- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

- Skip to footer

Sailing Eurybia

Two Humans and a Dog sail Mexico on a Sea Maid Ketch

Making a Sail Pack: Improve on Sailrite’s Method (Part 1)

January 21, 2016 3 Comments

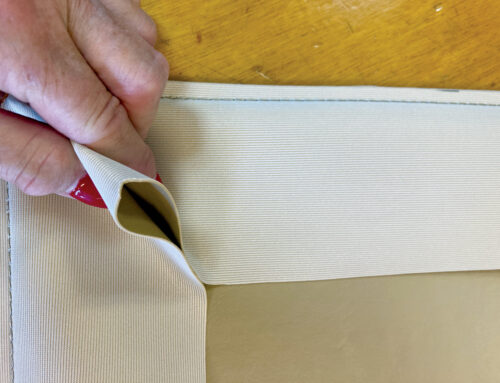

Sailrite now offers an attractive booklet on making a sail pack, along with a rectangular and a throated sail cover, which you can buy on their site here: SailRite’s Instructions for Three Sail Covers . I apologize for not making my notes apply to this booklet, but as I am out of the country I cannot easily receive this mailing. I much prefer downloadable instructions anyway.

At the time I made my Sail Pack they offered a stand-alone PDF for the Sail Pack for the same price. That older, downloadable guide (as well as careful measurements of your own boat!) will make a fine sail pack that will be a huge improvement on your current sail cover. However a few simple changes make it more robust and flexible for use on a cruising sailboat.

You may notice in my images that my sail pack is red on the port side and yellow on the starboard side. Normally I would have made it all one color, but I was using up my spare sunbrella and I only had enough in stock for one panel in each color. Because of the height of our sail stack, about 42”, I could not cut both panels out of one sheet as I could on our former, smaller boat. So I wasted a lot of material. Our boat colors are red and yellow (What could be more appropriate for Phoenix, or firebird, than fire colors!) so I used both colors together for a rather wild effect. (We are retired, but not retiring).

What is a Sail Pack?

What Changes to the Sail Pack might be Useful on Your boat?

The Sail Pack PDF is divided into 17 steps. For ease of understanding where and why I made changes I will discuss each change I made under the appropriate step.

Attachment between Mast Boot and Front end of Cover. Step 13. I chose to attach my mast boot with twist lock fasteners rather than zippers. I find them quicker to fasten and I didn’t like the idea of having half of the zipper exposed to sun all the time (although this can be helped with a deep enough placket). If your ratio of sails up to sails stowed is much lower than ours then you may wish for a more attractive closure that might be a little more difficult to fasten.

Aft closure. Sailrite does not provide a way to close off the aft end of the sail. I wanted to make sure no stray sun rays had a chance to make its way into the sail so I added a patch that wraps around the aft end of the cover. Mine just fastens with velcro which won’t last forever in the sun but is easy to replace. Anything else such as a webbing clip would possibly flail around and cause an issue. This can be done after the cover is finished.

Bottom closure type. Sailrite has twist lock fasteners on the bottom edge. I did not want a row of metal fasteners along the boom that would strike the boom or possibly a body part. However I did want to be able to remove the cover without taking down the sail. I decided on marine quality plastic buckles. Steps 9 and 10.

Whew – that’s a lot of words. Take a break and then visit Making a Sail Pack: Part 2 when you want to go step by step through Sailrite’s instructions with the differences I discussed above.

About the photos on this site

As I am currently in the Bahamas working on a house, and my boat is in Washington state, the pictures I am posting are during the first fitting after 95% completion. The final changes and adjustments to make it look crisp and pretty had not been completed; the lazy jacks were being tried for the first time; etc etc. I will try to remember to post updated pictures when we are back. Hey – it took me two years to write up what I did!

Share this:

- Click to share on Twitter (Opens in new window)

- Click to share on Facebook (Opens in new window)

- Click to share on WhatsApp (Opens in new window)

This site uses Akismet to reduce spam. Learn how your comment data is processed .

I’m looking at making a new sailcover for my Gulfstar 53 MS. I made the Mizzen & doing fine. Had the main done by a “canvas man” & have have multiple problems so after multiple repairs feel I need to remake completely. Problem I think is my main is so large ( boom 20 feet) and high (over the pilot’s house). My sails are also stiff & don’t flake well. New sails are very expensive & if ours work, well, use them! Like some of your ideas like the buckles instead of the twist fasteners. Our are always coming undone. … Read more »

I’m so glad it was useful! Depending on your webbing you may want to sew the two halves of the stack pack together (with a 2″ gap or so for rain water to get out) instead of using buckles. On the stack pack above, the buckles worked fine – the webbing was good, thick polyester webbing. On our current stack pack I ended up with nylon webbing which was far too slippery to hold the buckles well. We ended up sewing the two halves together using the webbing straps and although it is a little harder to put on, it’s … Read more »

Thanks! After sewing my sailpac for the first time I thought there could be some improvents. You nailed it! Thanks again.

Stay in touch - sign up for our newsletter for occasional news from Eurybia and her crew.

Your Boat Name:

Email address:

- Privacy Policy

“Live in the sunshine, Swim the sea, Drink the wild air” --Emerson

About This Site

SailingEurybia is a WordPress site. The theme is a version of the Genesis Sample Theme developed by Eurybia-Marie . ©2018

Make a Canvas Sailboat Cover - I Made It at TechShop

Introduction: Make a Canvas Sailboat Cover - I Made It at TechShop

This instructable will go through the process to sew up a canvas sailboat cover. You can use the Industrial Straight Stitch or Walking Foot sewing machine available at TechShop Detroit. This is a cover that is for a 14 foot Collegiate FJ Sailboat. I made it at TechShop www.techshop.ws

Step 1: Cut Up the Existing Cover

For this project I had an existing boat cover available to take apart and copy. This is actually a project to create 6 covers for the Penn State University Sailing Club. They sent me back an old cover they had that was falling apart to use to make the new covers. To start with I noted down where all the snaps and fasteners are in a notebook and tried to note as well as possible how the parts went together, especially in the areas that go around the shrouds and mast. After that I used a seamripper to separate all the pieces. For this design, all the small pieces are rectangular strips. There are really only 3 main pieces that need to have patterns made.

Step 2: Make Patterns

To make the patterns, I used scrim pattern material available from Sailrite. www.sailrite.com. They are a good source for canvas making supplies and have many good how to videos available on their website. To make the patterns, I laid the 3 large canvas pieces onto a piece of scrim material and traced them out using a sharpie marker. I traced roughly half an inch larger around the parts to account for the seams. You don't need to be super accurate here since you will be sewing and the final product will have some variation no matter how careful you are here. Just be sure not to go too small. Too small and it may not fit at all. A little too big and it will still seem like it fits just fine. I used the workspace at TechShop Detroit to lay everything out to trace the patterns. The longer piece of this cover is 15 feet long and quite awkward to work around in a small home workshop.

Step 3: Cut the Large Pieces

I bought a large quantity of 8oz/square yard, navy marine use canvas on Ebay. You can find material that is useful for this purpose there for a fraction of the price of name brand Sunbrella which is what a canvas show will use to make this for you. For a DIY project, heavy canvas will be fine and hold up for years. Lay the patterns onto the canvas and trace them out. For marking on navy colored canvas I found the best thing was a "jelly" white permanent ball point pen I found at Micheal's arts and crafts. I have had no luck trying to use a soapstone pen which is always the recommended tool for this. The generic canvas usually has a top and bottom with one side coated so you need to be careful putting your patterns down so that the coated side is facing inwards in your finished product. Cut out the pieces using a pair of high quality scissors from a sewing supply store. Your hands will thank you verses using a set of cheapy scissors from Walmart. The material cut will be cleaner and take longer to fray.

Step 4: Sew It Together

For sewing this you can use the Industrial Straight Stitch or Walking Foot machine available at TechShop. I used a home heavy duty single stitch machine. It is borderline adequate for this job. A normal home machine will not work. Use a quality 18-20 size needle or you will be bending or breaking the needle constantly. Sew the 3 main pieces together first. Use a technique after sewing the first time called "top stiching" which is where you hold the seam down and sew back over it again. From there I sewed the bow and shroud snap edges. These are rectangular pieecs that are folded in half so that they are too layer and then sewed to the appropriate seem on the main pieces. Cut all the rectangular pieces extra long by 7 or 8 inches. Sew them on 90% of the way. Stop and fold and cut the excess off the rectangular piece, sew that seam and then finish sewing it to the main piece. This allows you to be much less precise with cutting out the smaller pieces and also allows you to not be super accurate when sewing around curved seams. I sewed the 2 zipper flap edges on. These are also again rectangles that are folded in half so they are double layer and sewn to the main pieces. Sew the zipper on. I use YKK zippers available from sailrite. In this case a 2 foot long fixed length locking zipper. Pay attention to make sure your zipper will be able to zip after you install it. I try to keep stitching around an 1/8 to 1/4 inch from the edge. If you get any closer to the zipper it may be difficult to zip it later on. When sewing on the zipper side with the pull, sew 5 or 6 inches of the zipper, you can then bury the needle, lift up the foot and you can pass the zipper pull under the foot to the area you've sewn already and then sew the remainder of the zipper on. Sew the edge skirting on. These are very long pieces. The bow sections in this case are 9 feet by 9 inches and the stern sections are 12 feet by 9 inches. For each of these I made a sub assembly by flipping the bottom seam up and sewing it and then sewing the 2 sides over. Sew these onto the main pieces. They will all be a foot or so too long. Shorten as we did for the other smaller rectangular parts. Sew a bungee cord into the bottom skirt. I used 1/4 inch bungee cord from Sailrite for this with bungee hooks and stainless steel rings. To start with you can sew one continuous piece into the bottom of the skirt. I folded the bottom skirt up about 2 inches to make the pocket for the bungee. Sew some small reinforcement pieces into the rear corners. This will help keep the corners of the boat from wearing through. Sew a reinforcement under the middle of the cover. This will be used to hold the cover up using a halyard so that water will flow off of it and not puddle on the boat. Sew a small piece of webbing onto the top in this area to clip the halyard too. Sew a small piece of velcro to the strip going around the mast. At this point you are finished with sewing and it's time to finish the bungee and add snaps

Step 5: Finish the Bungee

You will need to split the bungee at the bow and the 2 side shrouds. At each of these use a bungee hook on one end and tie a bungee ring onto the other end. Leave some extra bungee in all of these areas for now. You can tie more tension into the rings after the next step.

Step 6: Add Snaps

Add snaps at each shroud, at the mast and above and below the zipper. I used snaps available from Sailrite along with the tool to attach them. The tool is a small metal die and tap that you use to smash them in like rivets. There is an inexpensive plier like tool available from West Marine to attach these. It doesn't work well, don't waste your money on it. Either use the hammer tool or spend a lot to get the sailrite tool that looks like a large set of vice grips. Put a snap on the skirt where the bungee exists each part of the skirt. Put the snap as close to the bungee as possible. This will prevent the bungee hooks and rings from sliding into the skirt. After this you can tie the bungee cord so there is more tension.

Step 7: Put It on the Boat and See How It Fits

Try out the cover by putting it on a boat. From here you can adjust the bungee cord tension in the skirt so it fits nice and snug. After that your finished.

Recommendations

All Things Pi Contest

Fix It Contest

Remake It - Autodesk Design & Make - Student Contest

- Pontoon Boats

- Personal Watercraft

- nauticalknowhow

- Nautical Knots

- Tools and Calculators

How to Make a Boat Cover

You should never underestimate the importance of a boat cover. A good boat cover will protect your boat from dirt and debris. Not to mention wear and tear from the sun and the rain. And of course it can protect from dings and scrapes as well. Not every cover needs to be a custom boat cover.

The problem is that many boats are oddly sized and shaped. There’s no real quality boat cover you can buy on the cheap to cover your boat. There are generic box covers you can buy at stores like Walmart. Walmart boat covers are not very high-quality, however. If you want a boat cover built to last, it’s not the best place to go. The boat covers Walmart offers are cheap for a reason.

If you head to a canvas shop to get one made for you, the price could cause you to do a double-take. On the low end of the scale you can expect to pay about $60 an hour for custom canvas boat covers. It’s also going to take about 9 hours’ worth of work at the minimum. That’s a $540 custom boat cover. At the high end of the scale you could be looking at over $1,300 for a mooring cover for a 24 foot Ski boat.

Why You Need to Make a Boat Cover

A boat cover is more than just an accessory. It’s a way of protecting your investment. Considering how much money a boat costs, you should want to do whatever you can to keep it in the best shape possible. When properly fitted, a boat cover does just that. Not every boater is convinced a boat cover is necessary. But take a look at exactly what a good quality boat cover can do.

- Protects against dust, dirt, and debris

- Prevents fading and damage from the sun’s harmful rays

- Keeps water and moisture away from your boat

- Prevents mold from forming

- Can keep animals from getting into your boat, and especially birds for making a mess on your boat

- It can also act as security for your boat by discouraging would-be vandals or thieves

The key to all of this is a well-fitted boat cover. Using any old boat cover won’t do. That’s why making your own boat cover to fit your boat specifically is one of the best things you can do.

How to Make Your Own Boat Cover

Making your own boat cover won’t just save you a lot of money. It will also ensure a perfect fit if it’s done the right way. The steps to make your own cover that are not as hard as you might think.

Measure the Boat: The first step towards making any decent boat cover is to know the exact size of your boat. Start by measuring the stern at its highest point. That could be the stern itself, or along any rails you may have. Write down the measurements on a rough sketch of your boat so that you’ll be able to refer to it later.

You can now move on to the windshield and measure the width and the height of its peak to the rub rail. After that measure the widest part of the bow and include the height of the rub rail if you have a railing there.

Get a full measurement from the bow rail to the stern rail. Make sure to cover every high point like railings, the windshield, and anything else. This ensures you’ll get a precise end to end measurement.

Double check all your measurements, just in case. When you record them remember that you don’t want a boat cover that fits too tight. Nor do you want a boat cover that’s too loose.

Buy Your Material: When most people talk about boat covers they use the word canvas. When you’re doing work making it, that’s called canvas work. In this instance, canvas doesn’t necessarily mean what you think. It doesn’t have to be that thick material that is literally canvas. Any kind of fabric or material can get the job done here if it’s light enough and strong enough.

One of the best places to get material for making a boat cover is from Sunbrella. Sunbrella sells a wide range of their own boat covers and bimini top. But they also supply the raw material that you can use to make your own boat cover.

Depending on your supplier, you could get Sunbrella acrylic fabric for around $24 per yard . This fabric is some of the best in the industry. It resists mold, water, and mildew. It also resists UV rays and it won’t stretch or shrink.

In order to sew your fabric, you need a special thread. This isn’t the kind of stuff you find at the local craft store. Use something called a V-69 polyester sailmaker thread. It’s high strength and it will not degrade in sunlight. It resists saltwater, mildew, and rough wear and tear. A 1,300 yard spool of it will cost you $13 .

A number 18 needle is recommended for sewing any three ounce to six ounce fabric. That includes the fabric that Sunbrella sells. You can get a pack of them pretty cheaply on Amazon. You want to make sure you have a number of spares because odds are you’ll break a few in your sewing machine.

If you’ve ever seen any professional tailors work, then you’ll know you need chalk. White chalk is good for marking fabric without permanently damaging it. Also, a solid pair of scissors to cut fabric will be very important. You may also want to pick up a stitch ripper to help fix any mistakes. Also, something called basting tape. Basting tape is a double-sided tape specifically used for canvas. It will allow you to precisely lineup and affix your fabric before sewing. This greatly cuts back on mistakes.

Cut Your Fabric: Now that you have everything you need and you can cut your fabric to size. Remember that you’re going to need some extra to stretch the cover around the sides of the boat. You also need room for ties to keep it tightly fit. Cut your panels to fit across the widest segments of the boat.

Stitch Your Panels: Overlap the fabric panels so they have about a 5/8 of an inch seam. Lay all the panels over your boat with this overlapping seam to ensure they fit. If the size and fit works out, you can use the basting tape to hold the seams where you’ve laid them out. At this point, you can use your sewing machine and stitch the fabric panels together.

Once you have the basic shape stitched together, place the stitched cover over the boat. Use your chalk to mark where you need to trim the edges down. Use your shears to cut it down to a reasonable size all the way around.

Set up Your Draw Cord: You should have left enough material around the edges to hem the edge. This will allow you to run a rope or draw cord around your cover.You’ll need to cut holes to allow the rope to come out. You should secure it with some large grommets. Alternately, you can fold the edges of the holes back and sew them to create a drawstring pocket.

Insert the Ropes: Make sure you have chosen a good quality, water resistant rope. Run it through the holes and leave a reasonable length for a drawstring at the end.

Cover the Boat: Now that everything is the right size and shape, send it over in the boat. If anything needs adjusting, now’s the time to do it.

Test the Ropes: At this point you can check to make sure you have enough rope so that you can pass it under your boat. kite securely to make sure it’s the way you want it to be. If everything looks good, you just made and secured your own boat cover.

Things to Remember

As you can see, the process of making a cover is not that hard. If you can use a sewing machine and measure materials, you can make a cover. The cost in materials versus what you have to pay for a custom cover is quite dramatic. You may have to hone your sewing skills first if you’re not comfortable sewing heavy material. Make sure you try a few scraps panels ahead of time to get the hang of it. Don’t panic if you break a needle, as it’s probably going to happen a few times.

My grandfather first took me fishing when I was too young to actually hold up a rod on my own. As an avid camper, hiker, and nature enthusiast I'm always looking for a new adventure.

Categories : nauticalknowhow

Urban Faria on September 6, 2020

Very, very interesting to me as I want to start a boat covering/canopy/cushion hobby as a retirement pastime.

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

More in nauticalknowhow

How to Tie a Boat to a Dock

How to Clean a Boat Cover

Everything You Need to Know About Your Boat’s Bilge Pump

4 Ways to Tie Your Boat Shoes

The People’s Poncho Review and Ratings

Oru Lake Kayak Review

What Is A Gunwale?

131 of the Best Hawaiian Boat Names

167 Patriotic Boat Names

About boatsafe.

Established in 1998, BoatSafe is your independent guide into the world of boating, fishing, and watersports. We provide expert insights and detailed guides to help you find products tailored to your needs and budget.

Contact Boatsafe

- Address: 4021 West Walnut Street. Rogers, AR 72756

- Phone: (479)339-4795

- Email: [email protected]

Site Navigation

- How We Test

- Corrections Policy

- Privacy Policy

- Terms & Conditions

- Editorial Policy

- Affiliate Disclosure

Our Reviews

All content is © Copyright 2024. All rights reserved.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

How Dangerous is Your Shore Power?

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

Gonytia Hot Knife Proves its Mettle

Where Winches Dare to Go

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Inside Practical Sailor

Sailboat Winter Covers: What to Look For

The post-pandemic rush to the sea has brought a whole new group of readers into the Practical Sailor family, so although many of you are already solved your winter cover cunundrum and may remember this post from years past, I felt it was a good time to help those new readers who are facing their first winter on the hard.

The onset of winter in the northern hemisphere brings with it that age-old problem: How best to protect the boat from snow and ice? Already boats on Lake Superior are buttoned up, and sailors as far south as the Chesapeake have already settled in for winter. While many powerboats choose shrink-wrapping over a more permanent solution, sailboats-with their masts stepped or unstepped-are perfectly suited for reusable custom, or semi-custom covers.

The topic of winter covers is worthy of a larger article all it’s own. A few years ago, seeking a snapshot view of the custom-cover options, we talked to Jim Welinski, co-owner of the family-run Shipshape Canvas shop ( www.shipshapecanvas.com ) in Duluth, Minn., where stored boats face some of the country’s harshest winters.

Most custom covers today are frameless, making them easier to stow and install than the excellent DIY frame-cover described on our website . In either case, a reusable cover will save money in the long haul. A robust, frameless winter cover for a Catalina 30 costs about $2,000 and can last eight to 15 years (with a re-stitching after about eight years), depending on how you treat it. Lighter-weight covers for less-harsh climates sell for just under $1,500 and can last about eight years. A single-season shrinkwrap job will cost $850. You do the math.

For cold-weather covers in dark northern climates, Welinski likes Top Gun, an acrylic-coated polyester that is tough, low-stretch, mildew-resistant, and abrasion resistant, just what is needed to stand up to fierce wind and cold. The material has two cons: It has a tough industrial finish, so a softer material is used to prevent chafe where the cover meets the hull, and it is not breathable, so good vents are essential.

For sunny climates with milder winters, Welinski recommends the UV-stable synthetic blend Weathermax, a breathable fabric that helps prevent mildew and condensation, but is not as strong and abrasion-resistant as Top Gun. Coated acrylics like Sunbrella are another option. Although not as tough or abrasion-resistant as Weathermax (see PS sailcover test , December 2011), Sunbrella’s 10-year warranty (pro-rated) against UV damage tops Weathermaxs five years.

Welinski also recommends using the UV-resistant thread Tenera in sunny places. Some canvas makers charge extra for Tenera, which carries a lifetime warranty, but others like Sailorstailor ( www.sailorstailor.com ) use it in all their products. Tenera’s downside, Welinski said, is that it can allow water to seep through needle holes when sewn into Top Gun, making it less desirable in this application.

For maximum lifespan, the devil is in the details. (Welinski abhors metal grommets, notorious points of chafe.) We recommend using a reputable local canvas maker that will measure your boat and help you fit the cover properly. All it takes is one fierce winter storm to shred a poorly fitted cover. Proper rope tension is critical.

If no local option exists, look for a company that has already fitted your model boat or has a template on file. Insist the company make adjustments for free within the first year. A high-quality cover should carry a four to five-year warranty for workmanship on top of the warranty for materials.

RELATED ARTICLES MORE FROM AUTHOR

11 comments.

That’s really nice post. I appreciate your skills, Thanks for sharing.

It’s great that you talked about sailboat’s winter covers and which one adapts to your weather. My dad’s thinking about getting a boat. He’s always wanted one, but since we live in a place where the temperature during the winter goes crazy, he’s worried about how to keep it well covered. That’s why I think this article is going to help him be prepared for it. Thanks for the information on how for cold weather, it’s important to find a cover to stand up to the fierce wind and coldness.

The PO of my Bristol 35.5 purchased a frame and cover from Fairclough in CT in around 2000. I bought the boat in 2013, and by 2018 the cover needed to be replaced. I called Fairclough, they not only had the measurements, they still had the original purchase order! They quoted me around $1,600 for new canvas, since the frame is still fine.

Darrell, a very timely article with the link to the PS sailcover test of 2011 just as informative. I bought a two-piece canvas tarp from that “reputable local canvas maker” (he is) in 2007 that weathered 14 seasons with only minor rips and tears until this past winter when the aft piece tore laterally from side to side. I went cheap on the frames, making my own wooden supports, very amateurish but adequate. From what you say, I seem to have gotten a goodly number of seasons for the $1200 I paid back then. The tarp is currently in for repairs. Fingers crossed that it will cover my 27-ft, mast-up sloop for a few more years here under the heavy falls of snow off southern Georgian Bay.

My boat partner and I invested in a Fairclough custom cover (mast up) in 2008 for our 89’ Sabre 34 and although we’ve had several restitchings done through the years, I feel we made the right decision both economically and environmentally. Suggestions: Wrap foam pipe insulators around any and all possible chafing points using 3M Scotch #893 filament tape. Having a zippered door to use off season is a big plus as well as the vents for circulation.

Rarely seen now are waxed cotton canvas covers. I worked for decades at a yacht club in Toronto and there were some covers that were over 30 years old. They were heavy but ridiculously durable. The only thing that seemed to kill them was poor storage. If left lying on a cradle all summer they would rot but if stored dry indoors were fine.

We have a 2001 Catalina 42 which came with Top Flight cover. We replaced the cover with a new one from Top Flight, and had additions for storing with the mast up. We modified the rear to accommodate our new Tower in a Box, which required four new zippers and flaps to wrap around the tower. So 17 seasons from the first cover, and the new one going on three. Beats having to buy plastic shrink wrap every year, and filling up our waste dumps with all that plastic, and at less expense. And Top Flight is very responsive when you need parts (new conduit or brackets) or to modify the existing cover for new things.

Here on Lake Erie we reuse shrink wrap I get 8yrs of use out of it Mast down with framework on a 42′ sailboat with 13.5′ beam. Some of powerboats are on 17 years of the same wrap a little tape goes along way.

I built a cover for my 43′ sloop using different color scrap strips of Sunbrella fabric. At the boatyard they call it the Circus tent. After the first season the wear points were pretty worn (Sunbrella doesn’t have much abrasion resistance.) I made wear patches from an old cut up dingy and they have held without any obvious wear for the next 3 seasons.

Thanks for this great article. I wrestled with this decision after buying my first sailboat in the summer of 2020 and realizing that I had to make a decision as winter approached and some leaky deck problems caused me to want to dry the boat out. I decided I wanted a full cover that would transmit some light, and allow me to work underneath all winter. I chose a system from Kover Klamps. I have not seen them mentioned in your articles. It is based on metal electrical conduit (EMT) and connectors. All told, it cost about $1600 for the frame and a tarp to go over it with a zip door, tie downs, and spares. I expect to get two or three years out of the tarp, and decades from the metal frame. It took a good bit of time to build the first time, and is not easy to move. But it is nice to work under during the winter, and allowed me to replace my two fixed and four opening portlights last winter. This year I will probably repair a piece of broken deck under a stanchion, and re-bed all of the other stanchions. In all, it has allowed me to work in relative comfort. It costs less than shrinkwrap and has less plastic waste. It costs and weighs less than canvas, and allows solar heating and lighting. I worry that it causes a lot of wind resistance due to how high I made it. It is scary to work under when the wind exceeds 25 knots!

Polyethylene plastic, standard sized tarps purchased over the counter and now online have covered my sailboats 23 – 33 ft for the past 40 years. For Upper Peninsula of Michigan and significant snow and wind, relative success with several tarps lasting five years tied over mast down and/or DIY wood frames. I recently purchased two 20’x16′ about $60 each for 16 mil.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Island Packet 370: What You Should Know | Boat Review

How To Make Starlink Better On Your Boat | Interview

Catalina 380: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Lazy Jack – stack pack sail covers

Click on the images in the gallery below for a step by step guide.

These names are some of the descriptions for a process of suspending sail covers.

I started making these Lazy Jack covers 20 years ago, as a progress/advance of the Lazy Jack rope system, designed to help flake a main sail as it is put away. The idea was to connect the rope to a sail cover to avoid having to remove the cover every time the boat was used. A few sailmakers and I had started making them by request; each one we made had small changes and became more functional as time went on. A sailmaker from Doyle Sails approached me one day and asked if he could copy some of my ideas, as he liked the way my covers worked. I agreed on the condition we swap ideas, as his shop was the only other manufacturer making improvements on each cover. We worked together for more than three years improving every one. As expected, others tried to copy our work with limited success.

Most of the original designs had removable front sections, which became annoying as many were blown, even lost, overboard. We then moved to either a front or side zip, and the excess fabric was tucked away on Velcro tabs inside the cover, as they are prepared for sailing.

We still make some this way. Most covers are tracked at the aft side of the mast. This makes them much more functional and user friendly, as there is only one zip to open. We even sometimes incorporate the zip slide into a continuous-loop pulley system. This way you can stand at the mast and open and close the bag. This is very handy when access to the aft of the boom is restricted by high Targas or are just too high to reach. We use Ronstan 19mm bearing pulleys for smoother deployment. There are different types; some can be screwed directly to the mast. The rope we use is a 6mm pre-stretch. At the bottom of the sail cover we run 12mm-1/2-inch PVC pipe between the two layers, through which the rope runs. This stops any friction on the continuous-loop system.

The covers we build are all Sunbrella acrylic canvas and are fully lined with mesh. This adds strength for the rope pull points. It stops abrasion from the corners of the sail when flaked and effectively stops the wearing to the Sunbrella and allows breathability. Breathability is very important to stop mold on the sail. As a further benefit, this adds a second layer where the batten is slid inside. The batten size we use is called Offshore 2 or 3, depending on how big the boat cover is. The No. 2 is 18mm by 8mm thick.

In addition, where the covers are mounted to the mast with track, sometimes we add a zip on one side to allow the owner access to the mast runners. The track mounting procedure is essential to add strength and stop corrosion between the track and the mast. We use 1mm VHB tape and Tef Gel on the screws to stop dissimilar metal corrosion between track and mast.

The covers are held to the boom with slugs. These are boom runners every 300mm, or 1 foot, apart. This adds a second tier of breathability and allows the release of water. Doing this also allows the reef points to sit where necessary without running them through the cover.

The main zip is a No. 15 Paskal zipper. Many of the original designs needed zip replacement regularly, mainly because of rough treatment. An upgrade was necessary for durability.

A zip on a sail cover is sitting flat, horizontal to the sun. Covering it is very important to eliminate UV degradation of the top zipper. Our solution is two-fold: First, the teeth are sewn inside each edge by 8mm (1/4 inch). Second, I make a molded acrylic cover flap, 60mm (2½ inches) wide. At the aft end, we add a 200mm zip extension. This is covered top and bottom to protect it from the elements. We do not use separating end zips on our sail covers. We use continuous zippers and again at the aft end. We use a canvas-to-canvas attachment version of the Stayput fastener. It is bolted right through the covering layers and next to the teeth on the zip. This stops the zipper from coming undone and acts as the stopper for the zip slide. PTFE lifetime thread is a must, and I have used it for 20 years on all my covers.

Early in my business I spent time analyzing failure points of covers. These are three-fold:

- Use lifetime PTFE thread.

- Where possible, fold edges and do not use binding.

- Properly cover all zips from UV.

In our local marinas, we have a very bad bird problem. Where most manufacturers carry the batten to the end of the cover, we stop them short of the end. We tailor the end of the cover down to a small opening. Doing this keeps the swallows and pigeons from nesting inside. In addition, we add extra eyelets in the gap between the track base and the start of the first slug, at the front of the boom. Lacing shock cord loosely between these eyelets stops bird access. If not used, birds usually find this access point quickly, which results in damage to cover and sail. We adapt the traditional look from a standard sail cover by placing a batten at the drop-off point. The drop-off point is the widest point of our sail covers. This method helps our sail covers shed rain. We believe most manufacturers create a water catcher by placing the batten too high.

I will be attending the 2017 MFA Conference in Jacksonville, and am always available if you have any questions. I am reachable on the Cover and Cushion Forum or by email. From time to time I will call to explain in detail.

David Elliott owns David’s Custom Trimmers in Brisbane, Australia.

Related Posts

Tailor-fitting a wrinkle-free front panel

How to eliminate vertical darts

Fabric-fitting perfect windshields

Advanced sewing tips and techniques

Advanced Textiles Association

1801 County B Rd W, Suite 100 Roseville, MN 55113

+1.651.222.2508 Textiles.org

Guides and tutorials for sea enthusiasts

[Tutorial] How to make a boat cover?

- Comfort on board , Bimini tops and biminis

![making a sailboat cover [Tutorial] How to make a boat cover?](https://captain-ocean.com/wp-content/uploads/2021/02/1A-scaled.jpg)

The boat cover protects your boat from the sun, dirt, and other attacks. If built in the right way, the bimini top guarantees a refreshed interior and shade during the blazing summer heat. Making your own bow or cockpit awning saves more money than buying a boat awning. Thus, this guide will describe how to make a boat cover , you will see that it is not as difficult as you might think.

How to make a boat cover: the materials to have

Before know how to make a boat cover , it is necessary to know the various tools required. The making of a boat cover will take you about a day.

What fabric to use for a boat cover?

Any type of material can do the trick, but it should be light and strong enough. We will often opt for a canvas. The Sunbrella canvas acrylic stands out, for example, in this area because of its high resistance to mold (you will no longer need to perform a mold cleaning on the boat awning), water and UV rays. In addition, this material does not stretch or shrink. But you can also opt for other models according to your needs. The important thing is that the canvas is waterproof, UV and mildew resistant and strong enough not to tear when the boat is sailing. Polyester is a material often used by awning manufacturers because it meets these specifications.

- See polyester canvas ideal for making a boat cover.

Materials for sewing the sun awning

To sew your fabric you need:

- a V-69 polyester sailboat yarn : very resistant to salt water, mold and rough wear, it allows to make a real sailboat sun awning or motor boat;

- a number 18 needle;

- white chalk to mark the fabric without damaging it;

- a strong pair of scissors to cut the fabric;

- a stitch seam ripper to help correct errors;

- basting tape to precisely align and affix your fabric before sewing. This greatly reduces errors;

- a sewing machine ;

- awning glue boat that is resistant to water and sun (be careful, to glue a sun awning on a boat, you must choose a glue for flexible PVC and not for rigid PVC).

Material to fix the sun awning on your boat

There are many ways to attach a sun awning to a boat. It all depends on your type of vessel: semi-rigid, sailboat, yacht, etc. You will then have to choose the most suitable solution for the layout of your boat. We have compiled a list of materials that you may find helpful:

- hooks for sun awning

- awning suction cups for inflatable boats

- stainless steel buttons

- a fixing kit for a sun awning

- a strong zipper for awning

How to make a boat cover step by step

Follow these different steps for your tailor-made boat cover:

Know the dimensions of your boat

La making a boat cover begins with the measurement of the sailboat. To do this, measure the stern at its highest point. Then you have to go to the windshield and measure the width and height of its crest to the friction rail. Next, measure the widest part of the arch and include the height of the friction rail if you have a railing.

Cut the sun awning

Now for make the awning of your boat , you can cut your fabric to the correct size. You're going to need a little more space to stretch the cover over the sides of the boat, and another space for ties to keep it snug. Cut your panels to fit the wider segments of the boat.

Create your panels

Overlap the fabric panels so that they have a seam of about 12 to 20 cm. Install all panels on your boat to ensure proper fit. If the size and fit are right, you can use the basting tape to hold the seams where you put them. You can sew the fabric panels together. Once you have the basic shape, place the sewn blanket on the sailboat. Use your chalk to mark the places where you need to cut the edges. Then use your scissors to reduce it to a reasonable size.

Install the drawstring

Enough material is needed around the edges to hem the edge. This will allow you to pass a rope or pull a cord around the awning. Holes have to be drilled to allow the rope to come out. Another trick is to fold up the edges of the holes and sew them together to create a drawstring pocket.

Insert the strings

This step involves threading the string through the holes and leaving a reasonable length for a drawstring at the end.

Cover the boat

This consists of sending the sun awning into the boat. If anything needs to be adjusted, now is the time to do it.

Test the strings

Finally, it is necessary to check that you have enough rope to be able to pass it under your boat in complete safety. If all is well, the manufacturing the sun awning for your boat coming to an end.

Our advice for the successful installation of a boat awning

In order to enjoy beautiful days on your sailboat or motor boat, here are some tips for making the sun awning.

The choice of the type of sun awning

Start by defining the type of boat cover you need. Your choice can be made on:

- un winter cover : which protects the boat during transport or when it is anchored;

- a road cover: which allows the boat to be completely closed by creating an additional room;

- a special awning for navigation protection (or cockpit cover ): it shelters the boat against the sun.

Measurement errors

In order to judiciously select the measurements of the bimini top, it is advisable to measure the width and length of the boat from side to side, whether semi-rigid or rigid. You simply have to subtract 5% from the measurement obtained to have the right width of your accessory. This will be used to ensure the installation of the mounting points and fixing for bimini top by suction cup or by awning glue. Record the measurements on a rough sketch of your boat for future reference.

Maintain and clean a boat cover

After having made an awning, the frequent question that arises is: how to maintain a boat cover? Essential, cleaning increases the lifespan of your awning or dodger for boat by removing dirt at regular intervals. For this, you must use a special sun awning cleaner.

- See an effective cleaner to keep your awning clean.

Especially avoid using a washing machine or pressure washer to clean it. Also, wait until the boat cover is dry before folding or storing it. This handling must then begin as soon as making a boat cover .

Finally, at the start of each season, it is recommended to waterproof your boat covers. For this, you must use a quality waterproofing product.

- See an effective waterproofing for a sun awning.

You now know how to make a boat cover. But if you'd rather buy one, there are plenty of sun awning manufacturers out there. You can opt for the Plastimo sailboat sun awning, the Osculati motorboat and sailboat sun awning or even those from Orange Marine. They have the advantage of saving you considerable time! To help you choose the best awning for your boat, we recommend that you read our guide to boat covers . You can also try to find used boat covers on Amazon , Ebay et Ticketmaster .

Find out more about boat covers, biminis and roofs:

[Tutorial] How to make a bimini for your boat?

How to make a roof for a sailboat?

[Tutorial] How to waterproof a boat cover?

MANUFACTURING: Which boat cover fabric to use?

You will also like :.

The best inexpensive sun awnings and biminis for boats

3 Cheap Ways to Make a DIY Frame for Your Boat Winter Cover

A boat frame is often used in conjunction with a winter cover to provide support and tension to the cover. However, buying a pre-made cover and frame can be expensive. Luckily, several cheap ways exist to make a DIY frame for your boat's winter cover.

One option is to use PVC pipes to create a frame for your boat cover. Another option is to use aluminum to create a sturdy, corrosion-free, and lightweight frame. If you prefer a traditional look, your third option is to use wood to create a boat cover support.

Ideally, you can also use metal as an alternative material to wood. It's more durable and requires little maintenance. However, it can have a higher initial cost than PVC, aluminum, or wood. If you've decided which material to go for, let's hop into how each of these frames is done, so you can get started.

- Building a boat cover frame from PVC pipes is popular due to its affordability and ease of customization, but it may not be as durable as other materials.

- Wood provides a traditional look and can be durable, but it requires more maintenance and may not be as long-lasting as other materials.

- Aluminum is lightweight and durable, but has higher costs (around $150–300) and is difficult to work with compared to other materials.

- Metal is a good alternative to wood as it is often more durable and long-lasting and can also be more cost-effective in the long run, but it has a higher upfront cost, around $200–$400.

On this page:

Building a cheap winter boat cover frame, making a diy frame using pvc pipes, building a diy boat cover frame using wood, using aluminum to craft a diy boat cover frame, utilizing metal in making a diy boat cover frame, guide on how to make a sailboat winter cover frame.

The table below shows the pros and cons, as well as the estimated costs of building a DIY winter boat cover frame using different materials:

Planning your DIY boat cover frame

Now, before you start building your DIY boat cover frame, you need to plan it out carefully to ensure a successful project. Here are some tips to help you plan your DIY boat cover frame:

Take accurate measurements

Measure the length, width, and height of your boat, and make a note of any protruding features, such as a mast. This will help you determine the dimensions of your boat cover frame.

Decide on the type of frame

You can build a wooden frame, or use PVC pipes and fittings to create a boat cover support system. The latter is a cheaper and easier option, and you can easily customize it to fit your boat's dimensions.

Determine the number of straps needed

To secure your boat cover, you will need to attach straps to the frame. Determine the number of straps you need based on the dimensions of your boat and the type of frame you are building. You may need to drill holes in the frame to attach the straps.

Choose the right tools

To build your DIY boat cover frame, you will need a few basic tools, such as a drill, screwdriver, and saw. Make sure you have all the necessary tools before you start your project.

For a step-by-step process on how to build a boat cover frame , you can read this article.

PVC pipes are a popular choice for building a DIY boat cover frame because they are affordable and easy to work with.

Materials needed to make A DIY frame using PVC pipes

To build a PVC boat cover frame, you will need PVC pipes, elbows, connectors, a tubing cutter, a drill, and clamps. The cost of each is stated in the table below:

Steps in making a DIY frame from PVC pipes

- First, measure your boat to determine the size of the frame you need.

- Cut the PVC pipes to the appropriate length using a tubing cutter.

- Use elbows and connectors to join the pipes together to create the frame.

- Drill holes in the pipes where you want to attach the cover.

- Use clamps and bungee cords to secure the cover to the frame.

Advantages and disadvantages of a DIY frame made of PVCs

Advantages of using pvc pipes.

One of the advantages of using PVC pipes is that they are flexible and can be easily bent to fit the shape of your boat. This flexibility allows you to customize the frame to fit your specific boat shape and size, providing a snug fit and maximum protection from the elements.

Another advantage of using PVC pipes is that they are resistant to corrosion and rust, making them ideal for use in marine environments. They are also easy to clean and maintain, making them a cost-effective solution for building a boat cover frame.

Disadvantages of using PVC pipes

While there are several advantages to using PVC pipes for a DIY boat cover frame, there are also some disadvantages to consider:

Durability : While PVC pipes are resistant to corrosion and rust, they are not as strong as metal or wood. In harsh weather conditions, the pipes may bend or break, which can compromise the structural integrity of the frame and reduce its effectiveness in protecting your boat.

Weight : PVC pipes are lightweight, which can be an advantage when it comes to assembly and disassembly of the frame. However, this lightweight nature may also make the frame less stable in windy conditions and may require additional anchoring or weighting down.

Aesthetics : PVC pipes may not look as aesthetically pleasing as other materials such as metal or wood. This may be a consideration if you want your boat cover frame to blend in with the surrounding environment or if you have strict aesthetic requirements.

Environmental impact : PVC is a type of plastic that is not biodegradable and can take hundreds of years to decompose. This means that if the pipes are not disposed of properly, they can contribute to environmental pollution.

If you prefer a more traditional look, you can build a DIY boat cover frame using wood.

Materials needed in building a DIY frame using wood

To build a wooden boat cover frame, you will need a saw, a hacksaw, a drill, screws, and plywood. The cost of materials is stated in the table below:

Steps in building a DIY frame out of woods

- Measure your boat to determine the size of the frame you need.

- Cut the wooden boards to the appropriate length using a saw.

- Use a hacksaw to cut holes where you want to attach the cover.

- Join the boards together to create the frame using screws.

- Attach the cover to the frame using clamps and bungee cords.

Pros and cons of using wood as a boat cover frame

Pros of using wood.

- Cost-effective : Building a wooden boat cover frame is typically more affordable than purchasing a pre-made frame.

- Customizable : You can customize the size and shape of the frame to fit your specific boat and needs.

- Durable : A well-constructed wooden frame can be sturdy and reliable, providing long-lasting protection for your boat.

- Easy to repair : If any part of the frame becomes damaged, it can be easily repaired or replaced with new wood.

Cons of using wood

- Time-consuming : Building a wooden boat cover frame can be a time-consuming process, especially if you're not experienced with woodworking.

- Requires tools : You will need access to certain tools such as a saw, drill, and hacksaw to build the frame, which may require an additional investment if you don't already own them.

- Requires regular maintenance : Wood can be susceptible to rot and damage from moisture, so you might need to take steps to maintain the frame and prevent these issues.

- Limited lifespan : While a well-maintained wooden frame can last for several years, it may not be as long-lasting as other materials such as metal or PVC.

Aluminum is a lightweight and durable material that is resistant to corrosion and rust, making it a popular choice for boat covers.

What's the Best Material for Winter Boat Covers?

Materials required to build an aluminum boat cover frame.

To build an aluminum boat cover frame, you will need to purchase aluminum tubing, connectors, and fasteners. You will also need a saw, a drill, and a measuring tape to cut and assemble the frame. The cost of each one can be found in the table:

Steps to craft a DIY frame from aluminum

- Cut the aluminum pipes to the appropriate length using a tubing cutter.

- Join the pipes together to create the frame using screws.

Benefits and drawbacks of using aluminum as a DIY boat cover frame

Benefits of using aluminum.

- Lightweight : Aluminum is a lightweight material, which makes it easy to handle and install.

- Durable : Aluminum is resistant to corrosion and rust, which means that it will last longer than other materials such as wood or PVC.

- Low maintenance : Aluminum requires minimal maintenance, making it a convenient option for those who want to spend less time maintaining their boat cover frame.

Drawbacks of using aluminum

- Cost : Aluminum is typically more expensive than other materials such as wood or PVC, which may make it a less affordable option for some people.

- Difficult to cut and assemble : Aluminum can be more difficult to cut and assemble than other materials, especially if you don't have experience working with metal.

- Limited lifespan : While aluminum is durable, it may not be as long-lasting as other materials such as steel or PVC.

- Conducts heat : Aluminum can conduct heat, which means that it may become hot to the touch in direct sunlight.

If you're looking for an alternative to wood, metal can be a great option for building a DIY boat cover frame. Metal is often more durable and long-lasting than wood, and it can also be more cost-effective in the long run since it requires less maintenance and is less likely to need repairs or replacements.

Materials for building a DIY frame using metal

To build a metal boat cover frame, you will need a saw, a drill, screws, metal tubing, metal connectors, and a metal cutting blade. The cost of materials is stated in the table below:

Steps in building a DIY frame using metal

- Cut the metal tubing to the appropriate length using a metal cutting blade.

- Use metal connectors to join the tubing together to create the frame.

- Use screws to secure the connectors and tubing together.

Pros and cons of using metal as a boat cover frame

Pros of using metal.

- Durable : Metal is often more durable and long-lasting than wood, making it a great option for a boat cover frame.

- Low maintenance : Metal requires less maintenance than wood and is less likely to need repairs or replacements.

- Easy to repair : If any part of the frame becomes damaged, it can be easily repaired or replaced with new metal tubing.

Cons of using metal

- Higher upfront cost : Building a metal boat cover frame can be more expensive upfront than building a wooden frame.

- Requires tools : You will need access to certain tools such as a saw, drill, and metal cutting blade to build the frame, which may require an additional investment if you don't already own them.

- Heavier : Metal is generally heavier than wood, which may make it more difficult to transport and maneuver.

- May develop rust : Depending on the type of metal you use and how well you maintain the frame, it may be susceptible to rust and corrosion over time.

A sailboat winter cover frame is a structure that is used to support a winter cover over a sailboat during the cold months of the year. The frame is typically made of metal or PVC pipes and is designed to fit the specific dimensions and shape of the sailboat.

The winter cover is then draped over the frame and secured in place to protect the boat from snow, ice, and other harsh weather conditions. The frame provides support for the cover and helps prevent it from sagging or collapsing under the weight of snow and ice.

How to Winterize Your Sailboat Cheaper & Quicker

To make a sailboat winter cover frame, you will need the following materials:

- Metal or PVC pipes (1-2 inches in diameter)

- Pipe connectors (T-joints, elbow joints, etc.)

- Measuring tape

- Hacksaw or pipe cutter

- Drill and screws (if using metal pipes)

- Rope or bungee cords

- Winter cover

Step-by-step process to create a sailboat winter cover frame

Measure the length, width, and height of your sailboat to determine the size of the frame you will need.

Cut the metal or PVC pipes to the appropriate lengths using a hacksaw or pipe cutter.

Assemble the pipes and connectors to create the frame. Use T-joints to connect the pipes that will form the base of the frame and elbow joints to create the corners.

If using metal pipes, drill holes in the connectors and attach the pipes using screws to secure them in place.

Once the frame is assembled, drape the winter cover over it and secure it in place using rope or bungee cords.

Make sure the cover is tight and secure, with no sagging or gaps that could allow snow or ice to accumulate on the boat.

Check the frame and cover periodically throughout the winter to ensure they remain secure and in good condition.

Leave a comment

You may also like, the complete checklist for winterizing your boat (free pdf).

More than twenty years ago, when I bought my first boat, I didn't have a clue about a lot of things. As the first sailing season was winding down, a friend asked me …

How to Winterize Your Sailboat Cheaper & Quicker

The Average Cost to Shrink Wrap a Boat (per foot)

The Real Cost to Winterize Your Boat on a Budget

Pros and Cons of Shrink Wrapping a Boat - Worth It?

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

25 Homemade Boat Cover Ideas You Can DIY Easily

Boats are expensive, so it’s worth the effort of making sure yours is properly protected when you’re not using it, but unfortunately, even the covers themselves don’t come cheap. However, there is a solution that will save you some money, and that’s to make your own.

For anyone who wants to have a go, we’ve scoured the internet to see what other people have been trying – and as a result, here’s a selection of the best DIY boat cover plans you’ll be able to copy yourself.

Table of Contents

1. How to Make a Boat Cover – Boatsafe.com

2. how to make a power boat cover, 3. do-it-yourself: fashioning canvas covers for your boat – passagemaker, 4. best diy boat cover support system, 5. making a new boat cover for my skerry – christinedemerchant.com, 6. boat cover diy, 7. how to make a powerboat cover – sailrite, 8. how to make sunbrella dinghy cover to protect pvc from sun uv, 9. how to make a boat cover – doityourself.com, 10. easy cheap boat cover support frame diy, 11. homemade boat cover support system – ourrecipesforsuccess.com, 12. diy boat cover, 13. make a canvas sailboat cover – i made it at techshop: 7 steps – instructables, 14. how to fix a boat cover that gets filled with water, 15. diy: small boat cover frame – bound to journal, 16. how to build a tarp frame for a boat, 17. diy canvas repair tips – boating magazine, 18. how to make a trailerable boat cover, 19. how to make a homemade pontoon boat cover support system, 20. cheap and easy boat cover frame – how to diy, 21. diy tarpaulin for your yacht: a low-cost alternative, 22. make your own winter boat cover, 23. secret tarp hacks, 24. our diy boat cover – adventures on the club, 25. diy retractable boat cover, plenty of great options for diy boat covers.

As this post explains, providing your boat with a good-quality cover is important for protecting it, but since boats come in all shapes and sizes, it can be hard to find the right one for a reasonable price. The alternative is to make one yourself, and this blog post tells you all about how to do it, with details on the materials you’ll need as well as a step-by-step guide to completing the project. A well-written post and well worth a look.

Check More Details

The written introduction to this video tutorial tells you it will teach you how to make a custom cover for your powerboat, and if that’s what you need, it’s recommended watching. At well over an hour, it’s a long video, but that means it goes into plenty of detail to help ensure your project is successful and the cover you make is a perfect fit for your boat.

Sewing is a handy skill for any seafarer to be acquainted with – for example, you never know when you might need to make running repairs to your sails while on the ocean. However, even on dry land, those skills can be put to use if you want to make your own DIY cover to keep your boat safe. It’s not such a difficult job, and with the right equipment and a bit of determination, anyone can do it – and this blog post will teach you how.

If you want a cover for your boat, you may also need a support system to hold it in place. That’s what this tutorial is about because in it, this YouTuber shows us how he built a frame to hold the cover for his Jon boat . The frame is made of PVC pipes, and the tarp itself cost only $20 – so as you can imagine, the whole setup was extremely inexpensive. And if you want something similar, it should be easy enough to copy his plan at home.

In this post, this blogger tells us about how he designed and made a new cover for his skerry. As he explains, his previous tarps only lasted around two seasons each, and this time, he wanted something a bit more durable. He gives us a clear description of what he did and also provides plenty of photos, so if you need something like this, why not have a go at making one yourself?

This video gives you a basic method for making a cover for your boat using just a simple tarp. If you only have a small boat and don’t need elaborate solutions, sometimes it’s best not to overcomplicate things – and if that sounds like the kind of project you want to try, this is the video for you.

The homemade cover protecting the powerboat in the photo looks highly professional, and as the post promises, you’ll also find plenty of helpful tips, techniques and step-by-step instructions for making a snug version just like it for your boat. It even includes a video showing how to do it, making this a great resource for anyone interesting in making a DIY boat cover.

In this video, you’ll learn how to make a cover to protect a dingy from UV damage. Dinghies are not usually made of particularly UV-resistant material, so it’s important to cover them up. Buying a cover can cost around $800, but with this plan, you can make one for much less, saving you a whole lot of cash.

There are several benefits of making a cover for your boat rather than buying one, as this blog points out. You can save money, and importantly, one you make yourself will probably be a much better fit for your boat. It’s also not that difficult to do, and this post takes you through how to complete the job in just eight simple steps.

Like #4, this video tutorial shows you how to build a cover frame that will help keep rainwater out of your Jon boat . It’s another simple and inexpensive design based on PVC piping, offering an easy and affordable way to protect your boat from the elements.

This is another plan for a boat cover support, but this one is for something a little more substantial since the frame is made of metal. That means there’s a little bit of welding involved, but if that doesn’t put you off, it’s an easy enough job – so why not see if you can replicate it at home?

Here we learn about a simple technique for fitting a tarp to a duck-hunting boat. As this YouTuber explains, just covering his boat with a tarp would result in a sag in the middle where water would collect. His solution was to rig up a DIY frame to create a ridge – and his idea worked perfectly. Check out his video and see what you think.

Making a DIY cover for a sailboat is among the more challenging types to attempt, but with the right plan, it’s far from impossible. This tutorial takes you through how to do it in a clear and logical order, and it also provides you with plenty of photos for reference. Plans from this site are always high quality, and this is another one that doesn’t disappoint.

For anyone fed up with water pooling on their boat cover when it rains, this is a useful video to watch – because in it, you’ll find out about a super-simple but highly efficient solution to your problem. Sometimes the simplest ideas are best, and this video is the proof. Great job, we enjoyed this one!

This blog recounts a common problem that many boat owners probably recognize – namely, water pooling inside the boat after snow or rain due to the cover sagging. The simple solution is to build a frame that allows the water to run off over the side – and the included video teaches you how to make one.

The YouTuber in this video seems to have quite the dry sense of humor, but he also has lots of great ideas about how to build a frame for your boat cover . So if you want to find out how to do it – and you don’t mind a joke or two along the way – this is a video you should enjoy.

If you already have an old boat canvas and don’t want to spend the money on buying a new one, you can DIY one – or you can DIY-repair the one you already have. The second option can save you both time and money and can also allow you to put off buying a new one for at least couple of years. Sound like something you might be interested in trying? Then give this post a read!

This is a long and detailed video from the same people who made #2, and just like that offering, it’s a high-quality tutorial. This one teaches you how to make a trailerable boat cover, and if that’s what you need, there are few better videos online for you to watch.

This is another plan that teaches you how to make a boat cover frame, this time for a pontoon boat . As the blogger explains, there’s nothing more frustrating than coming back to your boat and finding it full of water or even critters – and this plan will show you how to prevent that from happening.

The cover frame this video teaches you how to make is intended for bass boats , but as we are told, it would be easy to modify the design to fit other types of boat too. It’s an easy and cheap method that anyone can copy, and it works perfectly too – so what are you waiting for?

When it comes to storing your yacht through the winter, there are lots of factors to consider, but in almost all cases, you’ll need a reliable tarp to protect it. This blog post talks in detail about the best options for boat storage available to you and tells you how and why this blogger decided to make a DIY version – so if you’re facing similar decisions, it’s well worth checking out.

Here’s one more video from the same people who made the videos in #2 and #18 – and just like those tutorials, this one is long and full of invaluable information. This upload is about making a winter boat cover, and if that’s what you’re interested in, you’d do well to watch this video all the way through.

This video is another one from the YouTuber who gave us #16, and in this video, he shares all the tips and tricks about tarping boats that he’s accumulated through years of experience. That means it doesn’t give you a specific plan to follow, but it does give you plenty of useful info – which makes it worth a look before you start planning how to make a DIY tarp or boat cover of your own.

The retractable cover this YouTuber made for his dive boat cost only around $125, making it an effective yet affordable solution to the problem of protecting his vessel. As he explains, without the cover, his boat was constantly being filled with pollen, pine needles and a whole lot more, but by utilizing the trees around where he stored the boat, he was able to rig up a DIY solution. It works perfectly too, so check it out if you think you might want to copy some of his ideas.

As you can see, whichever type of vessel you own, there are plenty of great plans for making a DIY boat cover that will help keep your boat protected and safe while also saving you a bit of money.

We’ve enjoyed collecting these plans for you, so we hope you’ve enjoyed watching and reading them too. And above all, we hope we’ve helped you find the ideas you needed to get started on a DIY boat cover of your own.

Related posts:

- 18 Homemade Wood Boat Plans You Can DIY Easily

- 18 Homemade Boat Trailer Plans You Can DIY Easily

- 17 Homemade Boat Lift Plans You Can DIY Easily

- 17 Homemade Boat Motors Plans You Can DIY Easily

3 thoughts on “25 Homemade Boat Cover Ideas You Can DIY Easily”

The bottom of my 2000 Logic is coming apart at the bottom of the transom. I heard there was an issue with this. What are mr recourses ?

Budget is another consideration and the good thing is that I’ll find an affordable and effective one. Mypontoon still needs protection even if it’s in storage.

thanks for the useful information. pontoon boat covers to protect it from the harmful rays of the sun which contain UV rays. budget and quality of cover are very important

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

- Share full article

Advertisement

Supported by

critics notebook

Kristen Stewart Uses Naked Dressing to Make a Point

Her press tour for “Love Lies Bleeding” was something to see.

By Vanessa Friedman

Even in the context of the current pantsless trend prevalent on the runway and in some celebrity circles, as well as the vogue for thematic dressing at movie openings, Kristen Stewart’s looks during her press tour for “ Love Lies Bleeding ” have stood out. Rarely has an actress been so unapologetically, gloriously undressed.

Ms. Stewart and her stylist, Tara Swennen, have taken the film’s carnality and covert politics and translated them for the promotional panopticon, forcing anybody watching to confront their own preconceptions about women’s bodies, their sexuality and exactly what empowerment means, while at the same time undermining the whole circus of branded celebrity dressing.

That’s a lot of subtext under very little — clothing, that is. But it was adroitly managed and awfully entertaining to see.

Margot Robbie had fun dressing à la Barbie during her “Barbie” press tour ; Zendaya captured eyeballs and social media during her “Dune: Part Two” camera calls dressed in sci-fi-themed Mugler, Givenchy and Alaïa; and the cast of “Godzilla Minus One” walked the Oscar red carpet in matching lizard-heel footwear. But with her “Love Lies Bleeding” appearances, Ms. Stewart took the concept of character cosplay to a new, more pointed level.

It started in Berlin back in February, when Ms. Stewart shed her shirt for the film’s European premiere, wearing a very short Chanel couture patchwork miniskirt, matching blazer and knit bralet. (She is a Chanel ambassador.) She raised the ante with a controversial Rolling Stone cover in which she wore only a Nike tank top and a jockstrap.

And when she showed up for the film’s Los Angeles premiere in only a “skirts, who needs ’em?” Bettter bodysuit, cut very high on the thigh, with sheer black tights, a black blazer and black stilettos, it was clear that such choices were not mere flukes but a conscious strategy.

As it happens, the motto of Bettter, a label that repurposes men’s suiting for women, is “empower rather than overpower.” Which, given the movie being celebrated, a queer film noir set in a small town in 1980s New Mexico and, as one reviewer wrote, a “ deconstruction of cinematic hypermasculinity ,” is pretty much on the nose.

It was when the promotional juggernaut reached New York, though, that Ms. Stewart really showed her hand. As well as other body parts, in an abbreviated black mini worn with a mesh bra, garter belt-’n’-stockings and a leather blazer for “Late Night With Seth Meyers” and a sheer Monot draped chain halter for “The Late Show With Stephen Colbert.” Paparazzi caught her exiting her building in tiny cream-colored knit hot pants and a bra worn under a khaki shirt, with stilettos, and then in athletic Chanel micro shorts and matching leg warmers. Again with heels.

The clothes were like a dare to the watching world, a refusal to cater to pretty-girls-in-pretty-dresses gender expectations and a good-natured riposte to the idea that provocation is an invitation. An “I see your judgment and raise you one” piece of fashion politics.

In so orchestrating her outfits, Ms. Stewart, who looked as if she was enjoying herself quite a lot, thank you, demonstrated just how much can be said on the pseudo red carpet even without an E! host asking the point of what she was wearing. You really couldn’t miss her point. After all, she wasn’t exactly covering it up.

Vanessa Friedman has been the fashion director and chief fashion critic for The Times since 2014. More about Vanessa Friedman

Explore Our Style Coverage

The latest in fashion, trends, love and more..

Win Friends and Hustle People: Ashwin Deshmukh, the managing partner of Superiority Burger, built a reputation as a nightlife impresario by burning close friends, new acquaintances, big corporations, local bars and even his subletter.

Vintage Clothing Buffs: Laverne Cox, Anna Sui and other enthusiasts shop at the Sturbridge Show, a gold mine for people who buy and wear exquisite old things.

Making a Scene on the Radio: In an era of podcasts and influencers, Montez Press Radio is reviving the D.I.Y. spirit of a bygone downtown New York City.

Dressing the Part: Women in media recently had a chance to browse and buy clothes owned by the trailblazing TV news anchor Barbara Walters .

Portland Soho House: The status-conscious social club has landed in the Pacific Northwest’s crunchiest city. Some locals wonder why .

The Next Birkin: Priscila Alexandre Spring, a bag designer and creative director of leather goods at Hermès, has the fun and formidable challenge of creating a new icon .

- CBSSports.com

- Fanatics Sportsbook

- CBS Sports Home

- NCAA Tournament

- W. Tournament

- Champions League

- Motor Sports

- High School

- Horse Racing

Men's Brackets

Women's Brackets

Fantasy Baseball

Fantasy football, football pick'em, college pick'em, fantasy basketball, fantasy hockey, franchise games, 24/7 sports news network.

- CBS Sports Golazo Network

- March Madness Live

- PGA Tour on CBS

- UEFA Champions League

- UEFA Europa League

- Italian Serie A

- Watch CBS Sports Network

- TV Shows & Listings

The Early Edge

A Daily SportsLine Betting Podcast

With the First Pick

NFL Draft is coming up!

- Podcasts Home

- Eye On College Basketball