7 Best 3D Printed Boats in 2023

Written by: 3DSourced

February 20, 2024

3D printed boats have seen a lot of developments in recent years, and have yielded some impressive results, overall showing a lot of promise for exciting and environmentally friendly vessels.

In this guide I’ll be showing you some of my favorite examples of companies making huge waves in 3D printing boat technology, everything from upcoming luxury liners to customizable sloops made from recycled materials.

Solvit3D – 3D Printed Boat Parts

Top 3d printed boats projects, 3dirigo – the largest 3d printed boat from the university of maine.

- Company: University of Maine

- Price: Not For Sale

- Where to Learn more: 3Dirigo and Guinness World Records Official Site

University of Maine Composites Center research team broke three Guinness World Records with 3Dirigo, the largest 3D printed boat to date , weighing 2.2 tonnes and measuring 7.62 meters.

Created in just 72 hours with a plastic-wood cellulose mix, this milestone was achieved using a 3D printer developed in partnership with Ingersoll Machine Tools. This wasn’t the only example of such a partnership, as the University of Maine’s Advanced Structures department has since worked in military equipment development in 2022 .

Capable of additive and precise subtractive manufacturing, the printer can prototype for defense, civil, and infrastructural applications. With a capacity to print objects up to 100 ft long, 22ft wide, 10ft high, and a rate of 500 pounds per hour, UMaine has found itself a real game changer.

The same 3D printer drew the attention of the US Army Combat Capabilities Development Command for deployable shelter systems production, with the UMaine presenting a 3D printed army communication shelter alongside 3Dirigo.

Tanaruz Boats – Customized 3D Printed Boats

- Company: Tanaruz

- Price: $16,000+ (Price varies depending on model and customization options)

- Where to Buy: Tanaruz Boats

One of the biggest advantages of 3D printed boats is customization. Dutch start-up company Tanaruz offers fully personalizable 3D printed boats made to order via their app.

From this app you can select the model, shape, color, and even engine type to get exactly the boat you’d like using additive manufacturing to maximize efficiency and precision.

With the cost-cutting advantage of 3D printing, the Tanaruz team makes their boats very affordable for most customers without sacrificing quality. For just a €500 (~$556) deposit, you can reserve your dream 3D printed boat.

Pegasus 88m – The Carbon-Neutral Superyacht

- Designer: Jozef Forakis

- Price: Not Yet Released

- Where to Learn More: Pegasus 88m

The Pegasus 88m is a 3D printed ‘superyacht’ that even in 2023 only really exists on paper, but is still well worth talking about. Designed as a completely carbon neutral 3D printed luxury boat, it was conceived with nature a the forefront of designer Jozef Forakis’ mind.

Solar powered panels power electrolyzers that convert seawater into hydrogen, which is then stored in long-term tanks for later fueling. This means the Pegasus 88m can harness the power of the ocean for theoretically unlimited power, removing the need for fossil fuels entirely.

The Pegasus 88m is designed to look like a cloud as it floats on the water. Using a clever mirrored design, the idea is for the frame to reflect the ocean and great the illusion of invisibility.

While still a work-in-progress, we recommend keeping an eye on this exciting, albeit likely unaffordable, 3D printed boat project.

Hydra – The World’s First 3D Printed Aquatic Drone

- Company: AI Seer Marine

- Learn More: Naval News

UAE company AI Seer Marine specializes in unmanned boats, and they unveiled the final version of their 3D printed vessel, Hydra, in 2023.

The 5 meter (~16’ 5’’) Hydra is effectively a proof-of-concept that additive manufacturing can play a key role in boat construction. AI Seer Marine uses the lightweight nature of 3D printed frames and parts to enhance speed and efficiency as well as cutting costs along the way.

The project has been underway for some time, and only recently been unveiled as close to finished. You can see the first active trials of the Hydra’s prototype below.

Those of you familiar with boats will recognize the Hydra employs a ‘stealth’ shape, intended for use in naval ISR (intelligence, surveillance, and reconnaissance) missions. This means that it likely won’t be available for sale, but it’s still a cool project to keep an eye on.

Autonomous Ferry – 3D Printed Ferry For Paris

- Companies: Roboat, Holland Shipyard, and Sequana Développement

- Learn More: Holland Shipyard

The collaborative effort of innovation partners Roboat, Holland Shipyard, and Sequana Développement has born this concept for the autonomous ferry designed to carry tourists and athletes along the Seine river in Paris in preparation for the 2024 olympics.

The model builds on previous Roboat builds of self-sailing and docking passenger vessels in Amsterdam, as you can see in the video below.

Offering visitors and locals alike a unique and futuristic experience in small-scale aquatic travel, the three companies hope this ferry will showcase enough features to be a great step in the future of 3D printed autonomous boats, possibly even replacing bridges.

The companies are being quite secretive about their 3D printed ferry so far, but Olympics-goers are looking forward to experiencing the boat for themselves. And at a planned size of 9 x 3.9m (29.5 x 12.7′), it promises to be the world’s largest 3D printed autonomous ferry ever made.

Impacd Boats – Sustainable 3D Printed Sloops

- Company: Impacd Boats

- Price: $40,000+

- Where to Buy: Impacd Boats

3D printed boats don’t have to be big and flashy, they can also be simple but effective crafts to handle small-scale sailing. Impacd Boats offers customizable 3D printed sloops as comfortable and easy-to-ride boats for any lazy river fan to buy and enjoy.

The main mission is tackling carbon emissions and making a positive impact on environmental health. Their boats are 3D printed using recycled waste material, and even the decorative items included with their models are from sustainable origins.

Impacd Boats took inspiration from data taken from TU Deflt research into sustainability in aquatic travel , and developed a greener, more environmentally friendly construction process using additive manufacturing. Each boat even features an energy-efficient motor that is as silent as they are safe.

They only have two models available at the moment, but are working on the technology to release different kinds of sloop at affordable prices for anyone who wants to discover how to sail guilt-free.

- Designers: Alexander and Roman Schmidt

- Price: $1 – $16,694.85

- Where to Buy: Solvit3D

3D printed boats are exciting, but 3D printed boat parts are making just as much of a difference. Solvit3D specializes in 3D printed objects like boat parts and decorations, offering over 60 different examples from light fixtures to compass covers and even custom switch panels.

Brothers Alexander and Roman founded Solvit3D after discovering additive manufacturing’s ability to create complex geometrical shapes with speed and ease. The parts are light and highly customizable for any taste or any boat.

While they don’t 3D print entire boats, Solvit3D should be bookmarked by any sailing enthusiast for practical replacement parts and aesthetic upgrades at very reasonable prices.

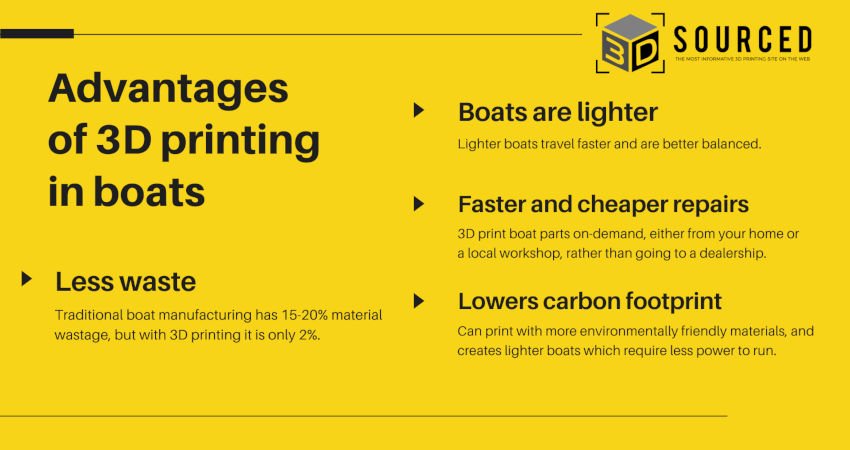

Advantages of 3D Printing in Boats

3D printed boats have several key advantages including less waste, lighter weight, quicker and cheaper repairs, and lower carbon footprint.

Reduced Waste

Traditional subtractive boat production, such as CNC milling, results in a lot more waste than 3D printing , making additive manufacturing a more cost-effective and sustainable process.

It’s also worth mentioning that some woods used in boat production are unsustainably, and sometimes even illegally, sourced , further adding to the need for alternative materials and manufacturing methods.

Research in the sustainability measures in boatbuilding carried out in 2021 shows some frankly alarming statistics . Only 55% of companies have a sustainable sourcing policy for their building materials, while 40% claim to not have the budget to research or implement more environmentally friendly construction methods.

Lighter and Better Balanced Boats

Additive manufacturing yields boats that are lighter, faster, and better balanced due to the use of 10-30% infill . Projects like Rammses predict 3D printed boat propellers weighing 40% less than conventional ones. By 2030, lighter titanium could replace steel in yacht production.

Efficient Repairs

3D printing can expedite and reduce the cost of repairs by producing spare parts on-site , a strategy already utilized in the automotive industry.

Lower Carbon Emissions

3D printed boats are more environmentally friendly due to research into lighter, more efficient materials like aluminum alloys for propellers , which can be printed anywhere to minimize transportation.

This innovation is crucial for the maritime sector striving to reduce carbon emissions and waste material through CNC machining. Searious Business, a Dutch association fighting against plastic pollution, even plans to print a 3D boat from plastic waste like Impacd Boats are.

Future of 3D Printed Boats

The boat design industry’s future includes a growing shift to 3D printing, resulting in cheaper, better-performing, and more eco-friendly vessels. The technology will revolutionize the industry by 2030, according to expert Gregory Marshall , with potential applications ranging from self-driving canal taxis to futuristic super yachts, as seen in the innovative 3Dirigo project.

Was this content helpful? Give us your feedback here.

Learn More About 3D Sourced

Exceptional Value with AnyCubic’s Latest 3D Printer Deals

11 Best 3D Printers in 2024 (All Budgets)

The 6 Main Types of FDM 3D Printer Explained

5 Best 3D Printers for Miniatures & Terrain in 2024

The 56+ Coolest Things To 3D Print in 2023

44 Common 3D Print Problems – Troubleshooting Issues 2023

13 Best Free 3D Modeling Software (For Beginners) 2024

6 Best Large 3D Printers in 2024 (All Budgets)

4 Fastest 3D Printers in 2024 (All Budgets)

5 Best 3D Printers For Beginners in 2024

40+ 3D Printing Industry Statistics (2024 Update)

22+ Coolest 3D Printed Robotics Projects (2024 Update)

8 Best DIY 3D Printer Kits in 2024 (From $150!)

3D Printing In Space – Top Projects in 2023

Best 3D Printed Shoes in 2023 (Sneakers, Heels & More)

The Best 3D Printer Buyer's Guide Resource & 3D Printer Reviews

[email protected]

3D Printers 3D Scanners 3D Software Guides Rankings Interviews News

Most Popular

Best 3D Printers Best 3D Scanners Best 3D Modeling Software Best 3D Slicers Best Resin 3D Printers Fastest 3D Printers Best Large 3D Printers

Useful Links

About us About the team How we do our reviews Careers Contact Us

Sign up to our newsletter

Privacy policy

Affiliate disclaimer

Editorial policy

- THE PRINCESS PASSPORT

- Email Newsletter

- Yacht Walkthroughs

- Destinations

- Electronics

- Best Marine Electronics & Technology

- Boating Safety

3D-Printing and Boatbuilding

- By Kim Kavin

- Updated: November 9, 2020

Last fall, when the University of Maine announced that it had created the world’s largest 3D-printed boat, imaginations ran wild. The idea of pressing a touchscreen and having a boat spit out of a gigantic printer suddenly felt possible. The notion of having a boat designed in a newfangled shape became a realistic-sounding option. And because the team in Maine had printed the 25-foot boat in just 72 hours, dreams of having production boats fly off factory lines became the stuff of serious conversations.

Practically speaking, here in reality, things are moving a bit slower on the innovation timeline. Habib Joseph Dagher, who leads the project as director of the university’s Advanced Structures and Composites Center, says the most likely immediate outcome will be a new way to make boat molds in the 50-foot range. “We think some of the first products that will come out over the next year will be full-size or close-to-full-size molds for boats made of recyclable materials,” Dagher says. “We think what’s going to happen next is shipyards evaluating the molds and giving us feedback, so we can get the technology honed in and able to roll out on a commercial scale.”

It’s a baby step in what experts say will be leaps and bounds of creative uses for 3D-printing technology once it can be harnessed to its full potential. Additive manufacturing, as it’s also known, is now the stuff of tests and experiments in fields as wide-ranging as aerospace and dentistry. Researchers are figuring out all kinds of materials that can be 3D-printed, as well as all kinds of ways to build the 3D printers themselves. The US Army is testing ways to use the machines in fields of combat, to print replacement parts on demand. Carnegie Mellon University just got funding to create software that will identify components in a CAD file that can be optimized and built better, such as in a different shape to reduce weight. BMW recently opened an entire additive-manufacturing campus in Germany, looking to improve upon the 300,000 or so parts the company built this way in 2019.

“One day, we’ll all be printing boats without a mold,” Dagher says, “but we’re all going to have to wait a little bit for that.”

As far as boats go, advances are happening all around the world. At the IYRS School of Technology and Trades in Rhode Island, the Digital Modeling and Fabrication Program is heading into its fourth year. Jeff Elsbecker, who heads it up, says that to understand where 3D-printing technology is today, we have to think about printers from the 1980s.

“If you remember dot-matrix printers, I would say that 3D-printing technology is almost where dot-matrix printers were,” Elsbecker says. “We’ll follow that with lasers and jet printing and all kinds of things. I suppose the far end would be replicators like in Star Trek.”

IYRS is focusing on teaching students design fundamentals and the basics of the technology. By the time they start working in naval-architecture firms or shipyards a few years from now, everything will have changed many times over, but the fundamental skills will still be needed to use whatever form the technology takes.

“There’s so many people doing so many things, one of the issues is also getting the machines to communicate with each other,” he says. “It’s sort of like deciding whether to go with beta or VHF. It’s at that stage.”

Boatbuilders who are early adopters in the 3D-printing world are using the technology for things like components and molds, says Bill Kenyon, director of education at IYRS. One example, he says, is Brooklin Boat Yard in Maine. It’s mostly a traditional boatbuilding and repair facility.

“When I was up there in January, they showed us a bow chock that the guys had designed,” Kenyon says. “They worked it all up in CAD and sent it off to a company that 3D-printed a prototype. They got it back, tweaked their design, sent it a couple of times, and then the guy could print it for them in titanium.”

Similar experimentation is happening in Auckland, New Zealand, where Richard Booten, head of design at Yachting Developments, says the yard’s purchase of 3D printers led to all kinds of ideas.

“Once you’ve got the machines, you start thinking about what you can use them for,” Booten says. “A lot of what we use them for is printing hull components—anything that has a highly complex shape. We’ve done exhaust-tube fittings. We’ve done hull fittings. We’ve achieved all sorts of stuff. Anything we would traditionally have gone and built on a CNC at great expense, we have done that. It’s really saving us some money by doing that.”

Yachting Developments is also now using the technology to plan vessel refits, to help clients understand how a final component will look and feel.

“The boat in the shed at the moment that we’re doing a refit to, they’re putting a new screen on the helm console,” Booten says. “Before we committed to making something out of carbon or fiberglass, we are able to print that addition and melt the screen in it so the captain can see what he’s actually going to get in real life. I think we’ve printed two or three of them now, and he’s changed stuff along the way. It’s relatively inexpensive to do that. Before, you’d kind of do it on the computer screen, and everybody would peer at it. The real-life version can look a bit different, so this is a real advantage.”

What will come next for the technology in boatbuilding, he says, is anybody’s guess. Right now, 3D-printing materials don’t compare to

fiberglass or carbon in terms of strength for building hulls, but new materials are being developed all the time. Most boatbuilders can’t afford a mammoth-scale 3D printer of their own, so they’re limited by whatever additive-manufacturing company can do the printing off-site. Boatbuilders, like everyone else, are just trying to keep up with the technology and think toward the future.

“There’s people around the world playing with all sorts of stuff with regard to 3D printing,” Booten says. “There’s people printing houses. There’s people printing bridges with welders stuck on the end of robots. It’s only going to gain more traction as a process and in the industry over the coming years.”

Old and New

It’s an odd thing, hearing the name Nathanael Herreshoff mentioned in the same sentence as 3D printing.

Herreshoff, of course, is the yacht designer best known for his America’s Cup designs of the late 1800s and early 1900s. He died in 1938, a time when the V-8 engine and the metal-cutting contour band saw were bleeding-edge technology.

The 3D printer wasn’t invented until decades later, in the 1980s. But that’s not stopping the team at the IYRS School of Technology and Trades in Newport, Rhode Island, from using the modern tech to build a Herreshoff.

This past year, the team was creating a replica of a 100-year-old Herreshoff design. Some of the hardware that Herreshoff had specified on the plans was not to standard; it had to be custom-made. IYRS decided to make it with 3D printing, converting the original drawings into files the printer could read.

“They worked them up in CAD and printed a 3D pattern, and the pieces could be made out of bronze,” Bill Kenyon, director of education, says of the team that Jeff Elsbecker leads at the school.

Superfici, a company based in the superyacht-building mecca of La Spezia, Italy, is using 3D printing in myriad ways, such as to create the sailboat rigging shown above. Paolo Licinio Nazzaro, at right in the photo below, is the company’s co-founder and managing director. His team worked with the owner of an Amer 94 to create what they say is the first 3D-printed helm console. It looked just like a traditional console, made from regular design plans.

Next, Superfici worked with Sacs to design and 3D-print the helm console shown on the opposite page. This console is a shape that can’t be created with a traditional mold, and the multifunction display is integrated in a way that lets it be upgraded later.

Today, the company is thinking about ways to make entirely new boat hulls, with features such as integrated lights and fenders.

- More: 3d Printing , September 2020 , Technology , Yachts

- More Yachts

New Flagship for Bering Yachts: The B165

Power catamaran popularity rising, “energy observer” zero-emission boat showcases sustainability, princess yachts’ y95: a flagship flybridge, for sale: sunseeker predator 68, for sale: cl yachts clb 72, 10 yachts under $500,000 you can have today, how to swing a compass on a boat.

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Reviews and How-To's

3D Printed Boats: Everything You Need to Know

A 3D printed boat is not only a possibility but it also exists in our world today. This might seem incredulous given that boats are much larger than most 3D printers, and 3D prints typically are not at all waterproof.

However, with additive manufacturing now a production method used everywhere, it seems the possibility is wide open. Be it spare parts for boats, design components for submarines, or even components of current turbines, 3D technologies are impacting boat construction and we’re here for it!

Scroll down for details on several examples of 3D printed boats, their processes, and the benefits of 3D printing boats- not necessarily in that order.

The 3D Printing Process

First things first, getting a basic understanding of the 3D printing process is a good way of easing into the idea of 3D printed boats. You should know that careful steps are taken to ensure that 3D printed boats are a success.

3D printing or additive manufacturing, which is the creation of real-world three-dimensional objects through a printing process, has its easy and difficult parts. That is not to say if you want to give it a try, you can’t handle it. You just have to follow the right steps.

To get started with the 3D printing process, the following are what you need to do:

- Design your Model

You can design your models by yourself using either professional software, which is quite expensive or free open-source software. This will allow you to create accurate and printable designs by typing instructions to combine different shapes to make complex objects.

Another option is making use of 3D scanners. However, these have their own disadvantages as they can only scan what they can see. Also, the models you create with the scanners might need tidying in software before printing; and the affordable scanners available might not have the precision required for functionally accurate items.

- Get a 3D Printer

Now that you can design your models, the next step in the 3D printing process is getting your own printer. This is a delicate decision and certain things must be taken into consideration if you want a 3D printer that delivers finished quality objects. First, consider the print volume of the printer as it lets you know what you can and cannot print.

Then check for nozzle size and remember, the smaller the better for accuracy. Thirdly, check the print heads of the 3D printer and note that if you want to print multiple colors, it’s better to get one with multiple heads. Finally, avoid printers that use proprietary cartridges and stick to the ones that use standard diameters of filament.

It’s advisable for you to join an online or local 3D printing community for more help on what kind of printer you should purchase. You’ll also be familiar with printers that are more popular within the community this way.

- Choose a Filament

Filaments are simply thermoplastics that melt instead of burn when heated and solidify when cooled. They can be shaped and molded, and are materials from which 3D objects are printed. The filament is generally supplied on reels and resembles insulated electrical wire.

The most common types of filament are PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene). While ABS has the advantage of being relatively resistant to heat and impact, it is made from fossil which is non-biodegradable. PLA, on the other hand, is obtained from renewable resources like corn and it can be a little brittle as well as not heat resistant.

This makes PLA easy to print but unsuitable for locations with temperatures regularly exceeding 50 ̊C. It is advisable for you to use the ABS filament if you are printing parts for your engine bay.

Benefits of 3D Printing Boats

A lot of great benefits come with 3D printing boats from production to customization. Rather than the ancient or traditional manufacturing ways of crafting boats, this additive manufacturing method offers an easier and more economical way of boat construction.

Here are the benefits in detail:

- No Excess Material

One thing about additive manufacturing is that only the amount of material needed to build your boat is used. Unlike the traditional subtractive manufacturing methods where materials are sure to be wasted, 3D printing your boat leaves no room for excess material. Even if there is, the excess material can always be used for a different printing job, making this method more sustainable and less expensive.

- Customization of Parts

There are different parts in a boat, each one improving it either in the area of speed or balance. With customization, you can create uniquely designed parts as well as parts that will help optimize the boat’s overall performance. You can simply adjust the 3D model to whatever pleases you. And with its low cost compared to the traditional manufacturing methods, customization with 3D printing is highly beneficial.

- Lighter Weight

A boat with less weight is mostly coveted because it’s faster and more balanced, causing a better performance. This is why 3D printing boats can be considered beneficial in this sense. Due to the fact that 3D printing materials are considerably lighter, and only the materials needed are used in 3D printing, the boats created are of lighter weight. This means that additive manufacturing produces parts that are lighter compared to parts made with a traditional manufacturing method.

- Spare Parts Replacement

It’s not unusual to see damages or bumps in the boat hull as the waters can sometimes get rough and nasty to ships and boats alike. There are even times when the boat hulls become so dirty that cleaning them properly can be almost impossible or simply too expensive.

In cases like this, replacing the boat hull totally is the best option since a damaged or dirty boat hull can lead to it losing its speed or effectiveness. Instead of spending so much money and time on getting a replacement, you can easily and quickly fix the parts with additive manufacturing.

Some Examples of 3D Printed Boats Today

In the past, the automotive industry has been known for incorporating 3D printing into their sector quite a lot. However, 3D printing is slowly but surely making its mark in the shipbuilding industry as well.

Several organizations have started making 3D printed boats for special purposes, and some of them are:

- Maine’s 3Dirigo Boat

Printed in just 72 hours, the Guinness world’s largest 3D printed boat and 3D printed solid item was announced by the University of Maine’s Advanced Structures and Composites Center in September 2019.

It was printed using the world’s largest thermoplastic 3D printer, measures 25’ (7.62m) long and weighs 5,000lbs (2,268kg). As part of a partnership with the U.S. Department of Energy’s Oak Ridge National Laboratory in Tennessee (ORNL), the aim of this project was to develop a large-format AM program based on 3D printing materials that contain wood fiber.

- MAMBO Fiberglass Boat

The MAMBO boat was the first functional 3D printed fiberglass boat to sail in Italian waters during the Genoa boat show. It was designed by Moi Composites in collaboration with Autodesk, Catmarine, Micad, and Owens Corning. The additive manufacturing method was used with continuous fiber composite materials.

The printing process also involved two robots that fabricated the boat’s components to be assembled. With this system, they were able to create lighter, yet strong and durable parts for the boat. There was also limited material waste and no need for molds. At 12’4” (6.5 meters) long, 8’2” (2.5 meters) wide, and 1763.7lbs (800kg) in weight, the MAMBO boat, unveiled in 2019, is truly outstanding.

All the tooling needed to build this boat was 3D printed by Yachting Developments, a New Zealand company that specializes in building boats with composite materials. The company went ahead to develop a branch dedicated to additive manufacturing as a way to accelerate the production of its ships. The AC9F went on to participate in the 36 th edition of the America’s Cup, and the teams were able to drastically reduce the manufacturing time of the final boat thanks to 3D printing.

- 3D Printed Kayak

This fully functional kayak was created by Jim Smith of Grass Roots Engineering. At 5 meters long, 0.5 meters wide, weighing about 30 kilograms, and using 28 different ABS plastics, this 3D printed kayak is the first of its kind. Using only screws, threaded inserts, and some silicone sealant alongside the ABS plastics, Jim made this a reality. He even created a custom, large-scale 3D printer to aid his outstanding innovation.

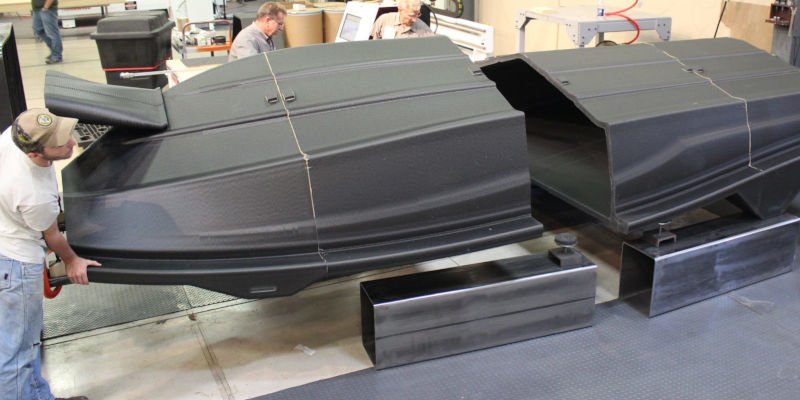

- 3D Printed Marine Hull

The master plug of this marine hull, alongside its print, assembly process, and trim process took less than ten working days to be completed with the use of an LSAM 3D printer. The Techmer Electrafil© ABS LT1 3DP material was used. After the printing process, the hull was coated with a finish and a fiberglass mold was implemented by tracing along with the pre-printed pattern. 3D printing of the marine hull optimized the feasibility, practicality, and economics behind it.

Going through the 3D printing process of building boats might seem difficult or tiring to you but with its many benefits and finished quality products, you know the process is well worth it!

To encourage you are even some of the best 3D printed boats in our world today that have been made a success by great minds. These real-life examples show you that 3D printed boats are a possibility and are being embraced more and more by the shipbuilding industry. Feel free to let us know your thoughts about 3D printed boats and contact us for more information!

Leave a comment

Comments must be approved before appearing

* Required fields

- Free 3D Models

- Sailboat free 3D models

- Sailboat (0)

- Boat (1616)

- Ship (1364)

- Watercraft (1285)

- Sail (1233)

- sail-boat (1088)

- Ocean (888)

- sail-ship (855)

- Vessel (590)

Free Sailboat 3D models

Free 3D Sailboat models available for download. Available in many file formats including MAX, OBJ, FBX, 3DS, STL, C4D, BLEND, MA, MB. Find professional Sailboat 3D Models for any 3D design projects like virtual reality (VR), augmented reality (AR), games, 3D visualization or animation. ...Show more

- Reset filters

Premium models

- Jump to page:

3D PRINT AN IOM YACHT

And go racing for less than half the price..

ALIOTH is an International One Metre class design optimized to be manufactured using 3D printing technology.

FOR HOME 3D PRINTERS

For FFF/FDM printers with 210 x 210 x 250 mm build volume or larger.

EASY ASSEMBLY

FAST MODERN DESIGN

The design team worked exhaustively in achieving modern, functional and harmonic shapes.

WHAT IS HAPPENING IN THE ALIOTH COMMUNITY?

Facebook group.

FREQUENTLY ASKED QUESTIONS & ANSWERS

Does alioth design cumply with the iom class rules.

Yes. A lthough the design has not been on the market for a long time, there are already some that have been registered with measurement certificate.

I am interested in home build an Alioth yacht but I don´t have a 3D printer.

If you don´t have a 3D printer but would like to build an Alioth, 3D printed kits are available for that purpose. More details soon.

I´ m thinking of purchasing a printer, which one would you recommend for a nice finish?

Most popular low price printers are good to print PLA material if they are well calibrated and work in a suitable place away from drafts or vibrations.

Make sure the build volume is 210x210x250 mm or larger.

Typically, you need to spend some time understanding and calibrating a 3D printer.

What material do you recommend to print the Alioth files?

PLA+ is stiff, has low shrinkage and is easy to print. The disadvantage is a low glass transition temperature.

Darker colours warp on direct sunlight as the temperature of the surface builds up fast. To avoid this, use bright clear colours.

Is the hull designed to be printed in vase mode?

Yes. Vase mode guarantees good layer adhesion and the best surface quality, and it reduces a lot the printing time.

What sailwinch servos can I use?

Files include three different servo trays for:

- Standard size (40×20 mm) sailwinch servos, like DSNA SW22HV.

- S100 sailwinch.

- RMG and ARS808 sailwinch servos.

- Privacy Overview

- Strictly Necessary Cookies

- Cookie Policy

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

More information about our Cookie Policy

3D Printed RC Sailboat

Introduction: 3D Printed RC Sailboat

Hi I'm Ethan and I spent large amount of time on what I would call a very interesting project.

Step 1: What Made Me Choose a Sailboat.

For about a year now I have been following the progress of the Tally Ho project. The YouTube channel Sampson Boat Co documents the mission to rebuild the 110 year old classic sailing yacht Tally Ho. Ever since I started watching this project I have been intrigued by the detail and design that goes into a sailboat. When I began this project I severely underestimated the difficulty of doing this project on Inventor and overestimated my AutoCAD Inventor skills. Although through the 11 hours I have spent trying to design and fix the endless errors created by those designs I can happily say that I'm proud of what I made and that I have progressed my inventor skills.

Step 2: Understanding the Design

I got the design for this boat from studying other ships rib sketches and designs. I used CAD Inventor to spline the shape of each rib to create the shape of the hull. The 3d model required a large ammount of work to get it to print correctly.

Step 3: 3D Printing

To print the boat I put the files into my slicer and scaled them up to 643% because of how its loaded in. The hull should add up to be about 20 inches or so. make sure to print with the largest flat surface of each part as the base to prevent warping. In you slicer's settings your going to set infill to 0 and the top and bottom layer to the minimum thickness so that you can cut the parts open. Although for the bow and stern only change the settings for the first layer. After that you should have all 6 parts done. You will also want to sand out the hole that the mast will insert into.

Step 4: Assembly

For assembling the parts I used 15 minute Resin. you should attach sets of 2 and think of where you want it to split. I chose to have the split be before the mast as shown by the black tape. The split is where I put in all of the electronics. When sealing up the split part of the boat I used hot glue so I could peel it away and reopen it to access the electronics. I know that's not the best way but I was trying to stay away from designing a hinge door on the deck.

Step 5: Electronics

For the electronics I tore apart an old RC car for the servo and receiver with matching remote. I went to a hobby shop and bought a AA battery pack for the power supply. The Servo was placed into a cut out I made in the deck with a Dremel and the rest was placed inside. Remember that depending on what your using for ballast and where it is in the boat you might have to take into account where the battery pack is placed.

Step 6: Ballast and Rudder

For the ballast I used stainless steel bb gun ammo because of how heavy it is and that is more or less form fitting. you can use other materials for ballast but take into to account how you will secure it in place. The rudder is made out of a cut as sanded paint mixer and the shaft is a shaped piece of solder with a rivet head hammered onto the top end to make sure the servo doesn't disconnect.

Step 7: Mast and Lines

Around the hull are two loops and two rods that are used as tie down points for the lines the attach to the top of the mast. Mast was also assembled using resign. Once you insert the fully assembled mast you should take string or wire and tie each of the four points to the top of the mast. Once the lines are done I cut out the mainsail using a Zip-Lock bag. the joints are made of tape and the beam along the bottom of the sail is another piece of solder.

Step 8: The Printable Files

Attachments.

Participated in the Make it Move Contest 2020

Recommendations

Remake It - Autodesk Design & Make - Student Contest

Fix It Contest

Engineering in the Kitchen - Autodesk Design & Make - Student Contest

Revolutionizing RC Sailboats with 3D Printing Technology

- By - Kyle Hilson

- Posted on May 3, 2023 June 2, 2023

- Posted in RC Boats

RC sailboats are a popular hobby enjoyed by many people worldwide. They are miniature models of real sailboats that are powered by wind and controlled remotely. RC sailboats come in different shapes and sizes, and enthusiasts can easily customize their boats by adding decorations or changing the design of their boats. In recent years, there has been an increase in the use of 3D printing technology in the design and construction of RC sailboats. 3D printing technology has revolutionized the way hobbyists can create their sailboats, making it easier and more affordable to create custom designs. In this article, we will discuss the benefits of 3D printed RC sailboats, the design and build process, performance advantages, examples and success stories, maintenance and repairs, and the future of 3D printed RC sailboats. If you are looking to get into RC sailboats or want to take your hobby to the next level, read on to learn how 3D printing technology can take your RC sailboat experience to new heights.

Benefits of 3D Printed RC Sailboat

The benefits of 3D printing in the construction of RC sailboats are evident. Here are some of the advantages of using this technology:

- 3D printing makes it easier and more affordable to create custom RC sailboats

- Greater precision and accuracy in design and construction

- Boats can be made faster and with greater customization than traditional methods

- More complex designs can be achieved with 3D printing .

- Parts can be easily replaced in case of damage

- Access to a wide range of materials to choose from for printing

Several websites offer plans and designs for 3D printed RC sailboats that hobbyists can use as a starting point. Others sell 3D printed parts that can be used to upgrade existing sailboats. One such website is Cults3D, which offers several RC sailboat models available for download. With 3D printing, the possibilities for creating unique, personalized RC sailboats are endless.

What are the benefits of 3D printing in construction?

If you’re interested in learning more about 3D printing in construction or trying it out, you can check out websites like 3Dnatives or companies like ICON.

Design and Build Process

Building a 3D printed RC sailboat involves the following steps:

Design Phase

- Choose the right type of RC sailboat design

- Create a 3D model of the boat using a 3D software like Fusion 360 or Tinkercad

- Optimize the design for 3D printing by checking the design for potential errors and ensuring that it is watertight

Construction Phase

- Select materials suitable for 3D printing the boat

- Use a 3D printer to print the parts of the boat

- Assemble the parts of the boat

- Add electronics, such as a motor and servo , as necessary

It is interesting to note that the use of Fused Deposition Modeling (FDM) printers is popular for 3D printing RC sailboats. This is because FDM printers can print objects that are water-resistant and durable.

Before starting the print process, it is essential to choose the right filament material . Common materials used for 3D printing RC sailboats include PLA , ABS , Nylon , PETG , and TPU . PLA is a popular choice because of its ease of use, low cost, and eco-friendliness. On the other hand, Nylon is a very durable material that can withstand challenging sailing conditions.

Example of Bill of Materials

What is the structure of a sailboat.

A sailboat is composed of several parts that work together to navigate through water. Below is a brief overview of the typical structure of a sailboat:

- Hull – the main body of the boat, which provides buoyancy and stability

- Deck – the uppermost surface of the boat, which provides a platform for crew members to move around on

- Mast – a vertical pole that holds the sails aloft

- Sails – large pieces of fabric that are attached to the mast and boom and catch the wind to propel the boat forward

- Boom – a horizontal pole that holds the bottom of the mainsail

- Rudder – a flat piece of metal or wood at the stern of the boat that is used to steer

- Keel – a weighted fin that is attached to the bottom of the boat and helps keep it stable while sailing

Understanding the structure of a sailboat is crucial for sailing safety. If you’re interested in learning more about this topic, websites such as sailmagazine.com and sailtraining.org offer useful information and resources. Additionally, products such as “The Annapolis Book of Seamanship” by John Rousmaniere provide a comprehensive guide to sailing and sailboat anatomy.

3D printed RC sailboats offer several advantages over traditional models. Some of these advantages include:

Lightweight Construction

- 3D printing allows for lightweight construction, which improves the boat’s speed and maneuverability

- Designers can optimize the weight distribution of the boat to achieve optimal performance

Design Flexibility

- 3D printing enables designers to create complex geometries and designs that are not possible with traditional methods

- Designers can create more aerodynamic and hydrodynamic shapes, leading to faster sailing speeds

Customizability

- With 3D printing , designers have complete control over the design and construction of the boat

- Customization options are virtually endless, from hull shape to color scheme

Interestingly, a 3D printed RC sailboat designed by Gary Smith set the record for the fastest wind-powered boat in 2016, reaching a speed of 68.01 miles per hour. This demonstrates the potential that 3D printed RC sailboats have for high performance.

Several websites offer resources for anyone interested in building their own 3D-printed RC sailboat , including Thingiverse , Pinshape , and MyMiniFactory . These sites offer boat designs, 3D printing instructions, and other resources to help enthusiasts get started on their projects.

Can you 3D print a sailboat?

Yes, it is possible to 3D print a sailboat, however, it largely depends on the design and size of the sailboat.

- 3D printing can be cost-effective and offer limitless possibilities for custom designs.

- Large 3D printers are required for printing bigger scale boats.

- 3D printing technology is still evolving, and its application in the marine industry is still limited.

Various companies like the Italian start-up Livrea Yachts have used 3D printing technology to create customized sailboats. However, it’s worth noting that traditional sailboat manufacturing methods are still the most commonly used.

There are numerous 3D printed RC sailboats that have gained popularity in recent years, including:

OpenRC Sailboat

- Designed by Daniel Noree and featured on Thingiverse, the OpenRC Sailboat is a popular option for hobbyists

- It features a sleek design, with a V-shaped hull and three triangular sails

- The boat is customizable, with options for different material thicknesses depending on desired weight and durability

Ada Lovelace’s RC Sailboat

- Engineering students at the University of Southampton recreated Ada Lovelace’s 1845 sailboat design using 3D printing and modern RC technology

- The resulting boat was not only functional, but also historically significant

Little RC Yacht

- Designed by MyRCCar, this boat features a classic yacht design with modern RC components

- The boat is easy to assemble and can be printed in sections to fit smaller 3D printers

In addition to these designs, many hobbyists have successfully designed and built their own 3D printed RC sailboats . Online communities such as RC Groups and the 3D Printing subreddit offer resources and support for those interested in pursuing this hobby.

What is the most popular RC sailboat class?

The most popular RC sailboat class is the International One Metre (IOM) because of its affordability, ease of transportation, and competitive racing opportunities worldwide. Some of the benefits of IOM racing include:

- A well-established class with a large and active community

- An affordable price point for both building and purchasing ready-to-sail boats

- Ease of transportation due to the smaller size of the boats compared to other classes

- Opportunities to race competitively at local, national, and international levels

For more information about IOM racing, visit the International Radio Sailing Association website.

Maintenance and Repairs

Maintaining and repairing a 3D printed RC sailboat is similar to traditional RC sailboats, with a few key differences due to the materials used. Here are some tips to keep your 3D printed RC sailboat in top condition:

- Use a low-strength filament for parts that require flexibility, such as sails or rigging

- Inspect the boat regularly for cracks or damage, as 3D printed parts are more prone to breakage than traditional materials

- Keep the boat dry and store it in a protective case to prevent warping

- Use sandpaper or a file to smooth any rough edges or corners on printed parts

- Replace parts as necessary, such as the sail or rigging, with 3D printed replacements

There are online resources available for 3D printed RC sailboat enthusiasts to purchase replacement parts or upgrades to their boat. Many hobbyists offer 3D printed parts for sale on websites such as Etsy and Ebay. Some sites also offer free designs for 3D printed RC sailboat parts, such as Thingiverse and MyMiniFactory .

Conclusion and Future of 3D Printed RC Sailboats

In conclusion, 3D printing has opened up new possibilities for the world of RC sailboats, allowing for greater customization and precision in design and construction. While the technology is still relatively new, the potential for growth and innovation is endless. As the demand for 3D printed RC sailboats increases, we can expect to see further advancements in materials, printing methods, and design.

Those interested in exploring this hobby can access a wide range of resources, including software and online communities, to help get started. With the introduction of affordable 3D printers and user-friendly design software, creating a custom RC sailboat has never been easier.

Overall, 3D printed RC sailboats are an exciting new development in the world of RC sailboats. The possibilities for customization, innovation and personalization are limitless. We look forward to seeing what the future holds for this growing hobby.

Previous Article

Next article.

PRINT AT HOME AN IOM SAILING YACHT

And sail for less than half the price..

ALIOTH is an International One Metre class design optimized to be manufactured using 3D printing technology.

FOR HOME 3D PRINTERS

For FFF/FDM printers with a minimum print volume of 210 x 210 x 250 mm, and 0.4 nozzle.

EASY ASSEMBLY

FAST MODERN DESIGN

The design team worked exhaustively in achieving modern, functional and harmonic shapes.

WHAT WILL YOU RECEIVE?

Ficheros STL del casco, de los refuerzos internos y de las plataformas de los equipos RC.

G-CODE files for PLA/PLA+ material, generated with a extensively tested slicer setting.

General 3D printing and assembly instructions .

You will also have access to the Alioth community on Facebook.

Special price, 3d printing technology is constantly becoming more useful and we are offering this special price as a one-time launching offer., take advantage of this amazing deal before it is too late, alioth gcode files + user licence.

115.00 €

WHAT IS HAPPENING IN THE ALIOTH COMMUNITY?

We use this group to help alioth users during the printing and assembling processes..

FREQUENTLY ASKED QUESTIONS & ANSWERS

Is the hull designed to be printed in vase mode.

Yes. Vase mode guarantees good layer adhesion and the best surface quality, and it reduces a lot the printing time.

What material do you recommend to print the Alioth files?

We recommend PLA+ or PLA.

PLA is stiff, has low shrinkage and is easy to print. The disadvantage is a low glass transition temperature.

Darker colours warp on direct sunlight as the temperature of the surface builds up fast. To avoid this, use bright clear colours.

Don’t leave printed parts in a car on hot summer days, as the temperature can easily rise above 50°C.

What sailwinch servos can I use?

Files include three different servo trays for:

- Standard size (40×20 mm) sailwinch servos, like Turnigy 6114.

- S100 sailwinch.

- RMG and ARS808 sailwinch servos.

What other parts do I need to complete my Alioth boat?

Hull fittings kit (available in our online store).

Rudder and keel (SailingLAB carbon rudder and keel are available in our online store).

Radio controlled equipment.

Rigs (mast, booms, sails, etc).

How do I obtain my purchased files?

Privacy overview.

World’s Largest 3D Printed Boat Unveiled by Al Seer Marine

Share this Article

When astonishing case studies emerge in the additive manufacturing (AM) sector, it’s become a habit of mine to approach them with caution. After all, there are so many dubious stories and applications that more evidence is needed before they can be taken at face value. For that reason, I was hesitant about 3D printed autonomous boats. However, Al Seer Marine , which commissioned “ the world’s largest” robotic arm 3D printer from CEAD, may very well be on track to deliver on the concept after winning the Guinness World Records title for the Largest 3D Printed Boat.

Dubbing it the “world’s first” 3D printed water taxi, Al Seer Marine and Abu Dhabi Maritime, part of AD Ports Group (ADX:ADPORTS) unveiled the craft 3D printed from recycled PIPG (30% glass fiber and UV stabilizer). Measuring 11.98 meters in length and 3.594 meters in width, the 3D printed taxi is able to fit 29 passengers, including crew, with additional space for bicycles and wheelchairs. The boat is expected to hit Abu Dhabi’s water taxi network in late 2024. The previous title of “World’s Largest 3D Printed Boat” went to the University of Maine , which used an Ingersoll system to fabricate the craft.

“This record-breaking accomplishment is a testament to our unwavering dedication to sustainable practices and pioneering engineering,” proudly stated Guy Neivens, CEO of Al Seer Marine. “Beyond achieving a The Guinness World Record, this endeavor serves as a clarion call to the industry, urging the adoption of greener technologies. We take immense pride in crafting this extraordinary water taxi within our very own facility, a beacon of our commitment to a sustainable future.” Capt Saif Al Mheiri, Managing Director at Abu Dhabi Maritime, contributed, “Our partnership has given birth to something truly extraordinary. This 3D printed water taxi represents a significant leap forward in sustainable maritime transportation and a unique experience for our customers.”

The World’s Largest 3D Printed Boat. Image courtesy of Al Seer Marine.

Al Seer Marine, located in Abu Dhabi, specializes in a range of maritime services including boat construction, yacht management, refits, and the production of unmanned sea drones. This public enterprise boasts a workforce exceeding 1200 individuals. It operates under the umbrella of the International Holding Company, a notable entity that, as detailed in a Financial Times report , rapidly rose from relative anonymity to achieve a valuation of $240 billion.

The International Holding Company is presided over by Sheikh Tahnoon bin Zayed al-Nahyan. In addition to his role at the helm of this company, Sheikh Tahnoon holds significant positions within Abu Dhabi’s ruling family as a full brother of the ruler and also serves as the national security chief of the country.

Managed by Abu Dhabi Maritime, Abu Dhabi’s water taxi network was launched in November 2022 as a means of traversing the city’s waters and access its prime locations. It connects popular tourist destinations and provides ferry services linking islands to the mainland. Its parent company, AD Ports, is the exclusive developer and regulator of ports and related infrastructure in Abu Dhabi.

Al Seer’s previous efforts in 3D printing unmanned surface vessels (USVs) included HYDRA drone boat revealed in February of this year. Weighing 345 kg and five meters long, HYDRA was meant initially for intelligence, surveillance, and reconnaissance missions. Drone boats have garnered attention for potential intelligence gathering, particularly in areas like the Persian Gulf where maritime surveillance is seen as increasingly vital.

Because the government and wealth of the United Arab Emirates is so closely linked, it’s possible for the country and the individual emirates to quickly implement large-scale strategies. In the case of Dubai, this has seen significant attention placed on additive construction, while Abu Dhabi is executing this novel transportation network. Thanks to 3D printing, it will be able to deploy 3D printed boats at a rapid pace such that it shouldn’t be entirely surprising if Al Seer doesn’t achieve its lofty goals.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

- Enter your email address *

- Email This field is for validation purposes and should be left unchanged.

Recent News

3D Printing Webinar and Event Roundup: March 24, 2024

3D Printing News Briefs, March 23, 2024: AM in the US Coast Guard, Navy, & More

3D Printed Art

3D Printed Food

3D Printed Guns

You May Also Like

Nexa3d welcomes 3d-fuel materials to its expanding family.

California-based Nexa3D is quickly expanding its product offerings, acquiring assets that both grow its overall additive manufacturing (AM) processes and materials. Complementing its November 2023 purchase of material extrusion firm...

3D Printing News Briefs, March 16, 2024: Partnerships, Affordable Bioprinter, & More

We’re starting with dental 3D printing news today, and then moving on to some new partnerships. Then it’s on to some interesting university research about 3D printing plant-based pharmaceuticals, but...

3D Printed Micro Antenna is 15% Smaller and 6X Lighter

Horizon Microtechnologies has achieved success in creating a high-frequency D-Band horn antenna through micro 3D printing. However, this achievement did not rely solely on 3D printing; it involved a combination...

3D Printing News Briefs, March 9, 2024: ADDiTEC Racing, 3D Printed Functional Brain Tissue, & More

In 3D Printing News Briefs, we’re starting with automotive applications, as ADDiTEC launched its new racing division. Moving on, 3D-Fuel is now part of the Nexa3D family, and researchers have...

Print Services

Upload your 3D Models and get them printed quickly and efficiently.

- 3DPrinting Business Directory

Site Sponsor

Additive Manufacturing Strategies

Networking & Intelligence Summit, February 4-6, 2025

3D Printing jobs around the world.

- I would like to also register for free and access proprietary industry data from SmarTech and 3DPrint.com

- Name This field is for validation purposes and should be left unchanged.

3D Printing Guides

- Desktop 3D Printer Buyer’s Guide

- 3D Scanner Buyer's Guide

- Metal 3D Printer Guide

- Industrial Polymer 3D Printer Guide

- The 3D Systems Zone

- The HP Zone

- Velo3D Zone

- Desktop Metal Zone

- Bioprinting Zone

- FlashForge Zone

- The Space Zone

- 3D Printing Stocks Zone

Register to view and download proprietary industry data from SmarTech and 3DPrint.com Questions? Contact [email protected]

Already have an account?

- First name *

- Last name *

- Password * Enter Password Confirm Password

- I agree to receive the 3DPrint.com Daily newsletter and promotional email correspondence.

- České fórum

- Polskie forum

- Forum Français

- Forum Italiano

- Foro Español

- Deutsches Forum

- Recent Posts

- Announcements

3D printer on a sailboat

3D printer on a sailboat

I live full-time on a sailboat, a 47ft catamaran and I would like to acquire a 3D printer to ba able to manufacture some small parts aboard like plastic gears, covers and other small bits and pieces made out of ABS, ASA or even composite. Uninterrupted power supply is not an issue.

I wonder if the ever so slight movement of the boat would affect the printing? If you think it's doable, what model would you recommend and what extra precautions would I need to take please?

Best Answer by 3Dprinting_on_SVRondo :

(I don’t know how to work this website)

I live on a leopard 46 catamaran(SV Rondo). I am 16 and I have been making boat parts for my boat. My printer is a modified ender 3 and I have been printing with it for 2 years. I should have gotten the prusa mini though. My friend has one on his boat and it is perfect for 3d printing on a sail boat.

I print with nylon, polycarbonate, nylonx, ASA (second favourite), PETG, TPU, polycarbonate carbonfiber (favourite), and PLA.

the most common printing material is ASA for us resistance and Polycarbonate carbonfiber for both sun resistance and super strength. That’s all you would really need. I dont recommend PLA for boat parts because of its poor sun resistance.

As for moisture, I have a dry box I made and use while printing. All the filament rolls are in freezer bags but I recommend vacuum bags. Nylon is tough to keep dry. Make sure it stays away from open air even while printing. If you take the right precautions, you don’t need a dryer on your boat. If your oven gets down to 80c you can use that to dry filament.

As for enclosures, I recommend one. I have my printer in a closet which is good enough for me. I also had a diy one out of styrofoam sheet which worked well.

As for power it doesn’t use too much, I don’t know exactly how much off the top of my head. Having an enclosure helps. You can hook your printer up directly depending on the printer voltage and your boat voltage. Most printers either use 12v or 24v. They have an adapter to convert 120 or 230 to 12 or 24v. You could possibly chuck the power supply out if your printer and your boat are the same voltage. For power outages, my printer has a recovery program and can resume after power outages. I think prusa has that feature as well.

As for design I use fission 360 for free and it is great. Most parts you won’t find online so you better learn to do cad(it’s pretty easy) It has offline mode but you need to download another app to use the 3d print tool in it. I think it is called mesh mixer. I use callipers to measure parts.

As for cost and parts, I order my filament from amazon ($50 usd : 1kg pc-cf, $15 usd : 1kg ASA, $30 : 1kg polycarbonate) you can get good filament from amazon for very cheap. I recommend for bed surface (g10 for nylon, ASA, and nylonx, polycarbonate sheet for polycarbonate filament and ASA, PEI for pc-cf and basic filament. I recommend basic spares like nozzles and hot end parts. I also recommend getting hardened steel nozzle for carbon fibre filaments.

3d printing on boats is very useful sometimes. If you have one, I bet some other people will want you to make them stuff. It is certainly possible to print on a boat. I hope this poorly written comment is helpful for anyone wanting to get a printer on a boat. I highly recommend getting a prusa printer on your boat.

Bon Printing

If it was me, I would get an MK3S+ and living on the water you will for sure want to invest in a filament dryer, not one of the weak ones e.g the Esun or sunlu single roll dryers or any like that. your going to want to look into something like a Printdry Pro, or DIY build one out of a powered food dehydrator. the MK3 printer will come with a filament spool hanger, however you will not want to use it on the boat as the motion would tend to make the 1 kg. 2.2 lb. spool shift its weight, and depending on the day this could cause problems. but you will want to keep your filament in the dehydrator running while printing anyway, so this shouldn't matter and of course you will want dry low humidity storage for any filament not in use. I personally use a foodsaver vacuum sealer to reseal my filaments when not in use, many use what is called a dry box. and of course secure your appliances (printer & filament dehydrator)

that's all I can think of at the moment.

Bon voyage,,. ur ahh Printing

Swiss_Cheese

The Filament Whisperer

Not sure if it would help or hinder but I'd try put it into a gimbal.

I assume you will only use the printer in a sheltered mooring.

I guess it helps being a cat cause you don't have to worry so much about roll.

In a boat, you will have to take care of the ventilation.I would not print ABS in a cabin.

Uninterrupted power supply is not an issue.

Stepper motor circuits can be electrically noisy so be careful not to put it on the same circuit as your nav and vhf electronics, do not run cables in the same conduits as your depth sounder, do not use your NMEA conduits. Keep it well clear of your compasses.

Engine rooms (probably not an issue in your case) and galleys are not suitable environments due to airborne grease.

Some means of protection from stray breezes would help prevent warping, it need not be a full enclosure.

@swiss_cheese's comments on drying are spot-on.

No problems in port - as long as you're not being banged against the wall by passing wash. Shock causes more problems than ordinary wave motion.

It has been done. I have emailed .stl's to a yacht for print-on-board spares...

You need a printer with a full frame, a Prusa Mini will not be happy as the stresses on the unsupported end of the X axis vary but a Mk3 should be OK as would a core XY.

Spools will need a horizontal mount to avoid varying stresses with a vertical or hanging mount.

Be aware that many printable plastics are vulnerable to UV light, keep your stock filaments in the dark and protect the parts you print ... after all, it's paint that keeps boats afloat.

Avoid printing from PLA, which would not only melt under the sun but also crumble over time, due to the UV radiation, choose ASA or other technical materials and you should be golden. The mentioned dry box is a good idea. The movement of the boat shouldn't be an issue really, especially with Mk3. The printer can print even upside down (I've seen it on my own eyes :))

Printing upside down isn't that hard

You can align the printer in any direction you want as long as the z-offset is calibrated properly. You will definitely see some marks from the vibrations of the waves if you are not using a gimble or something else, assuming that you are sailing on the ocean and not on a 2 hectare lake with no waves at all 😀

Those marks shouldn't cause much trouble, just an imperfection on the print surface.

Many people use damping mats in combination with a very solid surface to keep the vibrations to a minimum and generate the best foundation for a 3d-printer.

I wouldn't recommend a Prusa Printer anyways when it comes to printing large ABS / ASA parts. You will definitely need a closed environment with a heated chamber.

I'm printing ABS+ from eSun on my Prusa Mini quite satisfactory, but I'm using a heated chamber and as well printing only smaller parts.

Electrical EngineerWorking on master’s degree in electrical engineering

Printing on a boat is great.

Reply to my own post

Catamarans don’t move a whole lot at anchor. prusa mini is fine, my friend has one on his catamaran but i don’t know if he as tried on passage. i print on a modified ender 3 on passage. it isn’t bolted down or anything. even on rough passages it prin....

Catamarans don’t move a whole lot at anchor. Prusa mini is fine, my friend has one on his catamaran and it prints flawlessly but I don’t know if he as tried printing on passage. I print on a modified ender 3 on passage. It isn’t bolted down or anything. Even on rough passages it prints like a charm

Ventilation

I have a hatch I open when printing ASA because of the fumes. I usually have the hatch closed if I’m printing something else.

It depends on your local waters and your mooring. If you are on your home mooring most of the time then you will quickly learn what to expect but if mostly on passage it's important to be prepared for worse conditions.

Thanks very much for your feedback on your setup and all the details. I mean everybody above had very positive comments about using a 3D printer on a boat (thanks all!) but you've done it for a few years and even print on rough passages, I'm amazed!

Where abouts are you cruising at the moment? We are in the Caribbean on SV Kapa Rico. do you have Whatsapp? Can you please contact me ? my number is +590690133153

Roll of ocean

Fascinating topic. I can see where this would be useful on the float. Does the roll of the ocean effect the printer?

-------------------- Chuck H 3D Printer Review Blog

This is a great idea!

Printing on board!

Fairly new to 3D printing but 35 years on board! We have a MK3S+ on board a 46 foot ketch. Have not tried printing on passage but no problem with wakes where we are. We are getting set to start printing prosthetic hands and lower arms (e NABLE) here. Using a filament dryer as here in Guatemala it is a touch humid. Honestly unless conditions are really kicking I don't see any issues with it.

filament dryer onboard

Hi Eric, thanks for the reply. Glad to hear it's all working well onboard, especially on a monohull at anchor which I thought might be more challenging. I never heard of e Nable, looked it up and it looks a fantastic idea, will definitely get into that once we get out 3D printer. I take it you are happy with your MK3S+? Any spare parts recommendations to be carried onboard? Nozzles, thermistors, what else? Also what filament drier did you go for? food dehydrators are quite power hungry, somebody above didn't recommend the Sun nor the Sunlu, maybe the EIBOS Filament Dryer Box might be a better option?

RE: print dry

EIBOS Filament Dryer Box is a good product. I have one. I prefer the food dehydrator and Print Dry, but EIBOS works.

EIBOS Filament Dryer box

Thanks Chuck, do you believe this dryer doesn't work as well as a food dehydrator or you just prefer to use the latter?

I think it works fine. I can get a dehydrator for 1/4 the price and it works just as well.

Posted by: @harvey Thanks Chuck, do you believe this dryer doesn't work as well as a food dehydrator or you just prefer to use the latter?

Latest Post: Je vend ma MK3S de 2020 Our newest member: Ken Colborne Recent Posts Unread Posts Tags

Forum Icons: Forum contains no unread posts Forum contains unread posts

Topic Icons: Not Replied Replied Active Hot Sticky Unapproved Solved Private Closed

Our expert deal-hunting staff showcases the best price drops and discounts from reputable sellers daily. If you make a purchase using our links, CNET may earn a commission.

Save $100 on a Super Fast 3D Printer During Amazon's Big Spring Sale

The Adventurer 5M is a good beginner printer, and this discount makes it a must-buy.

- 6 years working professionally in the 3D printing space / 4 years testing consumer electronics for large websites.

In this new age of 3D printing, fast 3D printers are starting to arrive thick and fast. The Adventurer 5M from Flashforge is one such printer, and while it is a stripped-down, simple affair, it is still extremely fast yet maintains a good quality product as the end result. Today, at Amazon's Big Spring Sale the Adventurer 5M has a $100 discount, bringing the price to an almost impulse level of $300. All you have to do is clip the coupon on the page to secure the deal.

The Adventurer 5M is a CoreXY printer that uses the Klipper OS. It has advanced features like auto bed leveling, filament run-out control and automatic z-height adjustment. All of those combine to generate some really nice-looking prints. The machine itself is bare-bones, it doesn't have side panels, a front door or a top, so if you are looking for something with an enclosure, you can opt for the Adventurer 5M Pro , which is also $100 off with an on-page coupon, making it $399, the standard price of the 5M. I've been reviewing these printers over the last month, and they'll be added to CNET's best budget 3D printer list with its next update.

If the Adventurer 5M doesn't quite fit your needs for a beginner 3D printer, check out our other 3D printer deals . You're sure to find something great.

More shopping deals from CNET

CNET is always covering a wide array of deals on tech products and much more. Start with the hottest sales and discounts on the CNET Deals page , and check out our CNET Coupons page for current Walmart discount codes , eBay coupons , Samsung promo codes and more from hundreds of other online stores . Sign up for the CNET Deals Text to get daily deals sent straight to your phone. Add the free CNET Shopping extension to your browser for real-time price comparisons and cash-back offers. Peruse our gift guide , which includes a full range of ideas for birthdays, anniversaries and more.

Computing Guides

- Best Laptop

- Best Chromebook

- Best Budget Laptop

- Best Cheap Gaming Laptop

- Best 2-in-1 Laptop

- Best Windows Laptop

- Best Macbook

- Best Gaming Laptop

- Best Macbook Deals

- Best Desktop PC

- Best Gaming PC

- Best Monitor Under 200

- Best Desktop Deals

- Best Monitors

- M2 Mac Mini Review

- Best PC Speakers

- Best Printer

- Best External Hard Drive SSD

- Best USB C Hub Docking Station

- Best Keyboard

- Best Webcams

- Best Laptop Backpack

- Best Camera to Buy

- Best Vlogging Camera

- Best Tripod

- Best Waterproof Camera

- Best Action Camera

- Best Camera Bag and Backpack

- Best E-Ink Tablets

- Best iPad Deals

- Best E-Reader

- Best Tablet

- Best Android Tablet

- Best 3D Printer

- Best Budget 3D Printer

- Best 3D Printing Filament

- Best 3D Printer Deals

- Dell Coupon Codes

- Newegg Promo Codes

- HP Coupon Codes

- Microsoft Coupons

- Anker Coupons

- Logitech Promo Codes

- Western Digital Coupons

- Monoprice Promo Codes

- A4C Coupons

IMAGES

VIDEO

COMMENTS

3D Model STL File for CNC Router Laser & 3D Printer Sailboat With Cannons. US$3.25 Closure-hublot-GOIOT. US$14.13 OLD SPICE SAILBOAT. Free Rotula Para Prolongador De Caña Timón optimist diametro 13 Mm - Optimist Rudder Rod Extension Ball Joint Diameter 13 mm. US$5.86 small sailing boat ...

78.1 %free Downloads. 1314 "sailboat" 3D Models. Every Day new 3D Models from all over the World. Click to find the best Results for sailboat Models for your 3D Printer.

Discover free 3D models for 3D printing related to Sailboat. Download your favorite STL files and make them with your 3D printer. Have a good time!

Each Cults 3D designer has his own vision of the boat, so you will find incredibly realistic boats designed like models, but also more childish boats to play in the bath. Obviously impossible to talk about 3D printing and boat without mentioning the famous Benchy, this boat that floats and is an excellent calibration test for your 3D printer.

Pegasus 88m - The Carbon-Neutral Superyacht. The Pegasus 88m is a 3D printed 'superyacht' that even in 2023 only really exists on paper, but is still well worth talking about. Designed as a completely carbon neutral 3D printed luxury boat, it was conceived with nature a the forefront of designer Jozef Forakis' mind.

MAMBO, a Functional 3D Printed Fiberglass Boat. Unveiled in 2019 during Formnext, the MAMBO boat was designed by Moi Composites, in collaboration with Autodesk, Catmarine, Micad and Owens Corning. It is 12'4″ (6.5 meters) long, 8'2″ (2.5 meters) wide and weighs about 1763.7 lbs (800 kg). The peculiarity of the project is that it turned ...

Things tagged with ' boat '. 0 Thing s found. Download files and build them with your 3D printer, laser cutter, or CNC.

A decorative sailing boat model which can be printed without supports. Prints in two halves and slots together ** I have also designed a stand for the model w. Explore. Categories. 3D Printers. ... 3D Printers. Articulated. Art. Costumes & Cosplay. Education. Fashion. Functional. Gridfinity. Miniatures. Multiboard. Health & Fitness. Hobbies ...

In fall 2019, the University of Maine created the world's largest 3D-printed boat, a 25-footer. University of Maine. "One day, we'll all be printing boats without a mold," Dagher says, "but we're all going to have to wait a little bit for that.". As far as boats go, advances are happening all around the world.

Revolutionizing sailboats: The power of 3D printing in the world of model footy sailboats. The 3D printed footy sailboat's design focuses on creating a lightweight and aerodynamic vessel that can perform well in a wind-powered race.; As a result of their lightweight frames, 3D printed footy sailboats can race at impressive speeds and are highly maneuverable on the water.

3D printing also greatly reduced the time it took to fabricate the boat, as well as making it a more economical project. Not only is the hull 3D printed, but the deck and other functional parts ...

A 3D printed boat is not only a possibility but it also exists in our world today. This might seem incredulous given that boats are much larger than most 3D printers, and 3D prints typically are not at all waterproof. However, with additive manufacturing now a production method used everywhere, it seems the possibility is wide open. Be it spare parts for boats, design components for submarines ...

Download 43 Sailboat free 3D models, available in MAX, OBJ, FBX, 3DS, C4D file formats, ready for VR / AR, animation, games and other 3D projects.

Most popular low price printers are good to print PLA material if they are well calibrated and work in a suitable place away from drafts or vibrations. Make sure the build volume is 210x210x250 mm or larger. Typically, you need to spend some time understanding and calibrating a 3D printer.

Step 3: 3D Printing. To print the boat I put the files into my slicer and scaled them up to 643% because of how its loaded in. The hull should add up to be about 20 inches or so. make sure to print with the largest flat surface of each part as the base to prevent warping. In you slicer's settings your going to set infill to 0 and the top and ...

77.7 %. free Downloads. 1467 "rc sailboat" 3D Models. Every Day new 3D Models from all over the World. Click to find the best Results for rc sailboat Models for your 3D Printer.

Select materials suitable for 3D printing the boat. Use a 3D printer to print the parts of the boat. Assemble the parts of the boat. Add electronics, such as a motor and servo, as necessary. It is interesting to note that the use of Fused Deposition Modeling (FDM) printers is popular for 3D printing RC sailboats.

The University of Maine broke three world records when it unveiled a boat produced by its polymer 3D printer. The 3D printer can produce objects as long as 1...

BOAT IDENTIFICATION; LOGIN; Select Page. PRINT AT HOME AN IOM SAILING YACHT and sail for less than half the price. ALIOTH is an International One Metre class design optimized to be manufactured using 3D printing technology. FOR HOME 3D PRINTERS. For FFF/FDM printers with a minimum print volume of 210 x 210 x 250 mm, and 0.4 nozzle.

Al Seer's previous efforts in 3D printing unmanned surface vessels (USVs) included HYDRA drone boat revealed in February of this year. Weighing 345 kg and five meters long, HYDRA was meant ...

Rc sailboat MICROMINI 065. US$87.19. NEW 2024!!!! IOM CLASS BOOM SHEET TRACK SLIDE 11MM / RING DE BÔME 11MM POUR RÉGLAGE D'ECOUTE. US$3.27. IOM CLASS, NEW 2024!!! BAND WITH EYE FOR BOOM 11MM, BAGUE D'ECOUTE POUR BÔME 11MM. US$1.63.

3D printer on a sailboat. Hi, I live full-time on a sailboat, a 47ft catamaran and I would like to acquire a 3D printer to ba able to manufacture some small parts aboard like plastic gears, covers and other small bits and pieces made out of ABS, ASA or even composite. Uninterrupted power supply is not an issue.