grizzly has a mini roaster which makes easy to cook virtually anything you want! We would suggest not to cook with oil or grease because it could be fire hazard.

How do I light the stove?