Yachting Monthly

- Digital edition

Yacht rigging: your essential pre-season rig check guide

- Duncan Kent

- February 7, 2023

Few things are more important during the spring fit-out than a thorough yacht rigging and spar inspection. Duncan Kent runs through the priorities

During the spring fit-out we often appear to lavish far more attention on the engine and electrical systems than we do on the rig, despite the latter presenting a much greater risk to both yacht and crew should it fail in any way. However, because a yacht’s standing rigging has so many possible weak points it can be tricky to predict when any part of it is about to break. Close inspection should be a mandatory element of the pre-season preparations and checks.

A detailed rig check will rarely take more than a couple of hours to complete and should really be carried out prior to any long passage or extended cruise.

There are a number of telltale signs that should be looked for before, or soon after you launch for the new season, and several maintenance tasks that can be carried out to prolong the life of the rigging.

When inspecting your rig, it makes good sense to make an inventory of all the parts and their dimensions, as well as taking photographs of them.

It’s always advisable to un-step the mast every few years to check it over thoroughly at ground level. It makes close inspection of areas like the spreader roots, mast terminals and halyard sheaves much easier. If you are in any doubt about the condition of any part of the rig, it’s worth getting your local rigger to come and have a look.

This level of inspection may also keep your insurance company happy to continue covering an ageing rig, so it is worth doing every few years.

The mast step is a cast fitting under heavy loads and needs a thorough check

I always start the pre-season rig checks by inspecting the spars, commencing with the mast step and foot. The high compression forces on the mast step can put severe strain on both the T-bar (the plate on the deck) and step (the cast fitting that takes the loads in the bottom of the mast tube), particularly if there is any imbalance in the rig tension.

This is also an area where the salt water can gather in a pool, making it very prone to corrosion. Look closely at any rivets around the base and at the mast section itself for signs of corrosion or cracks. Get them looked at by a professional if there are working signs, to evaluate what repairs may be necessary.

With keel-stepped masts it’s especially important to check for corrosion at the foot as often they sit in the damp bilge and, being out of sight, are often overlooked. The same with the deck seal which, if leaking, will cause water to dribble slowly down the mast, creating a puddle at the foot. Replace any seals that are looking worn or perished.

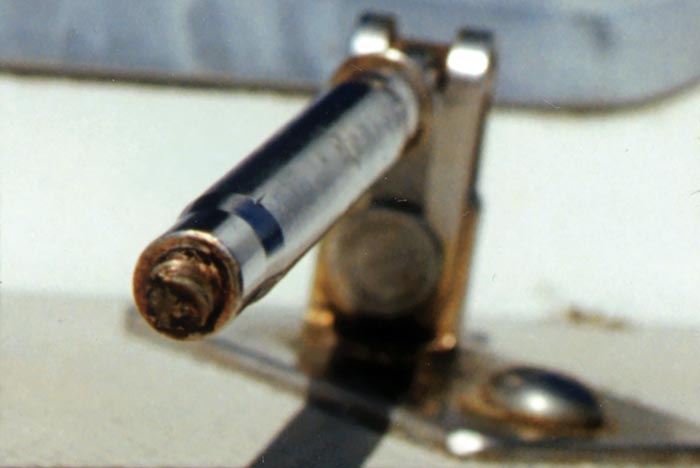

With regards to the boom, first and foremost is the gooseneck. This is a common weak spot on any rig and one that has to withstand massive forces in several different directions when under sail. If it fails it can cause considerable damage, especially if it tears itself out of the mast, which will then be severely weakened. Always remove the main pivot bolt as, though it might look OK from the outside, salt water can drip into and settle inside the guide holes, seriously corroding the bolt just where it can’t be seen.

The gooseneck may look OK but it’s best to remove the securing bolt to check it

As with all the other mast fixtures, check closely for hairline cracks around the gooseneck fitting, either on the mast or on the fitting itself. This is best done using a dye, which will help make cracks more visible to the naked eye.

Other notoriously weak points on the boom are the vang fittings. They undergo similar stress levels under way, so it’s wise to give them the same once-over as the gooseneck.

All mast attachments and their locations are worth recording

Make a rig check inventory

When inspecting your rig for the first time it’s a good idea to make an inventory of all the components and their dimensions. Use a pair of Vernier callipers to note wire and pin diameters and measure the wire lengths as accurately as possible between pin centres at each end with full tension still in the rig.

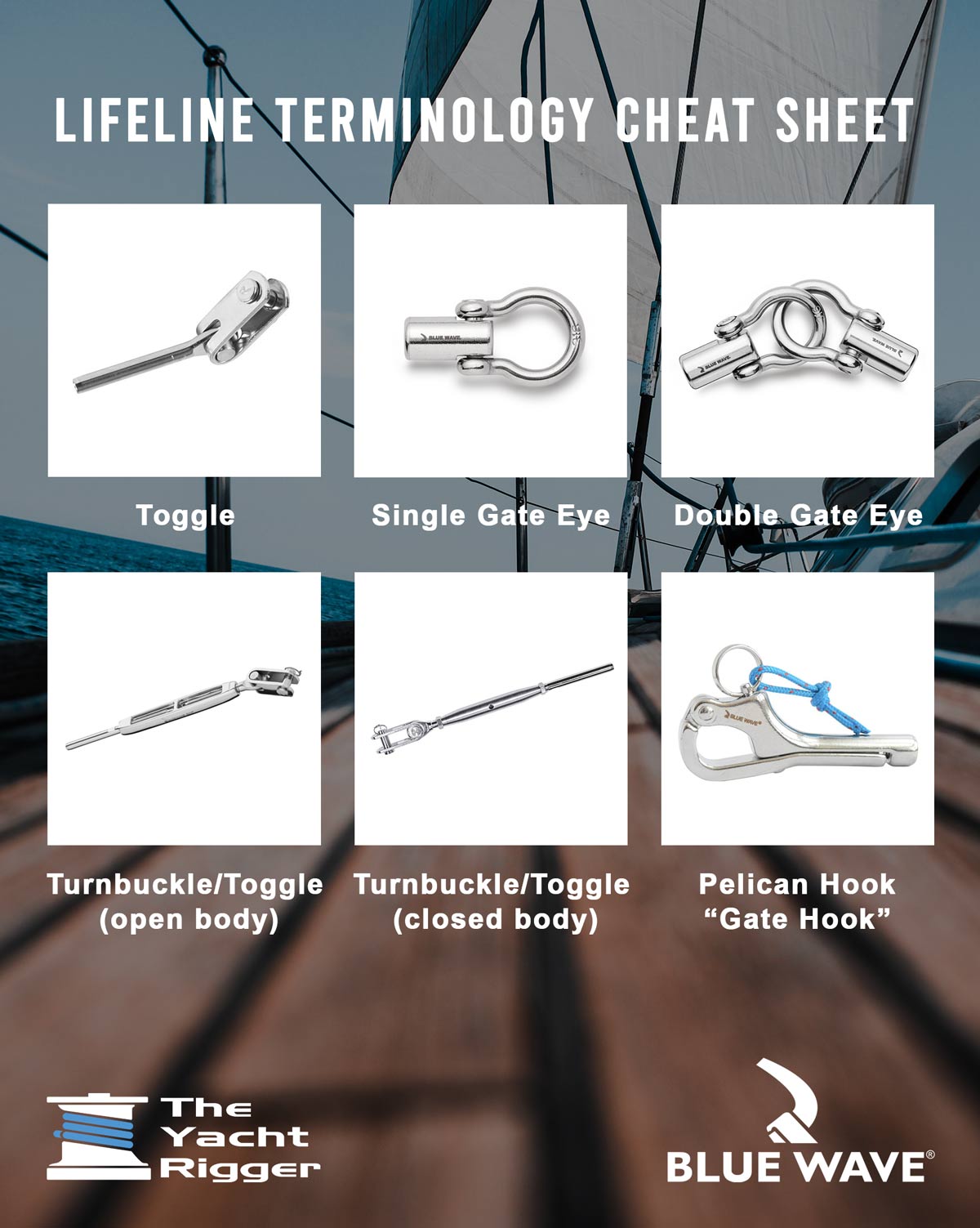

For later reference, photograph each wire end, terminal, and mast attachment. The same for the lower ends, turnbuckles, toggles, and chain plates, taking note of the positions of the turnbuckles.

If wire stretch means they’re turned up so tight as to not have any further adjustment, compensate for that in your wire length measurement if replacing. The turnbuckles should capture one third of the screw length when fully tensioned.

Check chain plates for corrosion

Turnbuckles

Back at deck-level the turnbuckles (bottle screws) and chain plates must be closely inspected for cracks, rust, wear or distortion. The former require careful scrutiny as they can often sustain damage from misalignment, particularly if a seized toggle has been preventing free movement. They can also crack under the constant tension, particularly if the rig has been pumping in rough seas.

If they have had plastic covers or been taped up there’s a good chance that trapped water might have caused corrosion, so remove and check underneath. Screw threads and locking nuts often need cleaning and regreasing. Slacken them off, giving them a few turns each way and removing clevis pins for inspection, before re-tensioning the stay and locking it off. Replace worn toggles, clevis pins, split pins or rings.

Don’t forget to uncover spreader ends to check wires and terminals

Chain plates

Finally, inspect the chain plates for cracking or distortion and tap the hull or deck around the plate lightly to and tap the hull/deck around the the plate lightly to ensure the laminate hasn’t absorbed water from leaky, dried-up sealant. Put a foot next to the chain plate and as you stand on it, check there is no flex in the deck. Go below decks, if you can, to check the bolts securing the chain plates to the hull, and now and again draw the bolts to check for cracks and corrosion. Do the same checks for forestay and backstay, especially if rust is visible. Ensuring any through-deck fittings are properly sealed will help prevent water ingress.

Choose a calm, dry day to inspect the masthead using the bosun’s chair

At the masthead

Once you’ve done all you can at deck level it’s time to go up the mast , so dig out the bosun’s chair and find a trusted mate to help. Most masts feature integral sheaves that rarely get checked during the season.

Remove the axle pins and sheaves to check for bearing wear and any flat spots that might indicate previous seizure. On reassembly replace any retaining pins or rings and ensure the sheaves spin freely.

Check for damage in the wire at the terminal end

The same goes with external halyard blocks, and you’ll also need to ensure any swivels are rotating freely. Remove any shackles, check for wear or distortion, then clean, lubricate and refasten them, replacing any that are worn or distorted.

Finally, securely seize them with new wire, ensuring there are no sharp wire ends to snag on lines or sails.

Next, check the mast fittings where backstay and forestay connect, ensuring clevis pins are straight and secure and the holes are not elongated.

Inspect the area around tang plates and toggle fittings for cracks, using a magnifying glass and dye.

Checking shroud tension with a gauge

Another common area of rig failure is where the shrouds are secured to the mast. Various connection methods are used, but all should be checked closely for wear, corrosion and/or cracking. Any sign of wear on T-ball type joints (often the indication of an under-tensioned or misaligned rig) means the terminal, socket, or both should be replaced.

Also, look to see if there is any rust or broken wires as the shroud enters the terminal. This will be easier if you slacken the tension off the wire, allowing you to wiggle the wire about.

As you work your way down the mast on the bosun’s chair, check the mainsail track is clean, straight, and well secured, giving it a good spray of track lubricant as you descend. At the spreaders inspect the roots and tips for corrosion or damage (particularly if they have plastic end caps) and ensure the spreaders aren’t bent or distorted.

Retuning the rig

When you’re happy everything is in a serviceable condition it’s a good opportunity to retune your rig, especially at the start of the season. If you do it yourself you should begin at the bottom, working your way up from the lowers, inters (if you have them), cap shrouds and finally the back- and forestays.

Adjusting the shrouds in pairs, first slacken them right off and then make a few turns on the turnbuckle one side, before going to the other and applying an equal number on the opposite shroud. Keep the balance equal on each side by counting the turns on each turnbuckle. This way you won’t risk deforming the mast or misaligning a fitting.

If you’re concerned about getting the tuning spot on, especially if racing is your thing, then it’s probably worth investing in a rig tension gauge such as a Loos gauge so you can tune your boat rigging effectively.

Yacht rigging Inspection checklist

- Mast and boom for cracks and corrosion

- Spreader roots and ends for damage

- Integral masthead and boom sheaves for seizures and flat spots

- Corroded or broken shroud wires

- Cracked, seized or rusty turnbuckles

- Toggles for wear and distortion

- Alignment of shroud fittings

- Furler and swivel bearings for wear and lubrication

- All shackles for wear and distortion, replacing seizing wire

Rig maintenance tips

- Ensure any taping of screws or pins cannot trap water, which will in time cause corrosion

- If you are taping over sharp edges, self-amalgamating tape will last longer than electrical tape

- Wash all moving parts with fresh water to remove salt residue

- Use a silicone-based lubricant regularly to keep moving parts free-running

- Avoid contact between dissimilar metals – use an anti-corrosion paste when using screws or rivets, and use plastic tape to create a barrier layer between fittings

- Rake out and renew sealant around through-hull fittings to prevent water ingress. If you are taking your rig down, take the opportunity to remove deck fittings and re-bed on new sealant

- Get your rig professionally inspected every three years, and let your insurance company know you’ve had the all-clear

Enjoyed reading this?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

How to Inspect and Tune a Sailboat Rig

- By Ralph Naranjo

- Updated: May 14, 2020

Major mast failures usually begin as minor hardware problems. At least that’s what scrap-bin forensics seems to confirm. So, instead of dreading a dismasting, prevent it with a sensible approach to rig maintenance.

Some sailors inspect their masts and rigging with the spar stepped, but most recognize how much will remain unseen. Riggers recommend that the mast come out every few years and be placed on a pair of sturdy sawhorses ready for close-up scrutiny. My DIY approach focuses on hardware junctions and points where load paths intersect. Packed in my rigger’s bag are the usual hand tools, plus a Scotch pad, a quality magnifying glass and a small digital camera to record the findings. The old rule of thumb is that standing rigging has a decade’s, or one circumnavigation’s, worth of reliability; it’s a benchmark that remains valid today.

Another important issue is the rigging’s designed safety factor, or how much stronger the components are than they need be. The catch here is material deterioration over time, and the fact that there’s a direct correlation between stronger structures and increased reliability. For example, by increasing 1-by-19 shrouds and their attendant hardware from 5/16 inch to 3/8 inch, the higher safe working load translates into a longer life span. It’s a legit assumption, but doing so is both costlier and adds weight aloft, which can rob performance. The same tenets apply for a larger-diameter spar section and greater wall thickness. Engineers and naval architects try to balance these competing factors.

Some decades ago, I watched the deck-stepped spar of my first little cruising sloop drop into the drink. It drove home the fact that it really is the little things that count. In that case, it was a stainless- steel toggle, connected to an upper shroud turnbuckle, which had endured a few too many on-off load cycles. A tiny, nearly invisible crack had opened up, and salt spray had found a new home. The resulting corrosion tipped the scale and led to a dramatic failure. Since then, rig scrutiny has become my obsession.

The old rule of thumb is that standing rigging has a decade’s, or one circumnavigation’s, worth of reliability.

Wire and rod end fittings need a close look, especially in areas where there are brown stains and signs of cracks, pitting or other surface deterioration. This includes an evaluation of clevis-pin holes that should be circular, not elongated. Confer the same level of scrutiny to the clevis pins themselves. Don’t confuse stainless-steel clevis pins with chrome-plated bronze pins. The latter are just fine when used in bronze fittings, but when a bronze clevis pin is placed in a stainless-steel chainplate hole, the bronze pin can be carved away by the much harder stainless-steel chainplate.

My inspection process includes a rigging-wire wipe-down with a rag that easily snags on tiny cracks. It includes careful scrutiny of hardware junctions. I search for signs of chafe, especially where fiber or wire running rigging makes directional changes at sheave boxes, and around where the headsail furler’s top swivel rides. Looking closely at masthead exit points, I check for sheave wobble, excess side play and signs of pulley damage.

This is also the time to sort out halyards that are rubbing against external or internal obstructions. I use a bright, narrow-beam LED flashlight for a good visual inspection of the internal portion of the mast. Not only will it pinpoint screws and sheave boxes that might be causing chafe, but it also will help you untangle crossed halyards and confirm fairleads. While working at the heel end of the spar, look closely for corrosion and a condition riggers call “elephant foot.” It’s an actual wrinkling of the alloy tube section caused by too much compression and a too-thin wall section. It’s most often seen on raceboats with powerful hydraulic mast-adjusting systems, and on cruising boats that have pounded into too many steep wave faces.

Roller furling foils hide the wire or rod on which they spin. Rigging end fittings and terminals can usually be inspected, but a broken strand of wire inside the foil might initially go unnoticed, at least for a little while. This is another reason why offshore cruisers opt for a cutter or solent rig that adds a second stay for some extra insurance. Following the once-a-decade rule, it makes sense to completely disassemble furling systems, and replace the wire along with any worn bearings, bushings or plastic spacers.

My inspection process includes a wire wipe-down with a rag that easily snags on tiny cracks. I search for signs of chafe everywhere.

Keep in mind that when the mast is unstepped, many roller furling drums and head foils (especially on boats with deck-stepped rigs) extend beyond the heel of the spar. If the yard doesn’t splint and immobilize the extended foil and drum, do it yourself. All it entails is a couple of 2-by-4’s, or a pair of old oars lashed or duct-taped to the mast just above the heel. This double splint should extend to the base of the roller-furling drum where it too is lashed or taped. It keeps the drum from dangling and bending the foil during transport, and while the rig is stored on a mast rack.

Spreaders also deserve a really close look. All too often, excess anti-chafe protection results in the spreader tips becoming a water trap that turns into a hidden corrosion bath. So, when the rig is down, cut away the spreader-tip padding, and use white vinegar and a plastic scrub pad to get rid of any white powdery oxidation. Remove the spreaders from the spar, and inspect the area where spreader bases make contact with the mast. Look for compression damage to the mast wall and signs of corrosion damage. If all is well, reassemble using one of the tried-and-proven water-resistant lubricants. I’ve settled on Lanocote, McLube Sailkote and Super Lube, using Boeshield T-9 and WD-40 as my go-to spray protectant and penetrant. Throw away the old cotter pins, and use new pins on all of the reassembled rigging.

“She’ll be right, mate,” was the favorite phrase of an old Kiwi friend, but it isn’t good advice when it comes to keeping the rig where it belongs. Don’t shy away from calling in a qualified rigger to handle larger problems.

Most boatyards will restep spars but won’t tune the rig. Their goal is to set up the mast and rigging to approximate how it arrived. Occasionally, they hit the mark and even replace the mast wedges appropriately. Otherwise, I wait for a flat calm to make sure that the boat has no list. This involves using a tape measure to confirm the athwartship trim (waterline to rail-height port equals waterline to rail-height starboard). Then I check the perpendicular and rake of the mast using the main halyard with a makeshift plumb bob (dive weight) attached. The retune requires loosening the turnbuckles and incrementally retensioning the rigging. Small amounts of headstay and backstay adjustment relocates the masthead, causing the makeshift plumb bob to move significantly. I use prior measurements from previous mast-tuning successes to set the rake to a sweet spot that, in the past, delivered a minimal amount of weather helm.

With the rake set, I insert a set of teak or high-density hard-rubber wedges between the mast and the mast partners. These wedge-shaped spacers have a top flange that prevents them from falling into the bilge when the mast compresses on one side of the partners and opens the gap wider on the other. With all the wedges set, I incrementally add tension to the rig, tightening headstay and backstay first, while carefully maintaining the rake angle. Next, I adjust the upper shroud (or V1), working from side to side to keep the mast perpendicular. Finally, I snug up (but not overtension) the lower and intermediate shrouds. This static tuning sets the stage for an underway final tune, during which I check how well the spar remains in column. Leeward bends and S-curves are problematic and must be minimized. Boats with discontinuous rigging have shrouds that are not one continuous wire run. They utilize turnbuckles located above spreaders that must be individually adjusted to eliminate side bend.

During sea trials, make sure the leeward standing rigging is not overly slack and flopping around like loose spaghetti.

Intentional fore and aft mast bending can influence sail shape, and is put to good use aboard raceboats. Adding such complication to most cruising boats, which are normally steered by an autopilot, makes less sense. In-mast furling spars are least happy with powerful hydraulic backstays bowing the mast. So, get sound advice from a rigger/mast builder before adding hydraulic sail-shaping gear.

A sea trial should follow your static mast tune. And as you beat to windward in a modest 10- to 15-knot true breeze, check the leeward standing rigging. Make sure it’s not overly slack and flopping around like loose spaghetti. If so, add more shroud tension to both sides. A tension-testing gauge will work, but many sailors do fine estimating by hand. Cruising-boat rigs shouldn’t have the same amount of rig tension as a raceboat beating to windward. However, if your sailboat’s mast is deck-stepped, make sure the coachroof isn’t deforming due to the compression load. A compression post, ring frame or other rigid structure should be spreading such loads. If you’re unsure of the correct rig tune, arrange a session with a rigger or sailmaker—and start the season in optimized trim.

Technical expert Ralph Naranjo has inspected the rig on his Ericson 41, Wind Shadow , on countless occasions.

- More: fitting out , hardware , How To , mast , rigging

- More How To

3 Clutch Sails For Peak Performance

It’s Time to Rethink Your Ditch Kit

8 Ways to Prevent Seasickness

How To De-Winterize Your Diesel Engine

The Moorings Expands in Croatia

C-Map Updates North America Charts

New to the Fleet: Italia Yachts 12.98

St. Vincent Court Orders Deportation For Hijacking Suspects

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Cruising World

- Florida Travel + Life

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Many products featured on this site were editorially chosen. Cruising World may receive financial compensation for products purchased through this site.

Copyright © 2024 Cruising World. A Bonnier LLC Company . All rights reserved. Reproduction in whole or in part without permission is prohibited.

Service Locator

- Angler Endorsement

- Boat Towing Coverage

- Mechanical Breakdown

- Insurance Requirements in Mexico

- Agreed Hull Value

- Actual Cash Value

- Liability Only

- Insurance Payment Options

- Claims Information

- Towing Service Agreement

- Membership Plans

- Boat Show Tickets

- BoatUS Boats For Sale

- Membership Payment Options

- Consumer Affairs

- Boat Documentation Requirements

- Installation Instructions

- Shipping & Handling Information

- Contact Boat Lettering

- End User Agreement

- Frequently Asked Questions

- Vessel Documentation

- BoatUS Foundation

- Government Affairs

- Powercruisers

- Buying & Selling Advice

- Maintenance

- Tow Vehicles

- Make & Create

- Makeovers & Refitting

- Accessories

- Electronics

- Skills, Tips, Tools

- Spring Preparation

- Winterization

- Boaters’ Rights

- Environment & Clean Water

- Boat Safety

- Navigational Hazards

- Personal Safety

- Batteries & Onboard Power

- Motors, Engines, Propulsion

- Best Day on the Water

- Books & Movies

- Communication & Etiquette

- Contests & Sweepstakes

- Colleges & Tech Schools

- Food, Drink, Entertainment

- New To Boating

- Travel & Destinations

- Watersports

- Anchors & Anchoring

- Boat Handling

Inspecting Your Boat's Mast and Rigging

Advertisement

Keep your sailboat in top shape with this useful advice on inspecting your boat's mast and rigging.

Surveying Your Rig

What to look for and why.

Whenever a mast tumbles overboard, the two seemingly obvious offenders are the mast itself — the aluminum extrusion — and the wire stays and shrouds that support the mast. In practice however, these are rarely the culprits. The offenders, in most cases, are the tangs, turnbuckles, and chainplates and the smaller, but no less significant, screws, bolts, terminal fittings, clevis and cotter pins that hold everything together. These can be inspected in a couple hours or less. All you need for an inspection is a magnifying lens, a mirror, some toilet paper, your fingernails, a boatswain's chair, and a pair of reasonably good eyes.

Download the Rigging Checklist in PDF format.

Whenever you inspect a fitting, look for obvious problems like rust and distortion and use the magnifying glass to find smaller cracks. Rust, especially rust that you can feel, and even slight distortions or cracks should be considered serious, and the component replaced. Use your fingernails to feel for cracks and check the thinnest part of the fittings extra carefully, as this is where failure is most likely to occur. If a fitting has been painted (a bad idea), strip off the paint.

Chainplates

Turnbuckles and chainplates must be angled so that loads are in a direct line with stays and shrouds. Toggles, which act like universal joints to allow movement in all directions, should be used with turnbuckles but they cannot be relied on to compensate for a misaligned chainplate. A chainplate that is not aligned has a tendency to work until it eventually breaks. Besides eyeballing the shroud/chainplate alignment, misalignment is sometimes indicated by damage to the surrounding gelcoat.

Chainplates can corrode and fail either above, within, or below the deck. Corrosion at the chainplate above may have been only detected by removing the toggles to inspect around the eye.

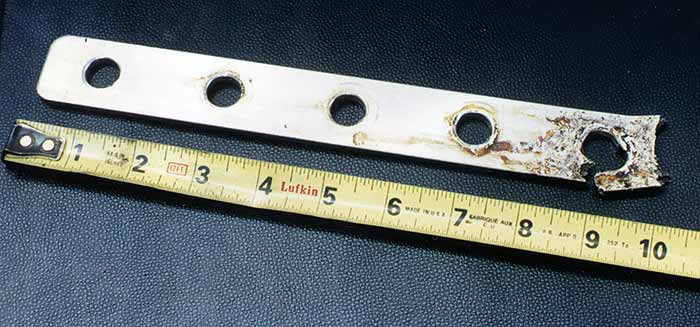

The chainplate above failed within the deck, where salt water had leaked down and initiated crevice corrosion where hidden from view.

If chainplates are bolted to a bulkhead, as is often the case, inspect the bulkhead for signs of weakness — discoloration, delamination, and rot. Chainplates are highly stressed, and will work and cause leaks where they come through the deck. Water can then enter the bulkhead and eventually cause it to rot. Probably the best, although maybe not the prettiest, place to secure a chainplate is to the outside of the hull. Chainplates that are only bolted to flanges under the deck, and are not secured to a structural member down below, are the least desirable installation.

Turnbuckles

Open turnbuckles are easier to inspect and don't retain moisture, which encourages corrosion. Closed turnbuckles retain moisture in the barrel and have of a tendency to freeze up, but they also are better at retaining lubricant.

Fatigue and crevice corrosion broke this pair of threaded terminal fittings along the crevice between the lock nut and the turnbuckle body, illustrating why disassembly of the turnbuckle is necessary to inspect hidden trouble spots most likely to fail.

Turnbuckles should be wiped clean and lubricated at least once a year; more often if they are open or are adjusted frequently.

Teflon is better for lubricating turnbuckles than oil or grease because it doesn't hold grit that abrades the threads. Oil or grease, however, are certainly better than nothing.

Most turnbuckles are tightened by turning the shank or barrel clockwise. Incidentally, you should never stress your rig by over-tightening the turnbuckles. If the turnbuckle squeaks stop tightening — this is a sign of over-tightening and poor lubrication.

If you boat has open turnbuckles, be sure to leave at least 3/4" of thread visible in the barrel and replace the old cotter pins. A cotter pin should be large enough to fit snugly into the hole and long enough to be bent half way back around. Rigging tape should then be wrapped around the pin to protect your sails, fingers, toes, etc.

Many closed turnbuckles can't be cottered and rely instead on locknuts. Experts warn that over-tightening the locknuts places too much stress on the threads.

Terminal Fittings

Most sailboats rely on swage fittings at the terminals, but these fittings are not necessarily the most reliable, especially in warmer climates where they have a history of failure. Swage fittings are made by compressing a tube onto the wire under great pressure, a process that must be done exactly right to assure a strong bond. If the swage has to be pressed several times (a bad practice) before the wire is secure, there is an increased chance that the swage has been weakened and could crack.

There are other types of terminal fittings, such as Noresman and Sta-Lok, which are more expensive and less common than swage fittings but are highly touted by many sailors for their durability. Norseman and Sta-Lok fittings can be installed or repaired by the boat owner — an obvious advantage, especially for making emergency repairs on long cruises.

Cracked swage fittings are not only the most common kind of rigging failure, but also the most visible. This one should have been noticed and replaced long ago.

Careful inspection of all terminal fittings is a must. Cracks are usually microscopic when they begin, so use your magnifying glass. Also, you can sometimes feel a crack with a fingernail that cannot be seen.

Cleaning the fitting with metal polish helps brighten the fitting to make inspection easier and using one of the three-part spray products on the market also helps you see cracks. The latter are highly touted by their manufacturers but they are not infallible. The first part cleans the fitting; the second part is a dye that penetrates the crack; and the third part is a developer. The dye, incidentally, can stain gelcoat, so be careful.

Terminal fittings, especially swage fittings at the deck, are prone to rust where the wire enters the swage. Rust indicates a serious problem and the swage and possibly the wire should be replaced. Some skippers like to use gel or wax to prevent water from entering the swage. While this may be effective for a while, it probably won't keep water out for long and could very well trap water inside, encouraging corrosion.

The Mast and Boom:

Welds and rivets.

Aluminum welds on the mast and boom should be inspected, especially where there may be a lot of stress. Look at the ends of the welds first, as aluminum welds fail from the ends of the weld inward. Welds that are not done correctly have sharp edges and crevices which encourage corrosion. Any welds that are cracked or badly rusted should be rewelded immediately.

Rivets should be examined, and any that are loose or missing should be drilled out and replaced with the next-larger size. Also, if one or two rivets holding a cleat or gooseneck are loose, it is a good idea to replace all of the rivets with the next-larger size, not just the ones that are missing.

Galvanic Corrosion

Galvanic corrosion occurs when stainless steel or bronze fittings — cleats, tangs, winches — are installed metal-to-metal on an aluminum mast.

Every few years, mast fittings should be rebedded with zinc chromate paste, polysulfide, teflon, nylon, or tufnol (plastic) to protect the mast from galvanic corrosion. Silicone does a good job of protecting the mast, but the fittings may be difficult to get off later. And in a pinch, Rolf Bjelke aboard the steel ketch Northern Light in the Antarctic, used a plastic coffee can lid to bed a halyard winch.

If a mast is painted, look for bubbles near fittings, which indicate corrosion. On an unpainted mast, look for white powder and pockmarks around fittings. Some powder, which is oxidized aluminum, is normal on an aluminum mast and is usually not significant. But heavy concentrations of powder, bubbles and/or pockmarks, especially deep pockmarks, indicates a serious problem that threatens the integrity of the rig. Contact a rigger or surveyor if you suspect a problem.

Whether it is stepped on deck or on the keel, the base of a mast — a maststep — should be the same material as the mast. Because water that is outside the boat usually finds its way into the bilge, a mast that is stepped on the keel is especially prone to corrosion when the boat is used in saltwater. A rigger in Maryland likes to tell the story about an owner who complained that the stays and shrouds that couldn't be tightened. He thought they had stretched. It turns out that the maststep had corroded so badly that the mast was "sinking" into the bilge.

A mast that is stepped on deck can cause problems if the load isn't supported properly down below. This is sometimes a design problem, but most often it is because a bulkhead or support stanchion has failed — shifted, rotted, delaminated, etc. Look down below for indications of movement, including jammed doors, broken bonds, and splitting wood. A sagging cabin top is a strong indication that adequate support isn't being provided.

Besides corrosion, maststeps can be damaged when the mast is cocked to one side and the heavy compression load is not evenly distributed. Indications of uneven compression load include cracking and/or crushing of the mast's base. The problem can be avoided by keeping your rig tuned — adjusting the stays and shrouds to make the mast straight. If the base of the mast has already been damaged, don't despair, it can either be cut down slightly and restepped or, if the problem is more serious, the damaged portion can be cut down and an extrusion added. Either way, the boat should not be sailed until a rigger is contacted and the problem has been corrected.

Wood masts have a lot of eye appeal but require more upkeep than aluminum masts. Wood masts are usually made of spruce, a material that is light and flexible, but prone to rot.

Rot is easier to detect when a mast is varnished. Painted masts hide rot, but only for awhile. Any areas that are badly discolored on a varnished mast, or won't hold paint on a painted mast, are suspect and should be sounded with a hammer for indications of soft wood. Rot is most likely to appear around fittings, the masthead, mastboot, spreaders, and especially at the maststep. These areas should be inspected twice a season and treated or caulked as necessary. Weep holes, used to drain water at the base of a box mast, can become plugged with debris, leaving water to fester inside the mast. Weep holes should be checked periodically with a coat hanger to prevent blockage.

Inspecting Aloft

Most people have a natural aversion to hanging from a rope at the top of a swaying mast. If possible, inspect your mast while it is unstepped. If you do go aloft, make sure there are experienced hands below to hoist you up. A snap shackle, if one is used on the halyard, can be made safer by taping the lanyard to prevent its accidentally opening. Also, if the boat is in the water, you'll want to moor it where it won't get tossed around by a passing boat wake.

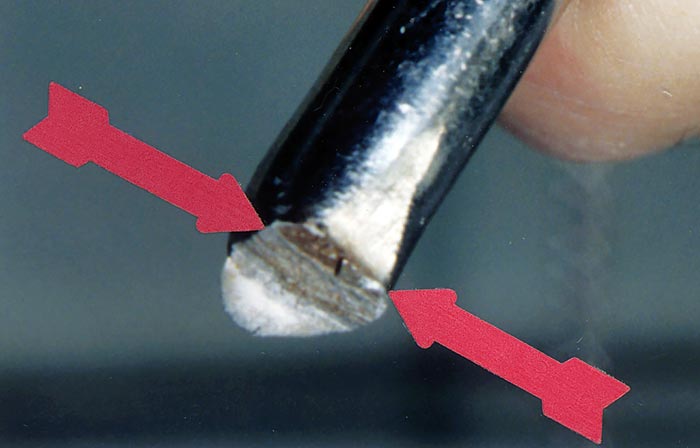

Stress cracks often form at bends of fittings, such as the under side of upper T-ball terminals.

Zero in with a magnifying glass to detect cracks and discoloration before they fail.

Take tools: screwdrivers, pliers, a small hammer, lubricant, the mirror, extra cotter pins, and rigging tape. Put them all in a tool pouch or boatswain's chair with tool pockets and Velcro flaps. Whenever possible, use lanyards on the tools. The only thing worse than making the crew haul you up and down the mast getting tools you forgot is to drop a tool on someone's head. (You can also help the grinder's morale by using your feet and hands to help hoist yourself up.)

First stop is the spreaders. (While you're working, have the tailer cleat-off the halyard.) Make sure the ends of the spreaders bisect the shrouds at equal angles and are secured properly to prevent slipping. Skewed spreaders have been responsible for many dismastings. Tape or spreader boots, used on the spreader ends to prevent damage to the sails, should be removed temporarily so that the spreader ends can be inspected and the connection tightened as necessary.

Some skippers paint the top of the spreaders, even aluminum spreaders, to reduce damage from sunlight. This is a necessity with wooden spreaders, unless you go aloft every month and add a coat of varnish. Remember, you can't see the tops of the spreaders from down below.

Like their counterparts the chainplates, fork tangs, used to secure the shrouds to the mast, should be angled so that loads are in a direct line with stays and shrouds. Cotter pins should be taped so that they don't shred flailing sails or snag a halyard. Shrouds that use "T" terminals should be examined for stress cracks where the bend occurs and for elongation of the slot. Either problem indicates the shroud or fitting should be replaced.

The last stop, before you begin your descent, is the masthead. If you are even slightly acrophobic, the masthead can be a very scary place. Avoid looking down.

The mirror (remember the mirror?) is especially useful for inspecting fittings at the masthead that would otherwise be inaccessible. Look at the halyard fittings, especially the sheaves, which wear over time and can be crushed or split by the strain of the genoa. Even if it's healthy, a squirt of two of lubricant can help whenever the sail is raised. Wind indicators and radio antennas should also be checked for loose mounts and connections.

On the way down check the rivets and/or screws used to secure the mast track. Replace any that are missing or suspect. While you're at it, you may as well lubricate the track (use teflon) to make raising and lowering the sail less of a chore.

Standing Rigging: Stays and Shrouds

Stays and shrouds should have some "give", but not too much, when pressure is exerted with the palm of your hand. A stay that is too tight feels rigid. A stay that is too loose feels limp. Make sure any necessary adjustments are done evenly so the mast doesn't get cocked to one side. And adjustable (mechanical or hydraulic) backstays should be slackened when not in use. Remember, turnbuckles should have sufficient thread inside the barrel — at least 3/4" — and cotter pins to prevent their coming loose. (Be sure and wrap fresh tape around the cotter pins when you're done.)

This is what 1x19 wire looks like at the upper headstay terminal fitting after it has been twisted back and forth a few times from "halyard wrap". Even slight damage from minor episodes warrants replacing the wire.

Wire should be inspected for broken strands or "fishhooks" by wrapping some toilet paper around the wire and running it up and down. If the paper shreds, the wire is nearing the end of its useful life and should be replaced. Check the wire where it enters the swage fittings for rust, which also indicates weakened wires that should be replaced.

Replace Your Standings Rigging: $$$?

Lets play "what if". What if a small voice inside you says your rig is living on borrowed time: you've found rust, cracks, failed welds, and fishhooks?

As a general cost guideline, replacing the standing rigging on a typical 30 footer with 1/4" wire rigging will cost about $1,200. That price includes turnbuckles but not unstepping the mast. The cost of replacing the standing rigging on a 40-foot cruising boat with 3/8" wire could be almost twice as much. Incidentally, it pays to get estimates, as prices can very significantly. Our estimates to replace the standing rigging on a 30-foot boat, for example, were as high as $2,800.

Professional Inspections

If you're not confident in your ability to inspect your boat's rig, you can hire a professional — a rigger or surveyor — to do it for you. Riggers specialize in rigging, which is an advantage, but they could be biased since they also sell rigging. An inspection, including going aloft, should be under $100 for a 30' boat.

Related Articles

The truth about ceramic coatings for boats.

Our editor investigates the marketing claims of consumer-grade ceramic coatings.

Fine-Tune Your Side Scan Fishfinder

Take your side-scanning fishfinder off auto mode, and you’ll be spotting your prey from afar in no time

DIY Boat Foam Decking

Closed-cell foam flooring helps make boating more comfortable. Here’s how to install it on your vessel

Click to explore related articles

BoatUS Editors

Contributor, BoatUS Magazine

Award-winning BoatUS Magazine is the official publication of Boat Owners Association of The United States. The magazine provides boating skills, DIY maintenance, safety, news and more from top experts.

BoatUS Magazine Is A Benefit Of BoatUS Membership

Membership Benefits Include:

Subscription to the print version of BoatUS Magazine

4% back on purchases from West Marine stores or online at WestMarine.com

Discounts on fuel, transient slips, repairs and more at over 1,200 businesses

Deals on cruises, charters, car rentals, hotel stays and more…

All for only $25/year!

We use cookies to enhance your visit to our website and to improve your experience. By continuing to use our website, you’re agreeing to our cookie policy.

Rig check – how to prevent failure at sea

by Simon Jollands | Boat Handling , Boat Maintenance , Preparation

Regular rig checks prevent the risk of mast and rigging failure at sea. This includes regular rig inspections of the spars, rigging and fittings, especially before a major passage at sea.

Most rig failures are caused by poor maintenance and breakage of the fittings and connectors, especially those that attach the shrouds to the mast, rather than the actual spars or rigging themselves failing. A quick visual rig check is sometimes all that it takes to deal with a potential problem. However, attention must also be given to reducing metal fatigue through correctly adjusting and tuning the rigging.

Rig inspections

A more thorough inspection of a yacht’s spars and rigging should be carried out at regular intervals by a trained rigger, ideally on an annual basis, or as recommended by the manufacturer. It is also advisable to do an inspection before a major sea passage. The inspection will comprise a visual inspection, sometimes aided by ultrasound tools, where wear is recorded and monitored for future inspections. The inspection will look for items such as cracks in rigging components, misalignment of stays and corrosion. Rig tensions should be checked and adjusted as necessary. A written record should be completed listing existing or potential concerns.

Every 5 years or so, more thorough rig checks should be carried out, which involve disassembly of the rig. This may include Dye Testing or Liquid Penetration Inspections which reveal surface flaws not visible to the naked eye.

Here’s a useful checklist of things to look out for that we’ve put together with the help of the KZ Marine Group in Auckland, New Zealand:

- Deck check – split pins, adequacy of threaded fittings, chafe or breakage of stranded wires, rig cracking, rust streaking, condition of mast collar sheaves, halyard alignment, halyard chafe guards, forestay condition.

- Masthead – halyard sheaves rotate freely and are sound, bushes, split pins intact, electrical wires are clamped correctly and are chafe free, lights are operating, halyard shackles in good condition, Windex and wind gear operating correctly.

- Forestay – roller furling headstay, halyard leads at correct angle to swivel car, inspect halyards for wear on sheaves, fairleads and check swivel cars, mast tang pin hole, corrosion around mast tangs, threaded fittings, no broken strands of wire, signs of cracking or rust.

- Mast stay wires and mast fittings – no broken strands of wire, no visible signs of cracking along swage section, no signs of rust streaking, Tbar plates have retaining plugs or locking tabs, corrosion around mast tangs, fastenings secure, threaded fittings are sound, rigging screws locked.

- Spreaders – no visible signs of cracking , fastenings secure, no signs of rust streaking, broken wire strands, lights are working, wires clamped correctly, no chafe, no corrosion,

- Gooseneck, Vang and Knuckles – check for signs of corrosion, split pins are protected to safeguard sails, fastenings secure, excessive wear or elongation of fittings.

- Chainplates – check for excessive wear on spacers or bushes, signs of elongation in pin holes, alignment with stay angles, evidence of fracture at deck level, are fastened securely below deck to the hull.

- Spinnaker pole ring – attachment points secure, signs of corrosion around mast tangs.

- Insulators – check for sunlight degradation of plastic insulators, aerial wire securely fastened and in good condition.

[fts_facebook type=page id=820902544629856 access_token=EAAP9hArvboQBAMMusRb1XctIwYq9fUcSZCVNDQAMjkZCiqAIMiZBkawPJZB3VkeSsH6gCIDfIZAslzZBRAEXYdesg0fu11YIst1FXtABBwdULjOsYFGUYqNujLSxRIWxKAcqm7bb9dmAgzJDZCVhkRj6r9useCQqJr4wJnxkBv909ySYxqj7hYl posts=4 height=650px description=no posts_displayed=page_only]

Recent Posts

- DIY boat upgrades: Budget-friendly projects to enhance your (older!) boat

- Boat Security: Protecting your vessel from theft & vandalism

- Learning about diesel engine maintenance

- 2023 Rolex Fastnet Race – Part 3

- The dangers of running aground in a motor boat

- (954) 633-4878

- [email protected]

Compass Articles

- December 4, 2023

Yacht Rigging and Sails: Regular Care and Inspection

As a vessel carves its path through the winds and waves, its rigging and sails are the silent workhorses of performance and progression. At Fly Yachts , we bring our commitment to excellence to every aspect of yacht care, including the vital components above deck. Maintaining the rigging and sails through regular care and inspection is imperative for safe, optimal performance. Join us as we navigate through the best practices for maintaining these crucial elements for your yachting adventures.

The Symphony of the Masts: Rigging Maintenance

The rigging of your yacht demands precise attention to detail:

- Conduct visual inspections of all standing rigging components for signs of wear, corrosion, or damage.

- Check for loose fittings, clamps, and screws, properly securing them and replacing where necessary.

- Apply lubricants to moving parts such as sheaves and furling systems to ensure seamless operation.

Fly Yachts underscores the importance of thorough rigging care for harmonious voyages across the sea.

The Canvas That Catches the Wind: Sail Care

Sails, the very embodiment of seafaring heritage, require dedicated preservation efforts:

- Inspect sails regularly for any tears, abrasions, or stitching issues, making repairs promptly.

- Clean sails with appropriate solutions and techniques to prevent mildew and UV damage.

- Properly flake or roll sails for storage, avoiding unnecessary creases or stress points.

Our knowledge at Fly Yachts extends to the nuanced care of these majestic fabrics that animate your yacht.

Ropes and Lines: The Veins of Vessel Control

The diverse array of ropes and lines are the veins that channel control throughout your craft:

- Rinse ropes with fresh water to remove salt crystals and prolong their lifespan.

- Examine the outer sheath and inner core for any signs of deterioration or excessive wear.

- Store lines neatly, coiled or flaked, to avoid kinks and facilitate immediate usage.

Fly Yachts shares expert tactics for rope maintenance, safeguarding your mastery over the yacht’s command.

Life Among the Hardware: Inspecting Blocks, Winches, and Cleats

The deck hardware stands as a silent sentinel, ready for action:

- Inspect blocks for smooth pulley action and ensure they’re free of debris and corrosion.

- Service winches periodically by disassembling, cleaning, and lubricating.

- Check cleats and winch bases for any signs of loosening or wear and secure them firmly.

With Fly Yachts , rest assured every component is prepared to serve its critical role in every maneuver.

The High-Fliers: Inspecting Spars and Spreaders

The spars and spreaders, soaring high, bear witness to the sky’s moods:

- Ensure that spars are free of corrosion, particularly aluminum masts susceptible to galvanic action.

- Inspect spreaders for signs of damage and ensure that their angle and position are optimized for sail shape.

- Consider professional rig inspections at regular intervals, especially after challenging voyages or at the turn of the seasons.

Fly Yachts advocates for elevated levels of care, keeping the integrity of your yacht’s vertical components in check.

The Stitch in Time: Sail Repair and Seasonal Service

Sail service shouldn’t be reserved for evident damage alone:

- Allow a professional sailmaker to inspect and service your sails annually.

- Discuss sail optimization for performance or enhanced durability with your sail care provider.

- Address any potential issues early to avoid costly repairs or replacements down the line.

Fly Yachts suggests a proactive stitching strategy to ensure that your sails remain robust and effective.

Harnessing the Wind with Confidence

A well-maintained rigging and sail setup offers more than performance – it offers peace of mind:

- Utilize calm days for practice drills to familiarize the crew with rigging and sail handling.

- Engage in a routine schedule of care, ensuring your yacht is always prepared for the winds ahead.

- Keep detailed records of inspections and maintenance for a clear history of your yacht’s care.

Expert guidance from Fly Yachts ensures that every journey undertaken is backed by meticulous preparation and knowledge.

Conclusion: Sustaining Elegance and Power with Fly Yachts

The majesty of a yacht under full canvas is a sight that inspires awe and symbolizes freedom. Through disciplined care and regular inspection of rigging and sails, Fly Yachts steers owners towards a harmonious relationship with the forces of nature. For a tailored plan in maintaining these performance elements, consult with a Fly Yacht team member today.

Setting Sail with Assurance

Trust in Fly Yachts to cultivate the resilience and elegance of your yacht’s upper deck apparatus. By placing your rigging and sails in our capable hands, you are assured that every journey begins and ends with the unmatched splendor that can only be delivered by well-maintained equipment.

Fly Yachts’ Frequently Asked Questions

Why is regular rigging and sail maintenance important.

Maintaining rigging and sails ensures performance, safety, and longevity.

How often should yacht rigging be inspected?

Inspect rigging biannually and after heavy sailing or severe weather.

What are the signs that sails need repair or replacement?

Look for tears, stretching, discoloration, and hardware wear.

Can Fly Yachts handle rigging adjustments and tuning?

Yes, we provide professional rigging services, including adjustments and tuning.

How can I extend the life of my sails?

Avoid overloading, rinse with fresh water after use, and store dry.

What should I look for during a rigging system check?

Check for corrosion, damaged wires, loose fittings, and worn components.

Are there best practices for cleaning sails?

Use mild soap, avoid strong detergents, and rinse thoroughly with fresh water.

How do I prevent mildew on stored sails?

Ensure sails are bone dry before storage and keep them in a well-ventilated area.

What maintenance is required for sail attachment points?

Regularly inspect for wear, lubricate moving parts, and replace damaged hardware as needed.

Does Fly Yachts offer sail repair and maintenance services?

We provide sail inspections, repairs, cleaning, and preservation treatments.

At Fly Yachts, we offer a sweeping selection of yachts for sale , from the grandeur of super yachts to the bespoke appeal of center consoles, designed to resonate with a range of seafaring preferences. Navigate through our homepage and discover our full spectrum of services, showcasing our dedication to high standards in the yachting and aviation sectors. Visit our About Us page to learn about our rich history, expert team, and what makes us a leader in luxury yachting. The Build a Yacht page invites those with a vision for their custom vessel, offering numerous personalization options. Travelers can select their ideal yachting destination from our comprehensive Charter Destinations list. Our Compass Articles provide an array of insightful content for yachting enthusiasts of all levels. Yacht owners looking to sell can benefit from our tailored Sell Your Yacht services. For those planning a refined vacation on the water, our Yachts Charter options ensure a luxurious experience. And for those interested in aviation, our Aircraft for Sale page highlights a fleet of elite aircraft available for purchase. Stay informed on current yachting news with Gulfstream News , and if you require assistance or have any inquiries, our Contact page links you directly with our knowledgeable Fly Yachts team.

About FLY Yachts

Unmatched Industry Knowledge, Paired With Brokers Who Care Equals Yachting You Love.

Recent Posts

Yachting’s Hidden Gems: Lesser-Known Luxuries of the High Seas

Seafaring in Style: The Influence of Global Fashion on Yacht Design

The Golden Age of Yachting: Reflecting on a Century of Nautical Excellence

All Right Reserved. Designed and Developed by PenciDesign

Rigging Inspection Boats Checklist: Essential Steps for Ensuring Safety and Performance

Key Takeaways

- Essential rigging checks for safety and longevity.

- Inspect both external and internal components.

- Maintain peak performance with regular assessments.

- Verify safety equipment readiness promptly.

When it comes to ensuring the safety and reliability of your vessel, a Rigging Inspection Boats Checklist stands as a pivotal tool. Rigging plays a fundamental role in a boat’s structural integrity and performance, making regular inspections an imperative practice for any seafarer or boat owner. This checklist serves as a comprehensive guide, meticulously detailing crucial components to examine, ensuring that each facet of the rigging system is thoroughly assessed for optimal functionality and safety compliance.

- Boat Rigging Inspection Essentials

Mast and Boom Inspection

Shroud and stay examination, spreaders and spreader bar evaluation.

- Turnbuckle and Clevis Pin Check

- Rigging Tension Assessment

- Final Rigging Inspection Steps

Rigging Inspection Boats Checklist: Essentials

Thorough scrutiny is essential during a meticulous boat maintenance checklist , particularly when conducting a comprehensive Rigging Inspection. Evaluating the sailing rigging’s integrity is paramount, with a focus on detecting signs of wear, especially around rigging hardware and shackle jaws. Pay close attention to stainless steel shackle pins, checking for any sliver of screw threads or excessive wear that could compromise their strength.

Don’t overlook the significance of vital fasteners—even the smallest discrepancy could demand immediate emergency repairs. Keep an eye out for irregularities, such as using a plastic wire tie where a more robust solution is required. Beyond rigging, ensure that even seemingly unrelated elements like engine oil don’t pose a threat to the rigging system’s functionality. This methodical scrutiny guarantees the utmost safety and reliability of your vessel.

Inspect the mast and boom for any signs of damage or wear before setting sail. That is an essential step in ensuring your boat’s safety and smooth operation. Start by examining the standing rigging, which includes the wires and cables that support the mast. Look for any visible wear, such as fraying or corrosion. Pay special attention to the fittings and connections, checking for any loose or missing cotter pins. These small pins are crucial in securing the rigging and should be correctly shaped and properly sized.

Next, inspect the halyards, which are the ropes used to raise and lower the sails. Check for any signs of chafe or wear, especially near the attachment points. Look for any splices or knots that may have come loose. Ensure that the halyards move freely through their respective sheaves and pulleys.

Utilizing a rigging inspection boats checklist, shift your focus to the boom. Thoroughly examine it for cracks, dents, or signs of deformation, paying meticulous attention to the fittings and connections. Check for any loose or missing cotter pins and ensure the gooseneck and the connection between the boom and the mast are secure and functioning properly.

Before moving on to the shroud and stay examination, take a moment to ensure the mast and boom are in optimal condition. Once you have checked the mast and boom, it’s time to focus on the shrouds and stays. These crucial components connect the mast to the hull and support the rig. To ensure the safety and integrity of your boat’s rig, inspecting and maintaining the shrouds and stays regularly is important.

Here are three important things to check during your rigging inspection:

- Look for any wear or damage on the shrouds and stays. Inspect the wires for rust, corrosion, or broken strands. Any signs of deterioration should be addressed promptly to prevent further damage.

- Check that the turnbuckles are properly secured and that cotter pins or circle clips are in place and properly guarded. These components play a vital role in maintaining proper tension and alignment in the rigging.

- Pay attention to any signs of misalignment or uneven tension in the shrouds and stays. Ensure that all wires are properly tensioned and aligned to maintain the stability and balance of the mast.

Using a rigging inspection boats checklist, ensure the mast and boom are sound before focusing on shrouds and stays. Check for wear, rust, and misalignment; secure turnbuckles with cotter pins for rig stability. Regular inspections are vital for boat rig safety.

To ensure the safety and stability of your boat’s rig, it’s important to thoroughly evaluate the spreaders and spreader bar for any signs of cracks, wear, or improper attachment to the mast. Start by checking the alignment of the spreaders. They should bisect the shrouds at equal angles, ensuring proper load distribution.

Inspect the spreader tips for corrosion and potential cracking, as these can weaken the rigging. Verify that the spreader boots are securely in place to prevent chafing of the sails and potential damage.

Next, examine the spreader bar attachment points. Look for any signs of stress or wear, which could indicate a potential failure point. Ensure that the spreader bar is securely connected to the mast, using appropriate hardware and fittings. Any looseness or improper attachment should be addressed immediately to prevent accidents or damage to the rig.

- Marine Surveying St. Augustine, FL

- Marine Surveying, Thermal Imaging & Consulting

- Offshore Outfitting

- Presentations

- Thermal Imaging

- Ultrasound/Audiogauge

- Inspecting Sailboat Rigging

Rust is often a sign of crevice corrosion.

OLYMPUS DIGITAL CAMERA

Uncategorized

chainplate Crevice Corrosion Sailboat rigging

Recent Posts

- Trawler Fest 2016

- Carbon Fiber Rudder Inspection

- Inspecting Chainplates

Moisture trapped in a rudder

Delamination

- February 2016

- December 2015

- August 2015

- February 2015

- October 2014

- August 2014

The Yacht Rigger

Empowering Your Marine Adventures

Advanced Alternator Regulator

#1 Authorized Rainman Distributor in the USA

We’re committed to offer the lowest Rainman prices in the US!

Marine Solar & Electrical

Marine solar installations on all vessels

DIY Marina Wet Slips & Haul-Out Facilities

Slips can accommodate catamarans up to 55' with beam limitations at 30'

New Youtube Series

Join us as we venture into the world of Marine Professionals! Like Share & Subscribe!

The Yacht Rigger is a marine specialist group dedicated to marine upgrades and maintenance. From rigging, electrical, lithium batteries, solar, custom metal fabrication, air conditioning, deck hardware and much more.

We specialize in all types of yacht rigging, whether your boat is for cruising or racing, our team provides a comprehensive unbiased service tailored around you and your vessel. Please explore our services and products pages to discover what we have to offer.

Meet the crew

Featured Services

Rigging & lines, solar & electrical.

- Sailboat Arches

HVAC & Refrigeration

Quality brands.

High quality brands namely Blue Wave, Selden Furlex, Ewincher, Rainman, Spectra, Mantus, Harken, Waterline Design and more. We are currently expanding the store so keep an eye out.

Quality Services

At The Yacht Rigger we pride ourselves in offering top quality service, installation, and maintenance to a wide range of products and brands. Have a look at our lit of services below.

Marine Solar & Electrical Systems

The Yacht Rigger is proud to be the premier choice in Florida for marine solar installations on all vessels, from sailing catamarans, to cruising mono-hulls, to power cats and small motor trawlers. We’ve got your solar & electrical needs covered. Including new system installation, existing system troubleshooting, parts replacement, new system integration or additions, new battery banks and much more. Let our partnered ABYC certified technicians come out to take a look at your electrical needs and we’ll make sure you have an efficient, well integrated system up and running in no time.

Standing Rigging Production Facility

With our Wireteknik A350 swage machine and a production shop full of swage fittings, spools of KOS Stainless steel wire and wire rope, and brand new chrome bronze turnbuckles by the dozen, we can produce standing rigging from lifeline size – up to 5/8″ (16mm) standing rigging. Competitive pricing and top quality parts mean your new standing rigging will be safe for many years to come.

We have a very large inventory of Blue Wave standing rigging components on hand at all times. See our Blue Wave page for more details on this top quality Danish supplier.

We ship anywhere, so send us your orders for standing rigging and we’re happy to produce your rigging and ship it out to you, or come see us at the boat yard!

Lifeline Rigging

If you need your Lifeline rigging replaced, look no further. We offer full service Lifeline rigging replacement. We only use top of the line marine grade stainless steel products, and our A350 swaging machine can handle swaging up to 5/8″ (16mm) wire.

Let our team renew your Lifeline rigging and get back out on the water sailing safely.

Marina Wet Slips & Haul Out Facilities

In our wet slips we can accommodate catamarans up to 55′ with beam limitations at 30′. We have a large float bag on site for service work on catamarans such as thru-hull installations, sail drive removal, propeller work, and underwater light installations.

On the hard we are limited to a 16′ beam for haul out and offer full service bottom jobs as well as gelcoat repairs, propeller and shaft replacements, and even re-power projects (and more).

We do offer do it yourself “DIY” yard spaces, as well as DIY wet slip spaces, and all our wet slip spaces allow liveaboard and offer bathrooms with showers and laundry facilities.

Solar Frame & Arch Fabrication

We utilize the latest state of the art solar panels and build custom frames in house out of light weight marine grade bright anodized aluminium. (Stainless steel frame fabrication is also available if requested). Our goal is to maximize your vessel’s solar potential whilst maintaining minimalist concepts to create a beautiful, and highly functional end product.

Custom Frames Arches

Rigging Inspections & Consultations

The Yacht Rigger provides comprehensive rigging inspections on all masts to vessels located within our service area. We inspect all running and standing rigging. All rigging termination points are visually inspected. Sheave pins and sheaves inspected, spreaders, furler or headsail foils, and all gooseneck fittings. Electrical wiring is inspected for chafe/corrosion.

We also check all light fittings, blocks, cars, tracks, clutches, winches and any other hardware. A complete cleaning of all rigging ends, pins, and cars can be added if the mast is going into storage. We provide a detailed report of our findings, including suggestions for any additional parts and work required.

At the Yacht Rigger we also offer a consultation service designed to assist you with both troubleshooting as well as with selection of any new rigging parts, from winches or furling gear, to a new mast, no job is too big or too small. Please visit our Contact Us page and get in touch so that we can assist you!

HVAC (heat, ventilation, air conditioning) systems, helps to control the climate on your boat allowing you and your crew to enjoy the time on board all year long. Not only control the temperature on cold winters or hot summers, they also control the humidity levels, making the living area feel more comfortable and helping to keep the boat dry, increasing the life of electronics, fabrics, headliners, etc. reducing mold growth and other moisture related problems.

Investing in a new installation or upgrade of an existing one will extend your boating season and increase the value of your boat.

Winch Servicing

Servicing your winches regularly not only improves their longevity, but also greatly improves performance. Correctly cleaned and lubricated winches will operate faster, and require less force when grinding.

We can service all of your winches professionally, on site, in a matter of a few hours. We carry parts for most major brands and can source parts for almost any winch out there today.

Our riggers are highly competent splicers, capable of splicing any line in a given application. From basic polyamide docklines, to covered Vectran, we can assist you in selecting the correct line for the correct application. Be it a weight saving halyard for a race boat, or a topping lift for a cruiser, look no further than TYR.

Hardware Installation

At TYR we can supply all hardware relating to your mast and deck, for all brands of masts. Our team of expert riggers will guide you through getting the right equipment for your boat.

We supply many top of the line models of headsail furlers, including Selden Furlex and Harken. TYR can also provide servicing and spare parts for existing systems to ensure efficiency and reliability.

We supply a full range of blocks, clutches, cars and travelers from the leading brands Spinlock, Harken, Selden, and Ronstan. Be it a cruising boat wanting to maximize ease of use for all of running systems, or a high performance dinghy or racing yacht wanting to minimize weight, we will provide a product suited to your needs.

New Sails & Sail Covers

If you’re considering replacing your sails or sail covers, please get in touch with us through our contact portal. Our team has decades of experience in both cruising and racing and we’ve partnered with the most talented and detail oriented sailmakers and canvas specialists in the Tampa Bay area to offer you a comprehensive sail replacement service.

Our sail replacement service includes: Consultation – we’ll help you choose the sail material and cut that best suits your needs.

Measurement – if you fall within our service area we’ll come out to your boat and take precise measurements to make sure that your new sails perform optimally. We’ll also advise you regarding the variety of sail covers, mainsail storage systems, and sail furling systems available.

Installation – when your crisp new sails or sail covers are ready we’ll come out to your vessel and install them, to make sure they fit and perform exactly as needed.

Stern Arch & Davit Systems

If you are looking to store your tender on your stern, we have you covered. From large stern arches to smaller davit systems. We’ve partnered with suppliers from across the US to bring you the most cost effective, aesthetically pleasing, and practical solutions to this complex issue. We can also supply fully integrated solar and wind systems on top of our stern arches that will get you off the grid and ready to go out into the big blue!

Anchoring & Windlass Systems

We supply and install new windlasses, anchors, anchor chain, rode, and all the accessories in between. We can fabricate custom mounting platforms, install all the necessary switches, wiring, fuses, and additional batteries if needed.

Marine Electronics

At The Yacht Rigger we offer a comprehensive marine electronics service that includes new system installation, existing system troubleshooting, parts replacement, new system integration or additions, new battery banks and much more. Let our partnered ABYC certified technicians come out to take a look at your electrical needs and we’ll make sure you have an efficient, well integrated system up and running in no time.

Google Reviews

“ “ Stephen does regular work for me on rigging. He is very knowledgeable and dependable. First rate! ” Robert K

“ “ Steve and his crew listened to what we needed, then stopped by our just purchased 1997 Catalina 38 to look it over. In 10 minutes they diagnosed the issue, proposed a solution, removed the sail, gave me an estimate on money and time and off they went. Came in right on budget, hit the completion date on the mark, sent me photos to see the final product. Thoroughly professional and timely. I'd recommend these guys anytime, an will have them back on our boat as we need them for sure. ” Mike Conroy

“ “ Extremely knowledgeable in repair or upgrades to not just rigging, but all systems of sailboats. Professional and prompt service. These guys have helped my wife and I outfit our boat for live aboard cruising. From rigging replacement to solar panel install and also repair of systems specific to our boat, we couldn't have done it without them. Fair, reasonably priced, and always available for questions. 5 stars plus, nothing more I can say. ” Zach Duncan

“ “ These are the most professional guys I've met in the marine industry in St. Pete. They were very helpful in getting my boat ready for passage on a tight timeline. The job was done in time and on budget, but what really sets them apart is the fantastic communication. Highly recommend! ” Nate Mortensen

“ “ Great service. These guys are very knowledgeable. ” Pat M

Recent Posts / View All Posts

Contact number

We are monthly supporters. click below to donate..

- HVAC & Refrigeration Services

- Marine Solar

- Marine Electrical Systems

- Solar Frame Fabrication

- Standing Rigging & Forms

- Running Rigging & Forms

- Lifeline Rigging & Forms

- Anchor Chain & Rode Form

- DIY Marina Wet Slips

- Haul-Out Facilities

- Stern Arch & Davit Install

- Blue Wave USA

- Cyclops Load Sensors

- Robline Ropes

- Marlow Ropes

- Mantus Marine

- Tides Marine – SailTrack

- Anchor Chain and Rode

- Waterline Design

- Furlex Furling Systems

- Selden GX & CX Furlers

- Selden SMF System

- Bamar Products

- Hood Furling Systems

- Victron & Solar Panel Store

- Kilovault Batteries

- Custom Fabricated Frames & Arches

- Mabru Air Conditioners

- Velair Air Conditioners

- Rainman Watermakers

- Spectra Watermakers

- RuuviTag Pro

- Integrel Solutions

- Manuals/Catalogues

- Account details

Salt Creek Marina and Yard Rules & Regulations (DIY & Storage)

“Common Sense, Compliance with Laws, Consideration Toward Others” (January 1, 2023)

This agreement shall be effective on the date hereunder by and between the undersigned Owner or Agent of the vessel(s) hereinafter (“Vessel Owner”) described below and Salt Creek Marina, Inc. and The Yacht Rigger LLC located at 107 15th Ave SE, St. Petersburg, FL 33701.

8/21/2023 UPDATE – If a hurricane system becomes a named storm and your boat is in one of our wet slips you MUST move it back to its original berth. The boat is not allowed to stay. The owner is responsible for planning with their preferred captain, or The Yacht Rigger has two captains on staff.

1. Fees: The Yacht Rigger and Salt Creek Marina reserves the right to change its rates upon one (1) months’ notice.

- Monohull DIY Dry Storage will be $900 monthly or $225 weekly, with a minimum of 1 week required. After the first 4 weeks, the rate will increase by $50 per week, for the remainder of the boat’s duration.

- Monohull Wet Slip will be $1,100 monthly or $275 weekly, with a minimum fee of $100.

- Catamaran Wet Slip will be $2200 monthly or $550 weekly.

- Haul / Block / Relaunch – One Time Charge $12 per foot

- Emergency Haulout – $25 per foot

- Short Haul – – – Special Haul to be scheduled by The Yacht Rigger or approved contractor only + $175 contractor fee (includes normal haul out rate)

2. Insurance: Vessel owners must provide insurance with Salt Creek listed as additional insurer on their vessel before arrival. Vessels must always be insured.

3. Hurricane & Summer Storm Season: June 1 – November 30 Haul out boats for storage or DIY work on the hard during this time are required to remove all canvas (including but not limited to Bimini, sail covers, dodgers, e.g.) as well as all sails on the boom or furlers. Remove all moveable equipment: canvas, sails, dinghies from davits, cushions, water toys, grills, biminis, roller furling sails, etc. Canvas and sails must be stored below and not on deck. Lash down everything you cannot remove tillers, wheels, booms.

4. Live Aboard – Wet Slip Only (Yacht Rigger Only Rule): Starting January 1st, 2024, customers may NOT stay on their vessel during electrical refit work or other major modifications or upgrades down below. Due to the nature of these projects requiring major upheaval down below within your living space and the need for our teams to work efficiently. Rigging and “above deck” type work will permit liveaboards. As much as we would love to accommodate liveaboards during this time, it is simply too inefficient for us and expensive for you, the customer. For vessels with excessive items on board preventing efficient work, we will provide on-site storage pods at market rates.

5. Third Party Warranties: This includes any warranty claim that is to be made against the original manufacturer or seller of the vessel or product. Should a warranty claim arise, The Yacht Rigger will estimate the job accordingly. It will then be up to the customer to obtain approval from the applicable 3rd party (boat manufacturer, spar manufacturer, etc.). If approved & immediately upon completion of the warranty issues, the customer is solely responsible for the payment of the work completed. It is then the responsibility of the customer to be reimbursed by the applicable 3rd party.

6. Yard Hours: The boatyard hours are 8:00am to 6:00pm, Monday- Sunday. The boatyard gate locks at 6:00pm. You may come check on your vessel, re-secure rigging, canvas and pump out water during business hours. Please check in with the office if you are near closing hours.

7. Utilities: Boatyard provides power & water to vessel owners as a part of their agreement so long as the owner fully adheres to all Rules and Regulations. When you are finished with the water hoses, turn them off and place them back neatly in the area you found them. Please ask a Salt Creek Marina Boatyard Employee for access to either option.

8. Outside Contractors/ Subcontractors With Management approval (determined individually) contractors may work on a storage vessel for a fee of $40 a day in addition to monthly storage/dockage fee. The owner shall be responsible for informing the office of any subcontractor working on the vessel for any purpose whatsoever. The subcontractor shall submit insurance before any work can commence. Salt Creek Marina and/or The Yacht Rigger reserves the right at its sole discretion to stop unsafe work practices and if deemed necessary to order the offending worker(s) to leave the site at the Owner’s/Skipper’s sole risk and expense.

9. Supplies: All paint including but not limited to, bottom paint, primer or barrier paint, haul or topside paint, varnish or otherwise any paint being applied to your vessel must be purchased through the Boatyard or approved by Management. This policy is for safety and environmental protection purposes of all persons operating in the Boatyard. Paint will normally arrive within 24hrs of purchase.

10. Paint Spraying: There shall be no spraying in the Boatyard under any condition. Any person spraying any paint will be immediately expelled and fines levied.

11. Cleanliness: All vessel owners shall be responsible for keeping their area clean and professional. The Boatyard reserves the right to charge the vessel owner for any cleanup required to comply with RR. All debris associated with boat repair activities must be disposed of daily. A dumpster is located near the parking area.

12. Disposal: There is a designed disposal station of 55 gal drums for oil and one for oily rags and filters located near the office door. PLEASE DO NOT PUT GASOLINE IN THESE DRUMS.

13. Facilities: Bathrooms are provided as a courtesy to all Customers. We will make our best efforts to keep it clean but reserve the right to limit access any time. Please use the outside sink for heavy clean up and use the indoor head/sink for bathroom purposes only. The Yacht Rigger has its own set of facilities to be used by its staff and customers. Please do not use SCM facilities.

14. Parking: Park in the designated parking area. Vehicles should be parked clear of travel lift path, not in storage areas, on the seawall or blocking boats. Salt Creek Marina and/or The Yacht Rigger is not responsible for vehicles that are damaged by equipment or conditions in the yard

15. Regarding noise outside of the scope of work not being completed, i.e., radio/stereo volume, please be respectful of neighboring boat owners’ tenants.